Clearance groove machining method and 3D substrate product

A processing method and technology for avoiding grooves, which are used in metal processing, manufacturing tools, glass production, etc., can solve problems such as poor tool marks, impact on product appearance yield, and difficulty in ensuring the accuracy of CNC tool locations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment provides a method for processing a 3D substrate product avoidance groove on a glass plate.

[0059] A method for processing an avoidance groove of a 3D substrate product, comprising the steps of:

[0060] (1) The 2D substrate is processed into a 2D intermediate by CNC.

[0061] (2) Bending the 2D intermediate to form a 3D intermediate.

[0062] (3) Carry out CNC machining and cutting of L-shaped avoidance grooves on the 3D intermediate body to form a 3D substrate product. Wherein, the avoidance groove processing method includes the following steps:

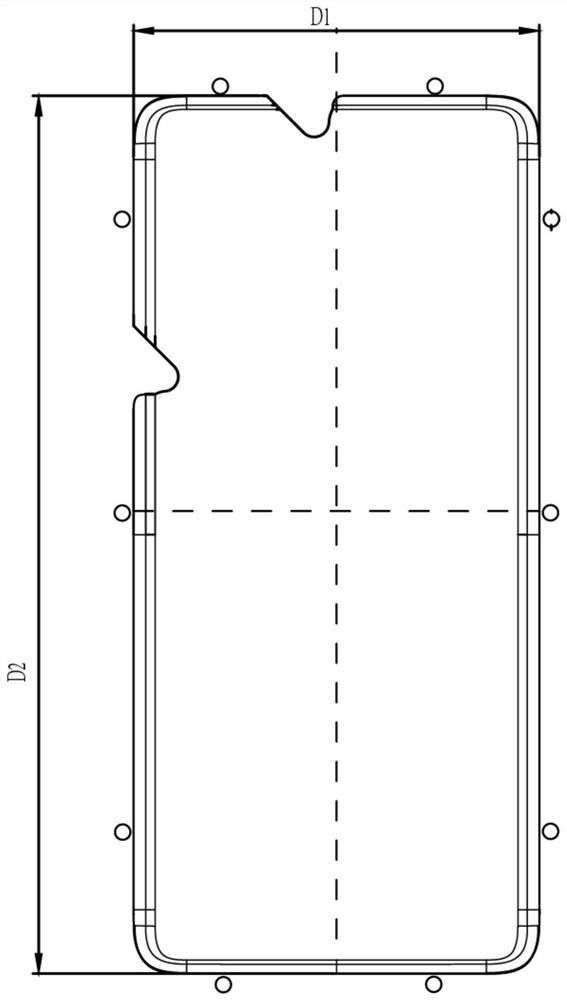

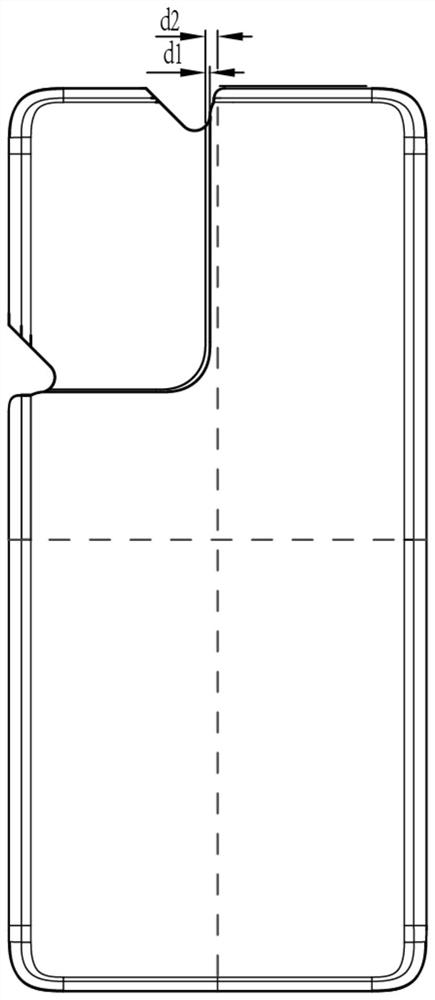

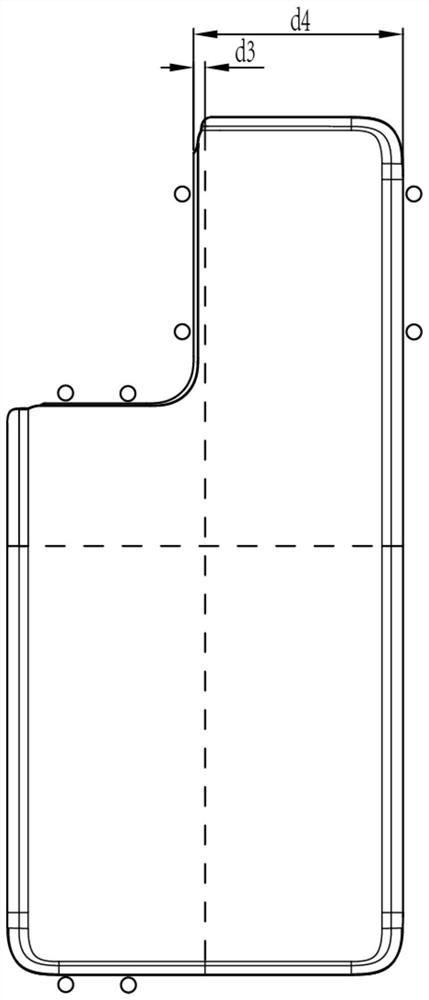

[0063] (a) detecting the width D1 of the short side and the length D2 of the long side of the product to be processed, fitting the center point and the centerline of the product to be processed according to the width D1 and the length D2, and fitting the CNC rough cutting curve according to d2, wherein , d2=d1+σ, d1 is the distance between the long side of the L-shaped relief groove and the center line, σ...

Embodiment 2

[0068] This embodiment provides a method for processing a 3D substrate product avoidance groove on a glass plate. Wherein, the width D1 of the 2D substrate is 80 mm, and the length D2 is 200 mm. The length of the long side of the L-shaped relief groove is 30mm, and the length of the short side of the L-shaped relief groove is 20mm.

[0069] A method for processing an avoidance groove of a 3D substrate product, comprising the steps of:

[0070] (1) The 2D substrate is processed into a 2D intermediate by CNC.

[0071] (2) Bending the 2D intermediate to form a 3D intermediate.

[0072] (3) Carry out CNC machining and cutting of L-shaped avoidance grooves on the 3D intermediate body to form a 3D substrate product. Wherein, the avoidance groove processing method includes the following steps:

[0073] (a) detecting the width D1 of the short side and the length D2 of the long side of the product to be processed, fitting the center point and the centerline of the product to be pro...

Embodiment 3

[0077] This embodiment provides a method for processing a 3D substrate product avoidance groove on a glass plate. Wherein, the width D1 of the 2D substrate is 80 mm, and the length D2 is 200 mm. The length of the long side of the L-shaped relief groove is 30mm, and the length of the short side of the L-shaped relief groove is 20mm.

[0078] A method for processing an avoidance groove of a 3D substrate product, comprising the steps of:

[0079] (1) The 2D substrate is processed into a 2D intermediate by CNC.

[0080] (2) Bending the 2D intermediate to form a 3D intermediate.

[0081] (3) Carry out CNC machining and cutting of L-shaped avoidance grooves on the 3D intermediate body to form a 3D substrate product. Wherein, the avoidance groove processing method includes the following steps:

[0082] (a) detecting the width D1 of the short side and the length D2 of the long side of the product to be processed, fitting the center point and the centerline of the product to be pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com