Method of making substrate for flexible circuit board

一种挠性电路板、基底的技术,应用在电路基板材料、印刷电路、印刷电路等方向,能够解决实际尺寸与设计尺寸改变等问题,达到抑制尺寸变化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-2

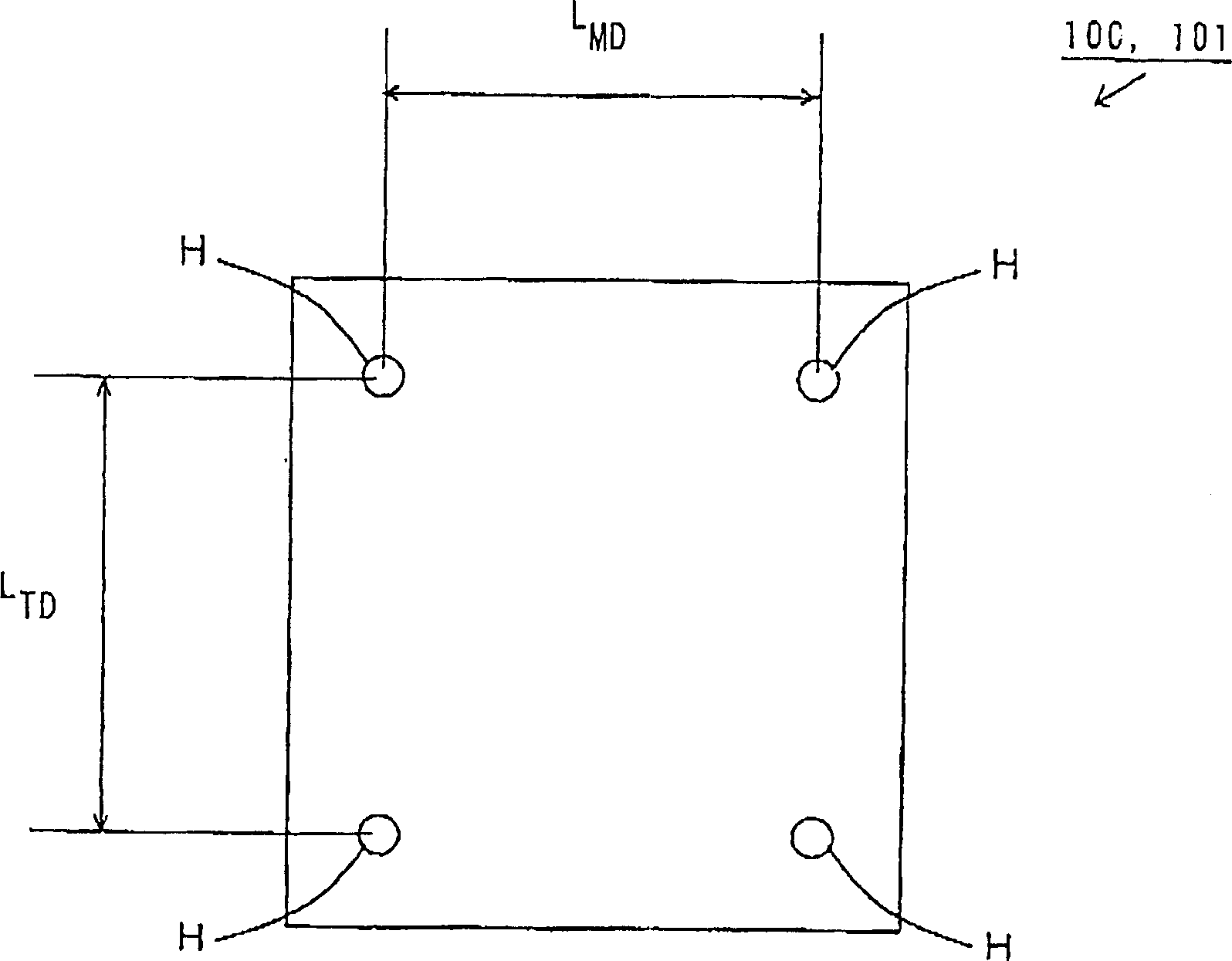

[0063] The flexible circuit substrates of Examples 1-3 were produced according to the first or second embodiment, and the flexible circuit substrates of Comparative Examples 1-2 were also produced. The metal foil 3 of the produced flexible circuit substrate was etched, and then the dimensional change of the flexible printed wiring board was evaluated.

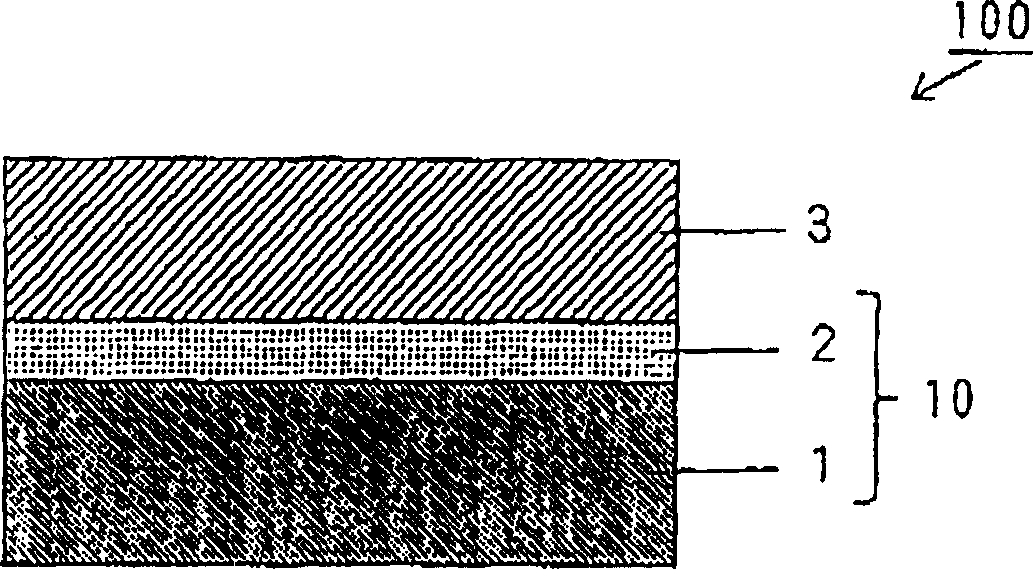

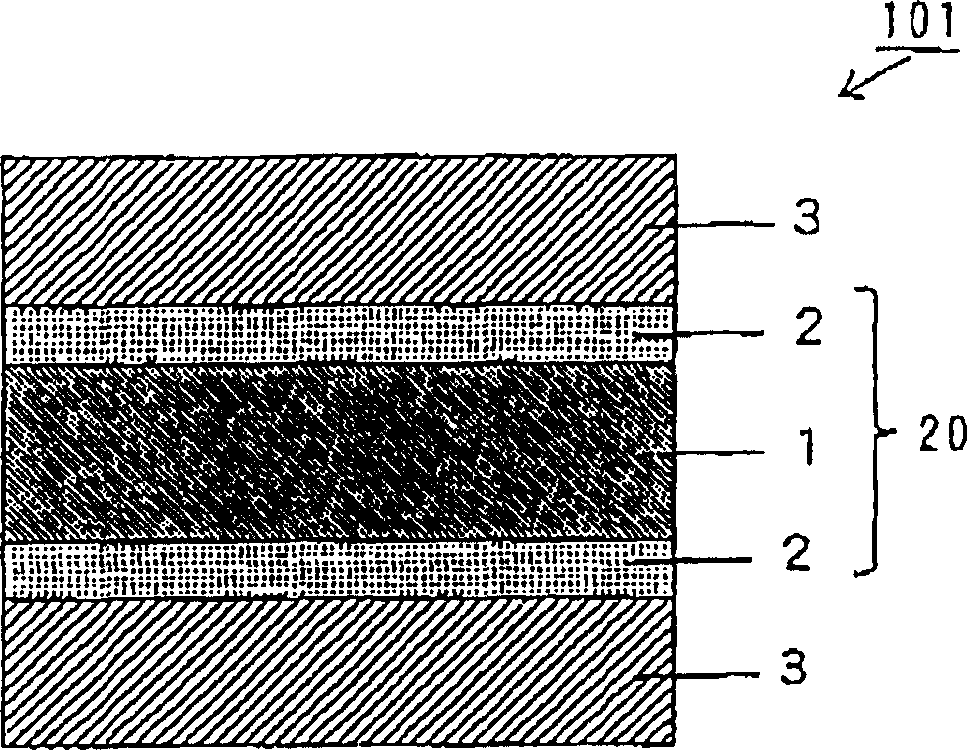

[0064] In Example 3 and Comparative Example 2, the substrate 100 for a single-sided flexible circuit board was used. In Examples 1-2 and Comparative Example 1, the substrate 101 for a double-sided flexible circuit board was used.

[0065] Table 1 shows the properties of the insulating layer 1 in each of the substrate 100 for a single-sided flexible circuit board and the substrate 101 for a double-sided flexible circuit board used in Examples 1-3 and Comparative Examples 1-2. Material and thickness (μm).

[0066] Table 2 shows the adhesive layer 2 of each of the substrate 100 for a single-sided flexible circuit board and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com