Sinker device of flat knitting machine

A technology of sinkers and flat knitting machines, applied in textiles and papermaking, weft knitting, knitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

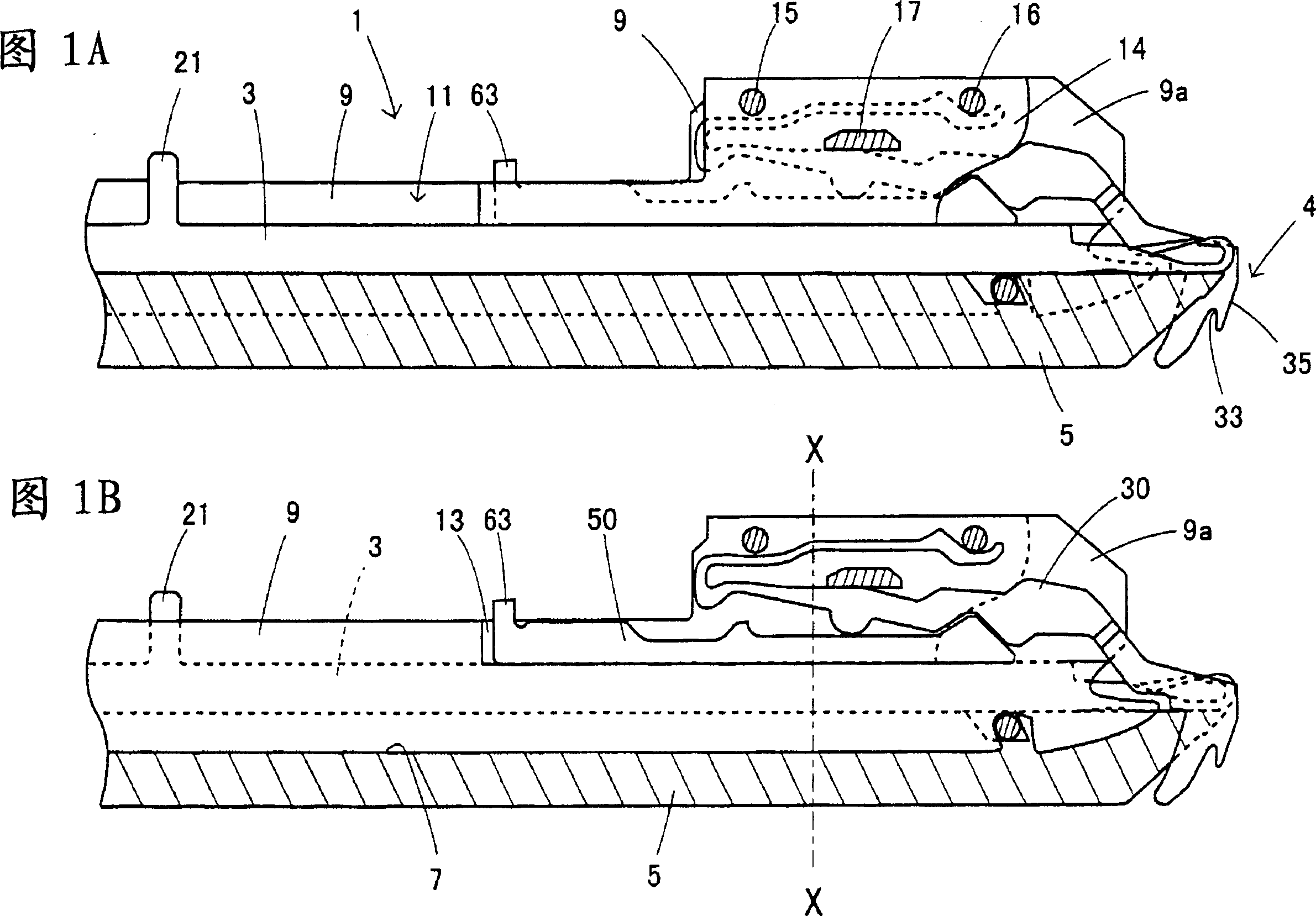

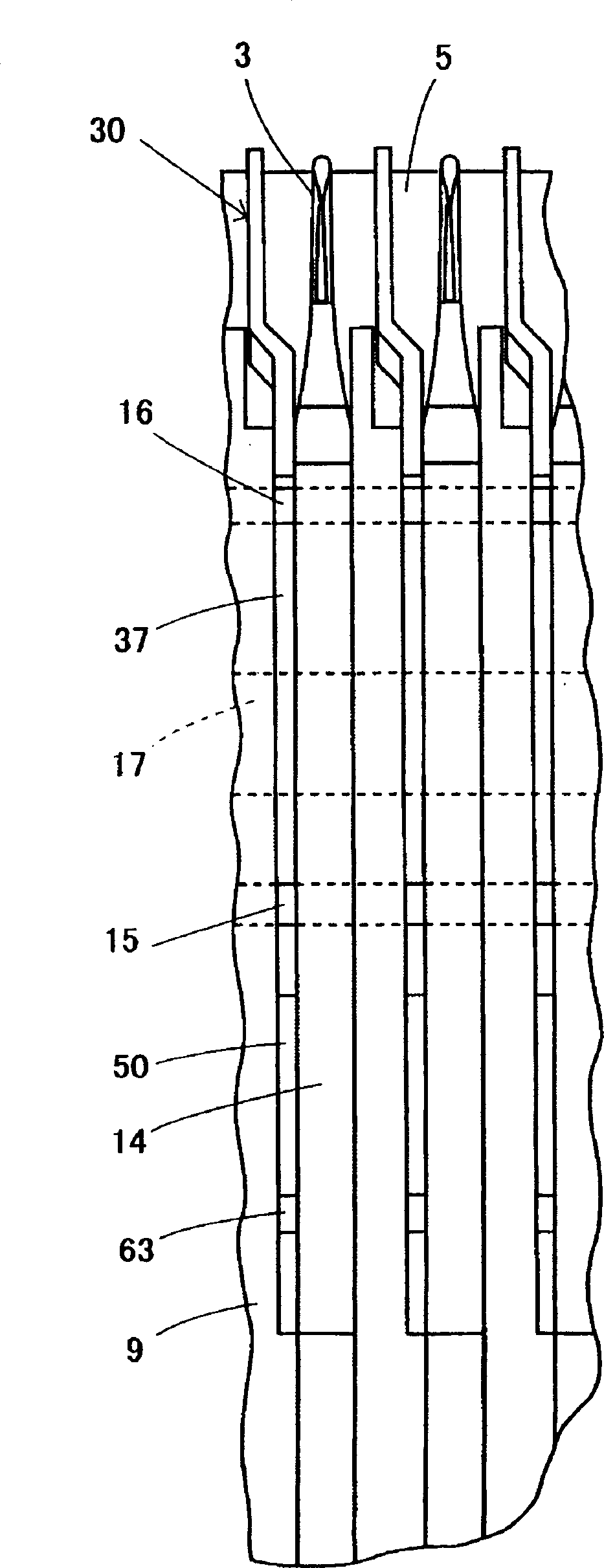

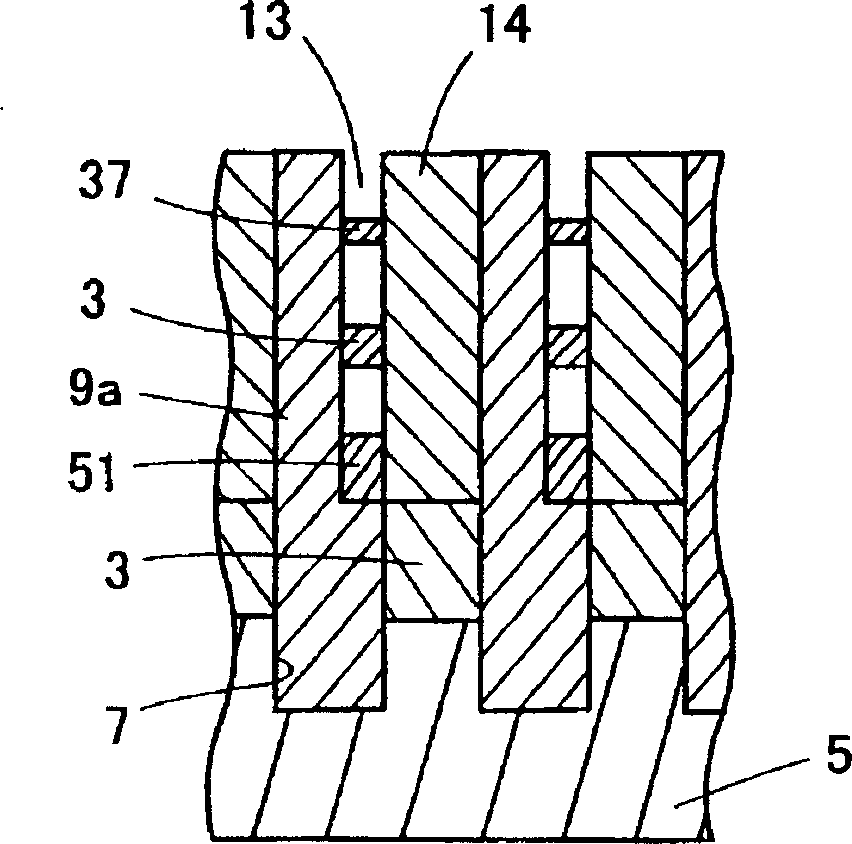

[0024] The best embodiment of the sinker device of the present invention will be described in detail below together with the accompanying drawings.

[0025] In the sinker device of the present embodiment, the cross mechanism is as follows: the needle beds 1 provided with many knitting needles 3 are arranged oppositely in front and back with the teeth gap 4 sandwiched, and any one or both needle beds can slide along its length direction. Figure 1 shows only one side of the needle bed, where the latch needles are installed. In the needle bed 1 , a needle plate 9 is erected among a plurality of hooks 7 engraved on a base plate 5 . Knitting needles 3 are accommodated in needle grooves 11 between these needle plates 9 and 9 . The front part 9a on the needle mouth side of the needle plate 9 is formed to be one step higher than the other parts, and the sinker pusher 50 and the upper sinker 30 are accommodated in the housing part 13 formed by cutting off one side of this part. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com