Electric valve

A technology of electric valve and valve port, which is applied in the direction of valve lift, valve details, valve device, etc., which can solve the problems such as the deviation of the stop mechanism, and achieve the effect of reducing the number of parts, reducing the deviation, and stabilizing the stop position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

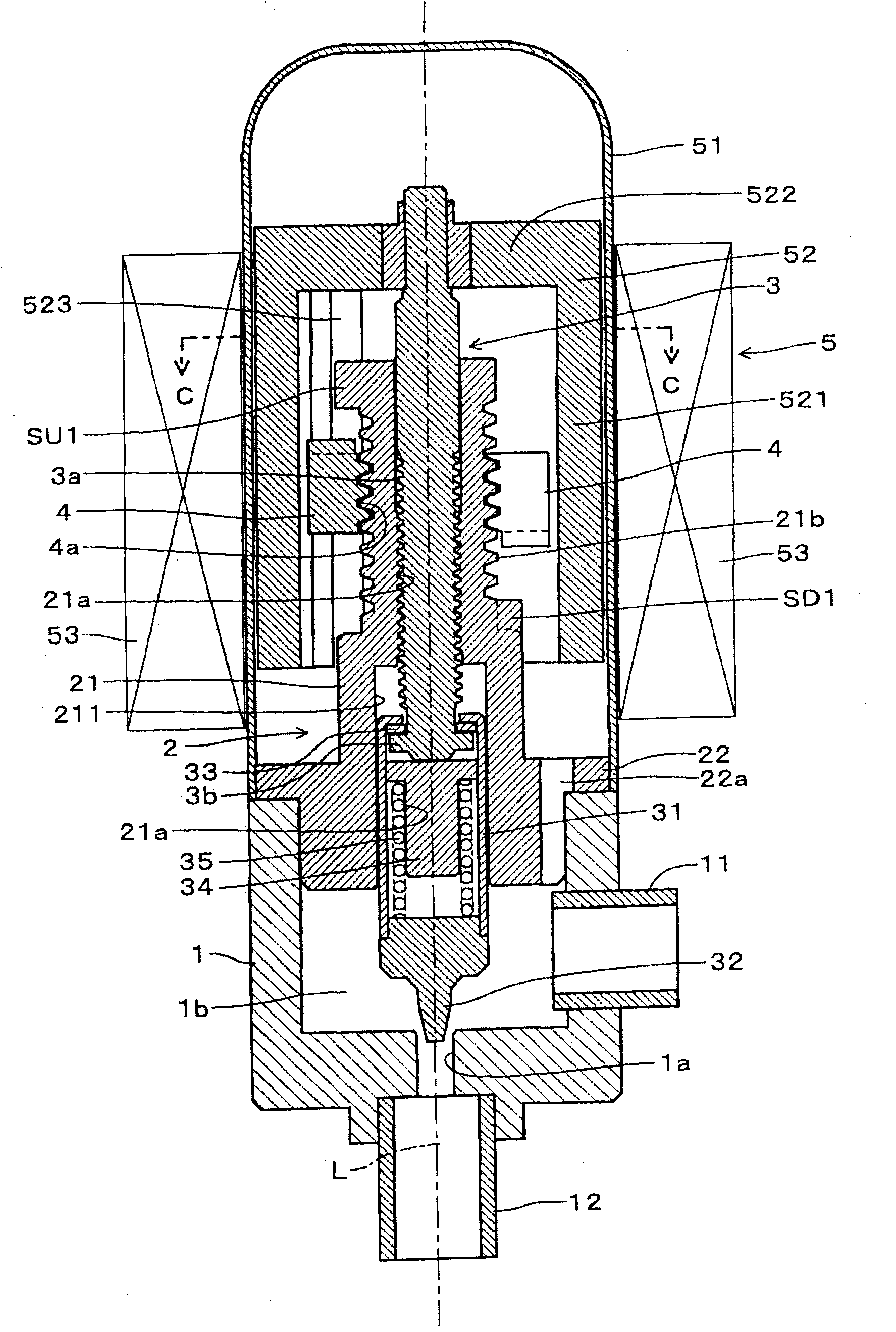

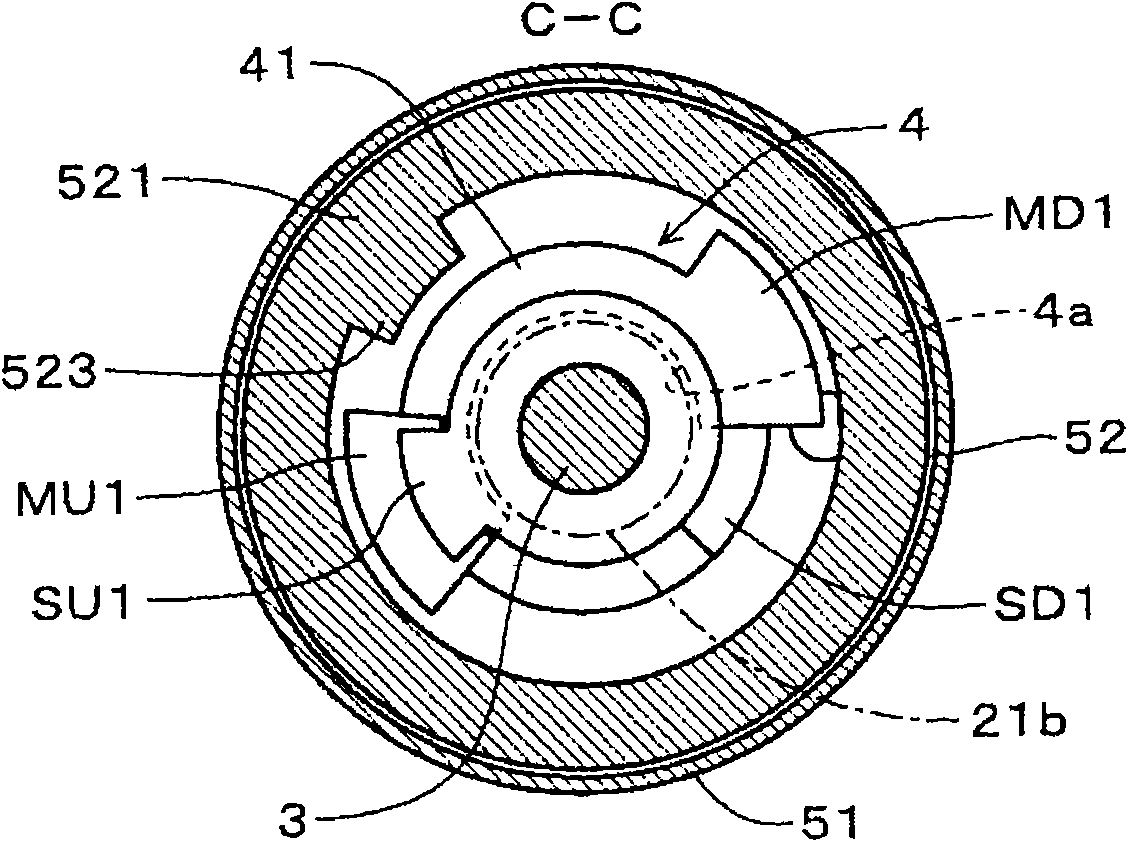

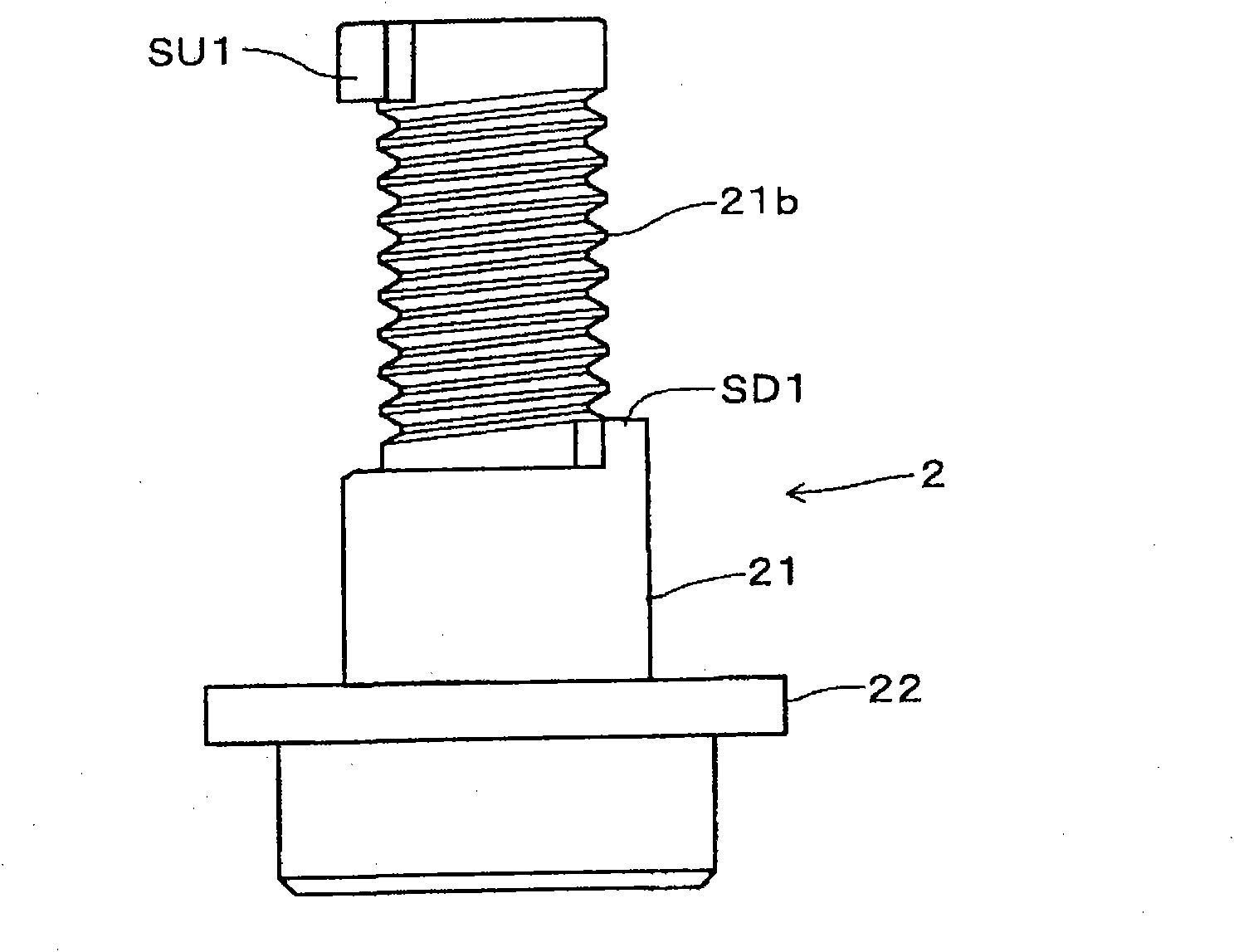

[0035] Embodiments of the electric valve of the present invention will be described below with reference to the drawings. In addition, in each of the following embodiments and modifications, the same elements as those in the first embodiment and corresponding elements are attached with the same symbols, and redundant detailed descriptions are omitted. figure 1 is a longitudinal sectional view of the electric valve of the first embodiment, figure 2 yes figure 1 C-C cutaway view, image 3 It is the side view of the appearance of the supporting part of the electric valve, Figure 4 It is the top view and longitudinal sectional view of the driven slider of the electric valve. In addition, the concept of "up and down" in the following explanations is the same as figure 1 The upper and lower correspondences in . This electric valve has a cylindrical valve body 1 . In the valve main body 1, a valve port 1a is opened at one end thereof. Moreover, the support member 2 is attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com