Combined composite cross arm

A composite material and combined technology, applied in building types, buildings, towers, etc., can solve the problems of complicated installation of composite crossarms, increase the weight of composite crossarms and project cost, and achieve compact layout and reduce crossarms. Cross-sectional area and material amount, the effect of solving wind deflection flashover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

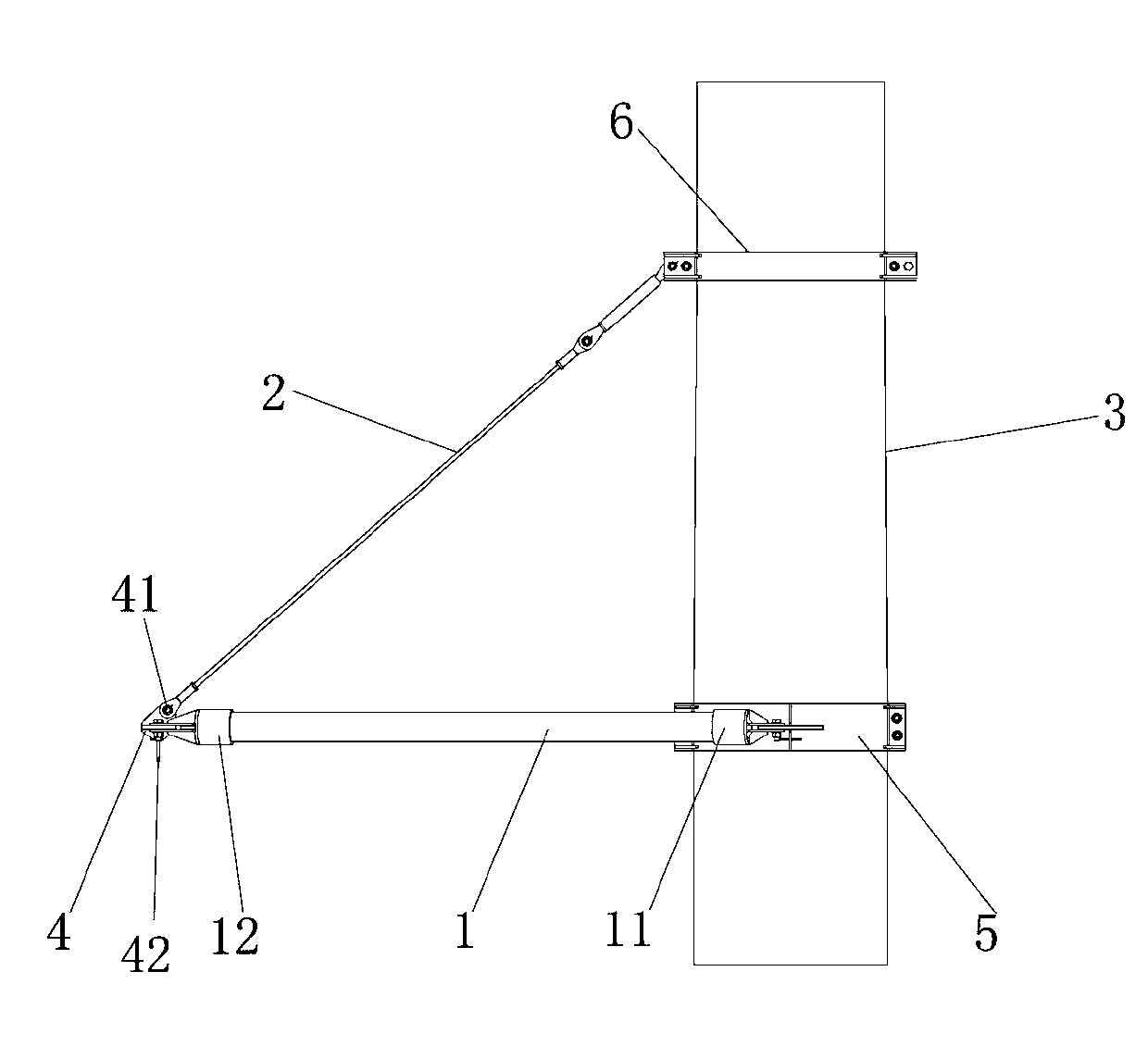

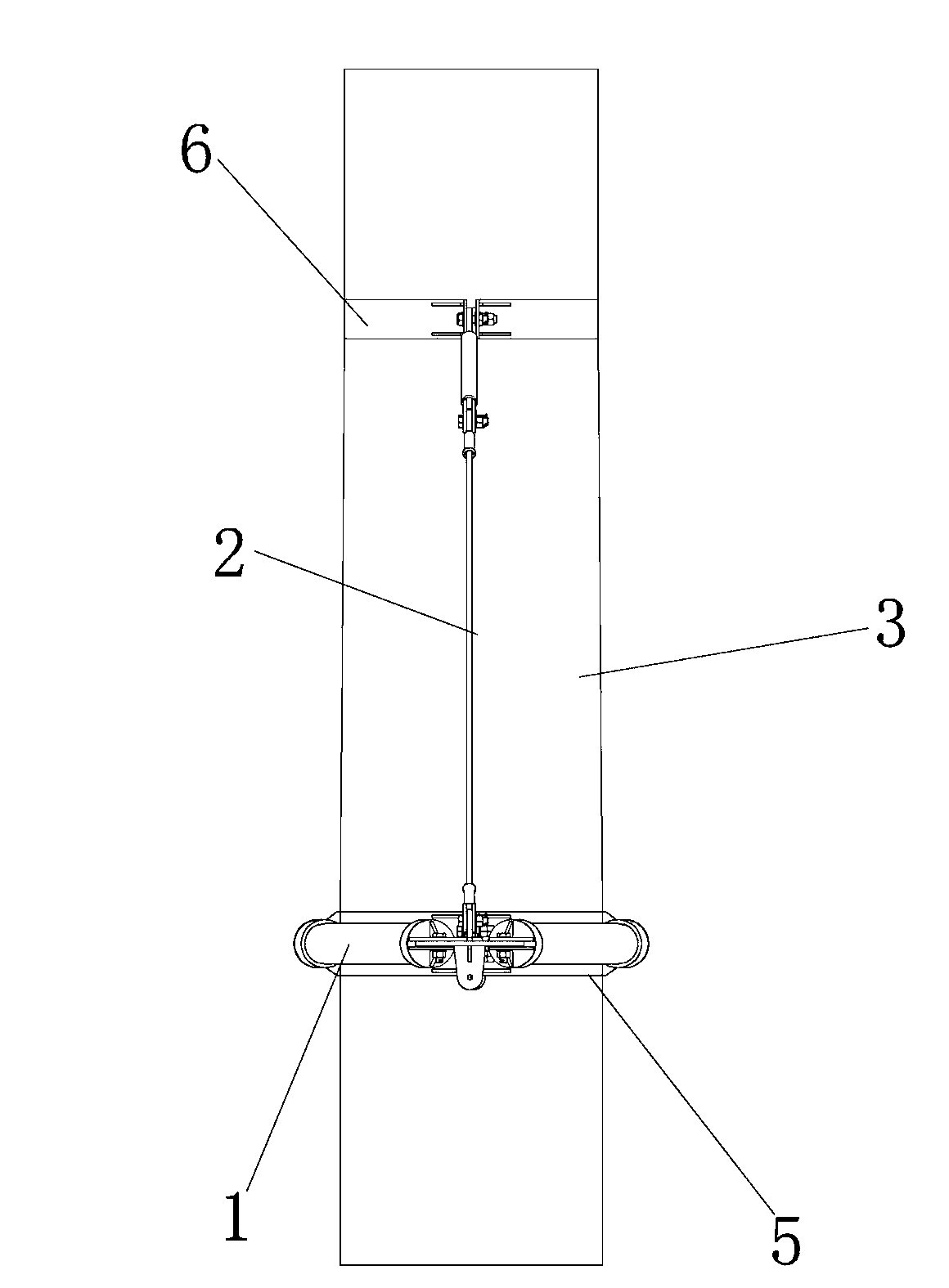

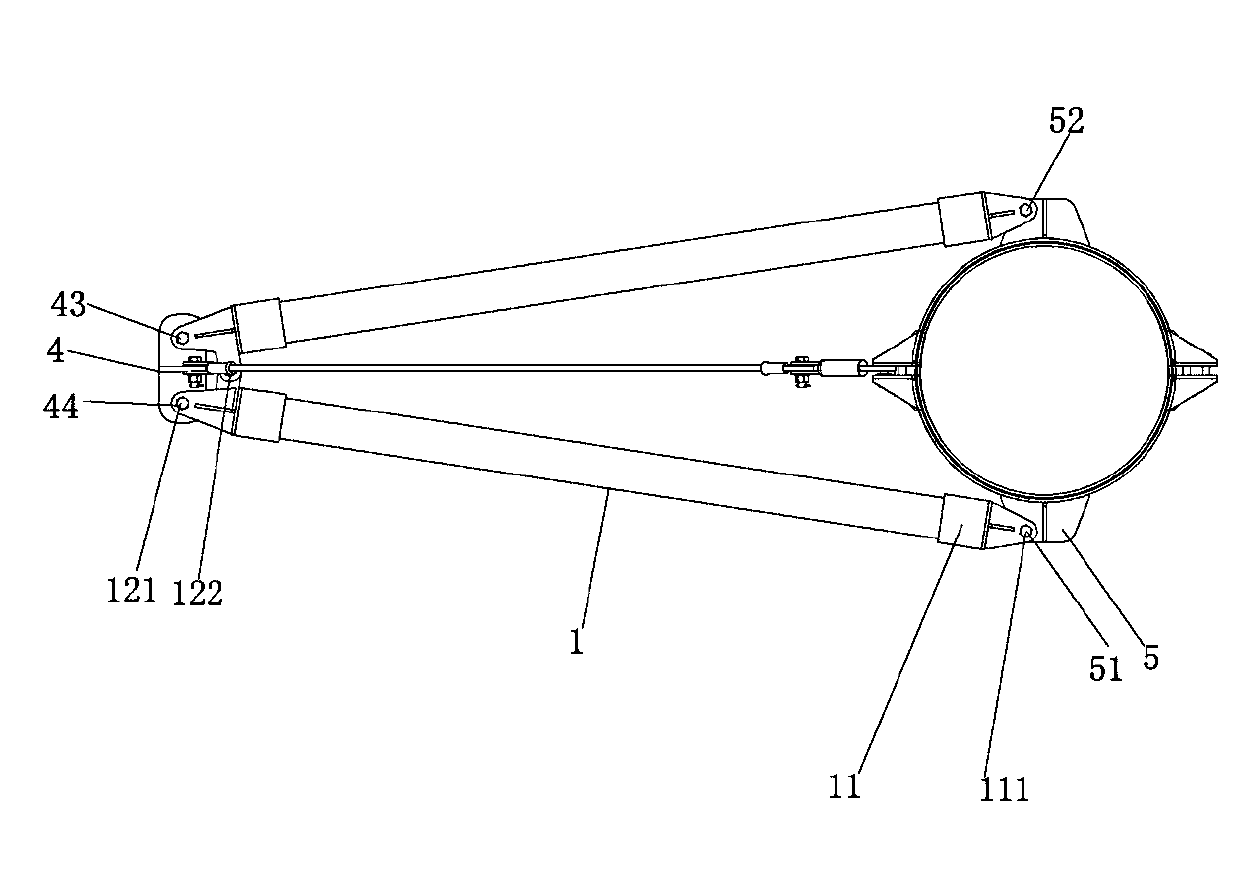

[0019] Such as figure 1 , 2 As shown, the combined composite material cross arm includes a tie rod hoop 6 and a cross arm hoop 5 which are set on the shaft 3 in the upper and lower order, two cross arms 1, a tie rod 2 and a hanging point 4, wherein:

[0020] The cross-arm hoop 5 is composed of front and rear semicircle structures, and the two semicircles are hugged on the shaft 3 by pressing bolts. A hinge hole 51 and a hinge hole 52 are respectively provided on the front and rear semicircles.

[0021] The top of the hanging point 4 is provided with a pull rod connecting hole 41, the below of the hanging point 4 is provided with a wire clamp hanging hole 42, and the left and right ends of the hanging point 4 are respectively provided with a hanging point connecting hole 43,44, and the pull rod 2 The bottom end of the pull rod 2 links to each other with the hanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com