led chip and its growth method

A technology of LED chip and growth method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high leakage rate of LED chips and low product appearance yield, and achieve the improvement of appearance yield, leakage yield, and improvement The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

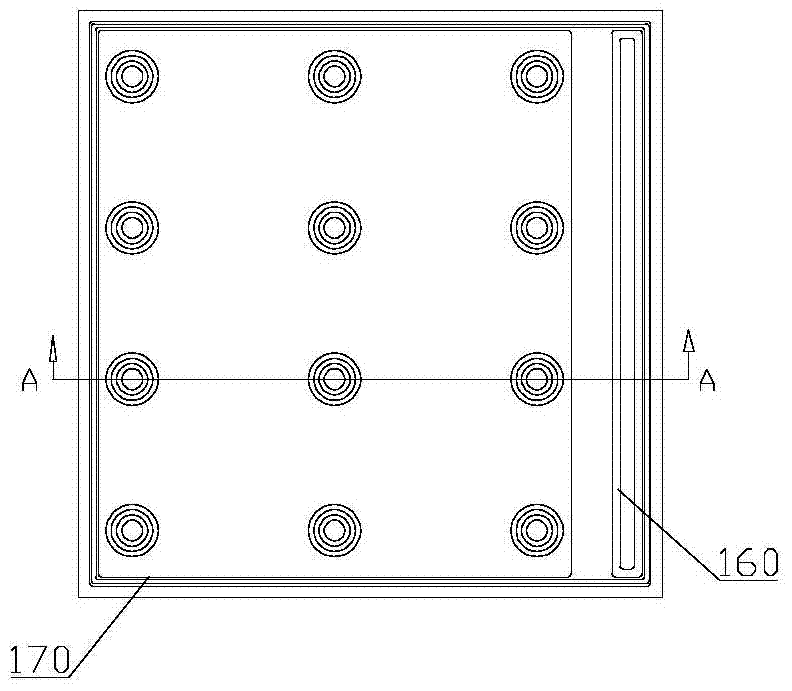

Image

Examples

Embodiment 1

[0062] 1. Thoroughly clean the epitaxial wafer, which is an epitaxial wafer with a GaN-based light-emitting diode chip structure grown on a PSS sapphire substrate;

[0063] 2. After cleaning, the ohmic contact layer is deposited by electron beam evaporation, wherein the material of the ohmic contact layer is indium tin oxide (ITO), and the coating rate is Thickness is

[0064] 3. Exposing the P-GaN through photolithography, wet etching and other steps. The etching solution is ITO etching solution, the temperature is 60-70°C, and the etching time is 4-5 minutes;

[0065] 4. Using steps such as inductive couple and plasma (ICP) etching, glue removal and cleaning, etc., to manufacture the mesa of the light-emitting area of a single core particle, exposing the N-type GaN layer 2 and the groove;

[0066] 5. Corrode the Wafer that has not been glued in step 4 as ITO to prevent leakage. The etching solution is ITO etching solution, the temperature is 60°C, and the etching tim...

Embodiment 2

[0077] 1. Thoroughly clean the epitaxial wafer, which is an epitaxial wafer with a GaN-based light-emitting diode chip structure grown on a PSS sapphire substrate;

[0078] 2. Using inductive couple and plasma (ICP) etching, glue removal and cleaning to manufacture the mesa of the light-emitting area of a single core particle, exposing the N-type GaN layer and groove;

[0079] 3. After cleaning, use electron beam evaporation to deposit a transparent conductive layer, wherein the material of the transparent conductive layer is indium tin oxide (ITO);

[0080] 4. Perform high-temperature annealing on Wafer to form a good ohmic contact between ITO and P-GaN, and at the same time, ITO is denser and has better conductivity. The annealing method is furnace tube annealing, the temperature is 500°C, and the time is 10 minutes;

[0081] 5. Make P-type electrodes and N-type electrodes by means of negative photolithography, sweeping, deposition, and stripping. The materials of P and N...

Embodiment 3

[0086] 1. Thoroughly clean the epitaxial wafer, which is an epitaxial wafer with a GaN-based light-emitting diode chip structure grown on a PSS sapphire substrate;

[0087] 2. After cleaning, the magnetron sputtering method (Sputter) is used to deposit the ohmic contact layer, wherein the material of the ohmic contact layer 100 is indium tin oxide (ITO), and the coating rate is Thickness is

[0088] 3. Exposing the P-GaN through photolithography, wet etching and other steps. The etching solution is ITO etching solution, the temperature is 70°C, and the etching time is 1 minute;

[0089] 4. Using steps such as inductive couple and plasma (ICP) etching, glue removal and cleaning, etc., to manufacture the mesa of the light-emitting area of a single core particle, exposing the N-type GaN layer 2 and the groove;

[0090] 5. Corrode the Wafer that has not been glued in step 4 as ITO to prevent leakage. The etching solution is ITO etching solution, the temperature is 60-70°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com