Spring-loaded brake cylinder having locked stop body

一种弹簧蓄能、制动缸的技术,应用在商用车领域,能够解决困难、增加安装等问题,达到降低制造费用、节省空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

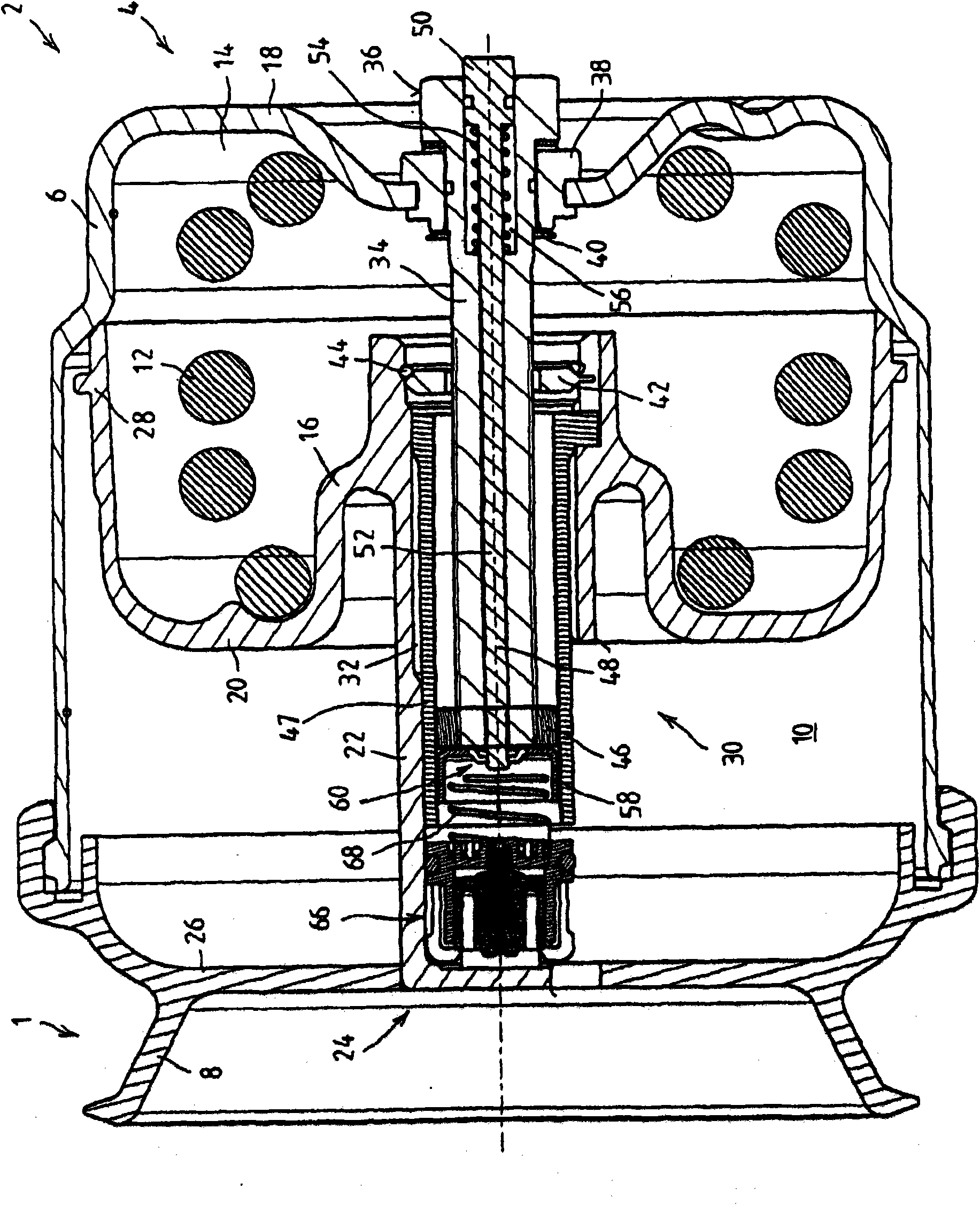

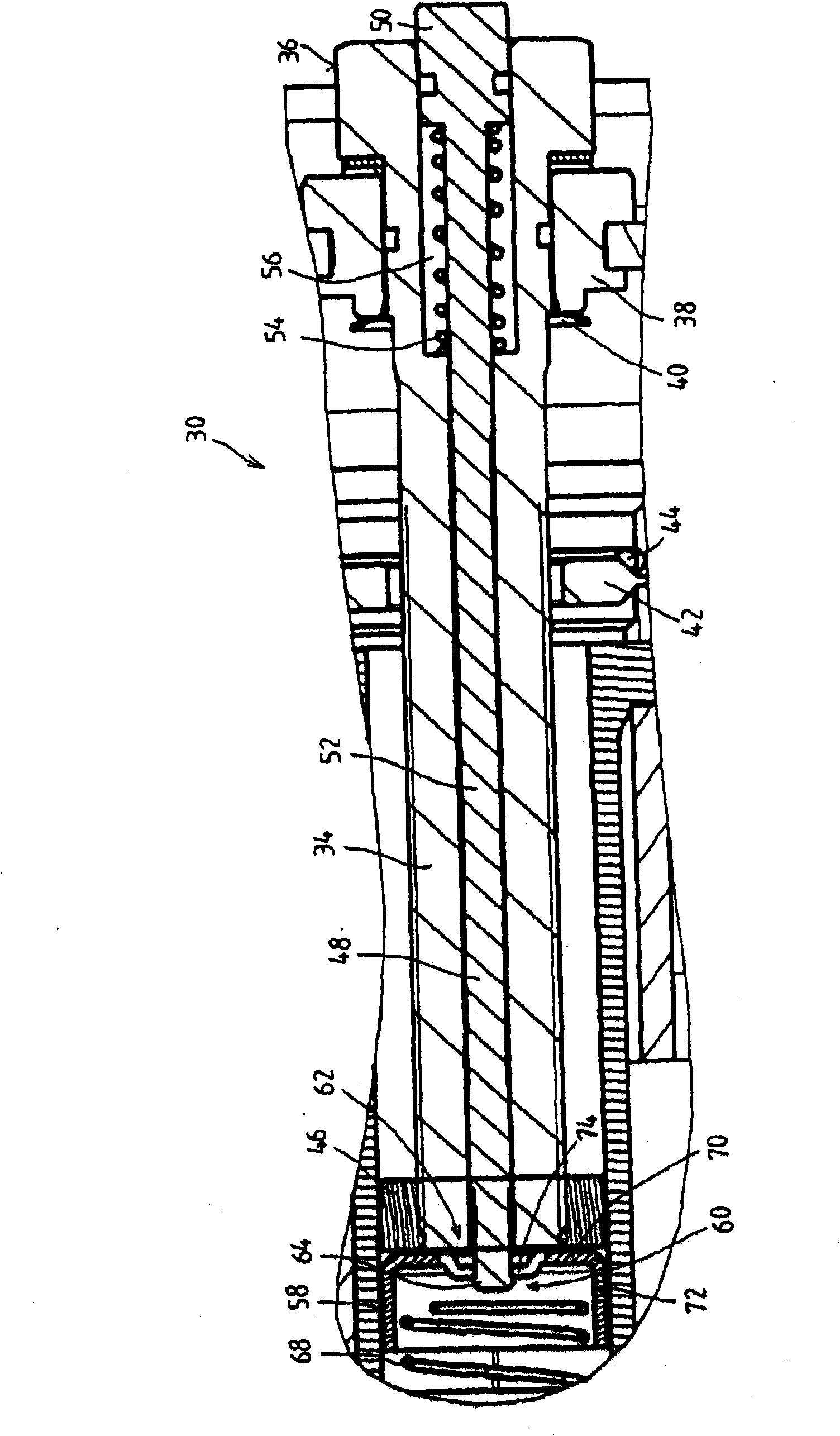

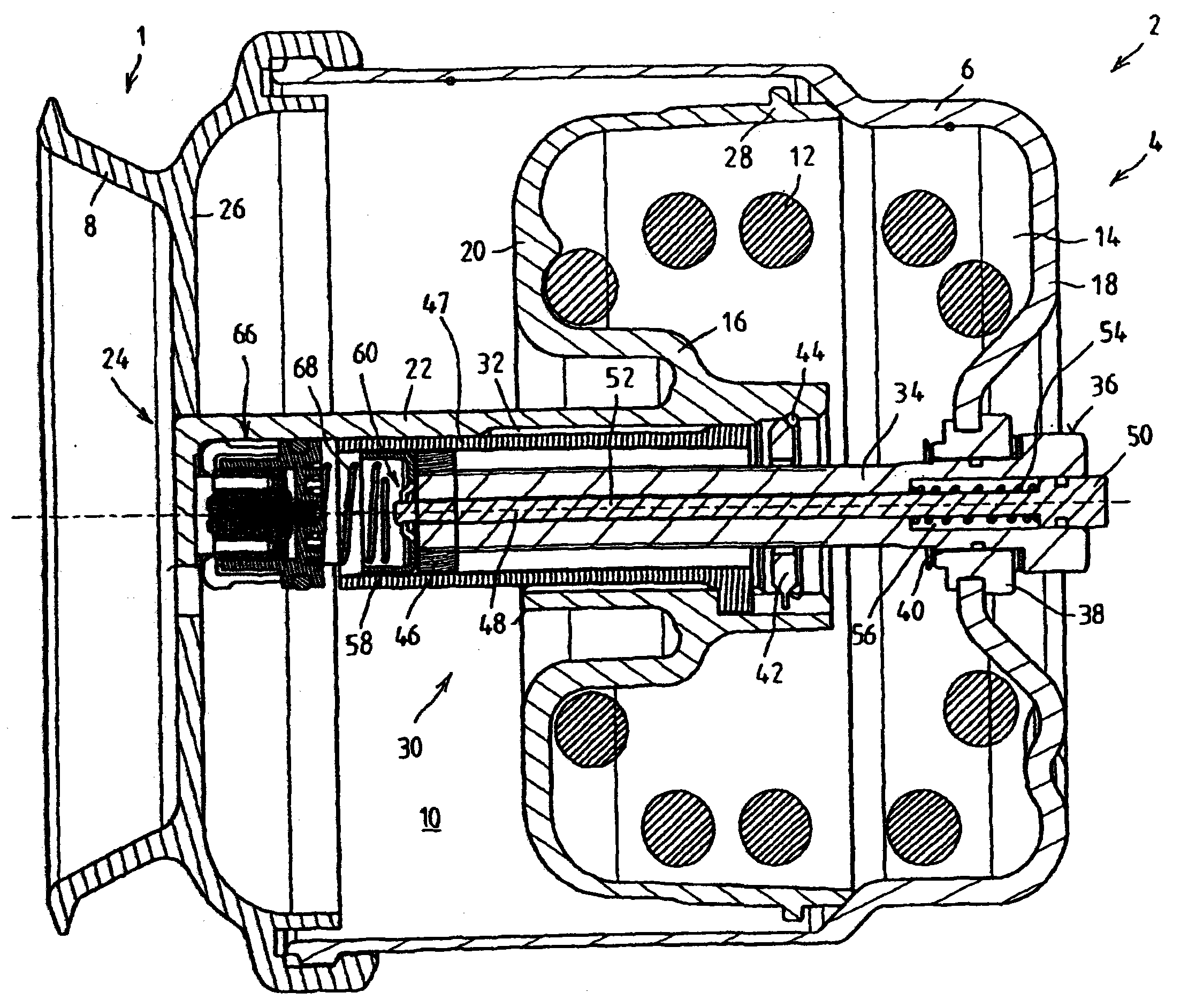

[0023] exist figure 1 shows a detail of a combined service brake cylinder and spring-charged brake cylinder 1 (combined brake cylinder) of a pneumatic or electro-pneumatic brake system of a commercial vehicle. It comprises a service brake system (not shown in the figure), which has a service brake cylinder with a housing, in which a pneumatically loadable service brake piston is guided, the service brake The brake piston actuates eg a disc brake of a commercial vehicle via a service brake piston rod.

[0024] Combination Cylinder 1 is also included in the figure 1 The spring energy storage brake device 2 visible in the figure has a spring energy storage brake cylinder 4 with a housing 6 on which a flange 8 is connected so that the housing 6 and the flange 8 constitutes a substantially closed unit. For example, a service brake cylinder can be attached to the flange 8 . In the housing 6, the spring-charged brake piston 16, which can be clamped by the pneumatic pressure in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com