Polyimide film

A technology of polyimide film and film, applied in printed circuit, printed circuit components, printed circuit, etc., can solve problems such as anisotropic fluctuation, achieve the effect of suppressing dimensional change and improving appearance yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0051] One embodiment of the present invention will be described below.

[0052] The polyimide film used in the present invention can be produced by a conventionally known method using a solution containing polyamic acid.

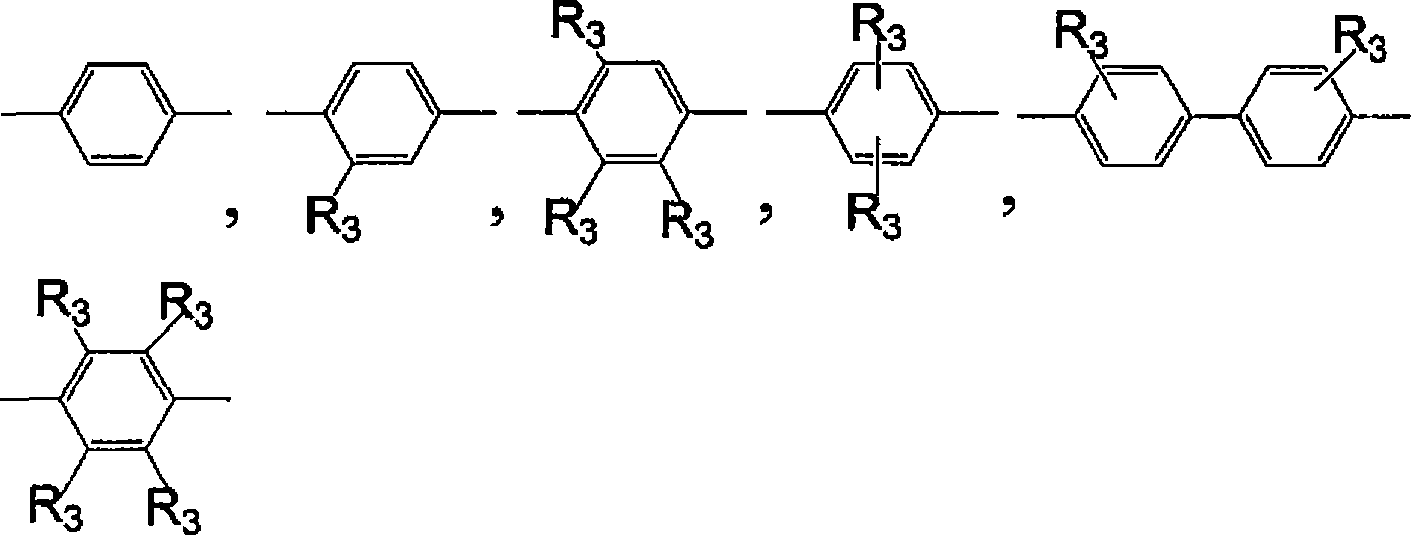

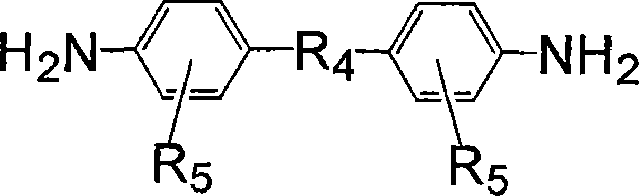

[0053] As a method for producing polyamic acid, any known method can be used, and it is usually produced as follows: substantially equimolar amounts of aromatic acid dianhydride and aromatic diamine are dissolved in an organic solvent, and The obtained polyamic acid organic solvent solution was stirred until the polymerization of the above-mentioned acid dianhydride and diamine was completed. These polyamic acid solutions are usually obtained at a concentration of 5 to 35% by weight, preferably 10 to 30% by weight. Appropriate molecular weight and solution viscosity are obtained at concentrations in this range.

[0054]As the polymerization method, any known method and a method combining them can be used. The polymerization method in the polymerization o...

Embodiment

[0160] Evaluation of the film in the present invention was performed as follows.

[0161] (Tear strength retention before and after PCT)

[0162] Measurements were performed before and after PCT treatment according to ASTM D-1938.

[0163] In addition, PCT treatment was performed on the conditions of 150 degreeC and 100%RH for 12 hours.

[0164] (slack)

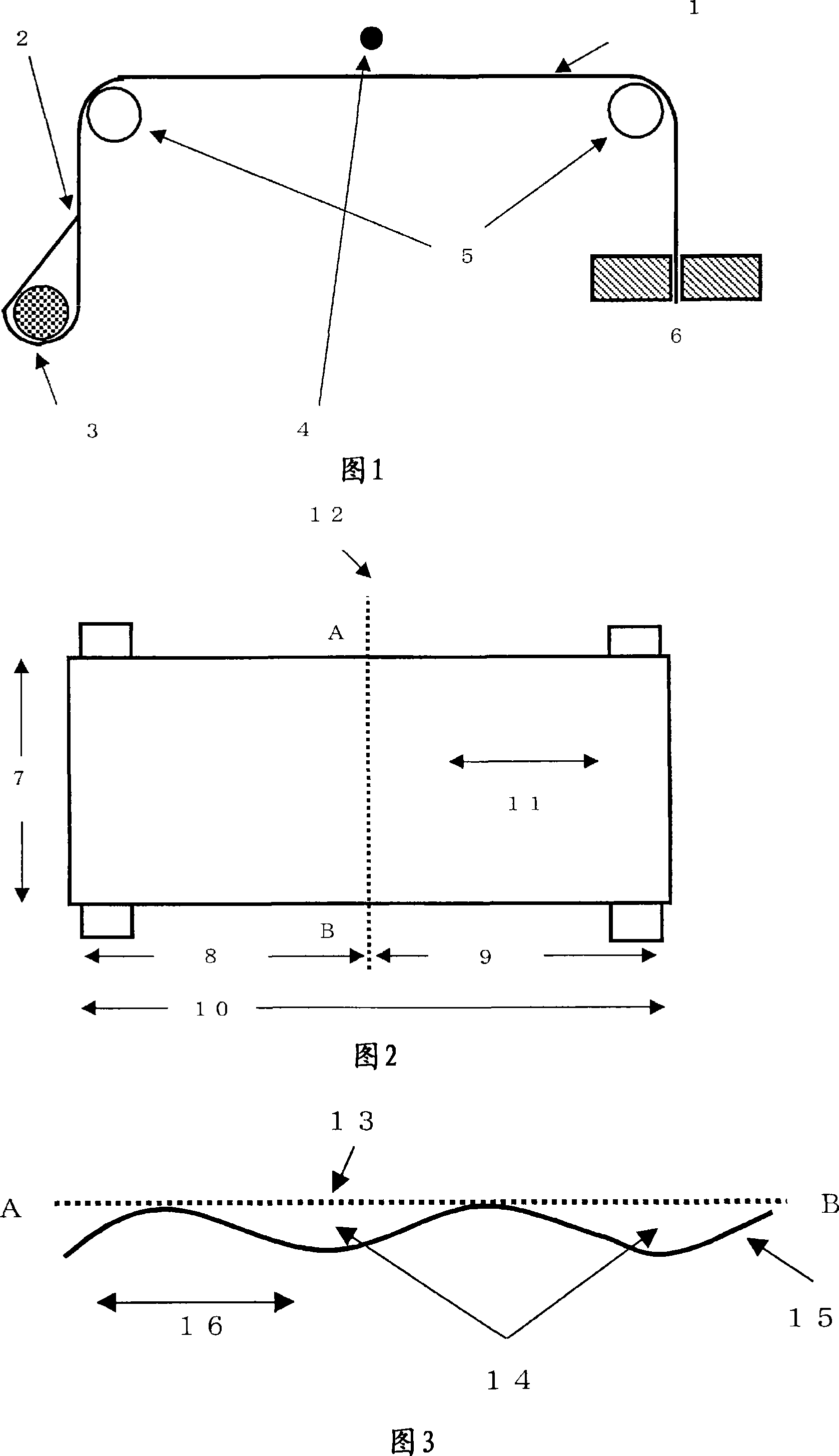

[0165] Hang the film on two support rolls installed at intervals of 3 m, fix one end, hang a load of 3 kg / m on the other end, and read the difference in slack between the width direction (TD) of the film and the horizontal base line generated at this time. In addition, in the measurement of the amount of slack, the line in contact with the highest position of the film in the TD direction as shown in FIG. 3 was defined as a horizontal base line. The amount of slack was measured at intervals of 50 mm from the end of the film, and the maximum value was read.

[0166] (Measurement of dynamic viscoelasticity)

[0167] Using D...

reference example 1

[0174] (Reference Example 1: Synthesis of Nylon Modified Epoxy Adhesive)

[0175] 50 parts by weight of polyamide resin (Platabond M1276 manufactured by Japan's Lilusan Corporation), 30 parts by weight of bisphenol A type epoxy resin (EPICO-TO 828 manufactured by Oil Chemical Shell Epoxy Corporation), cresol novolak type epoxy resin In the solution of 10 parts by weight, 150 parts by weight of toluene / isopropanol 1 / 1 mixed solution, mix 45 parts by weight of diaminodiphenyl sulfone / dicyandiamide 4 / 120% methyl cellosolve solution, and prepare the adhesive agent solution.

[0176] The adhesive was coated on a PET film with a thickness of 25 μm so as to be 11 μm after drying, and dried at 120° C. for 2 minutes to obtain a B-stage adhesive with a support.

[0177] (Determination of thermoplasticity).

[0178]A polyimide film composed of thermoplastic polyimide block components was produced at a maximum calcination temperature of 300°C and a calcination time of 15 minutes. It was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com