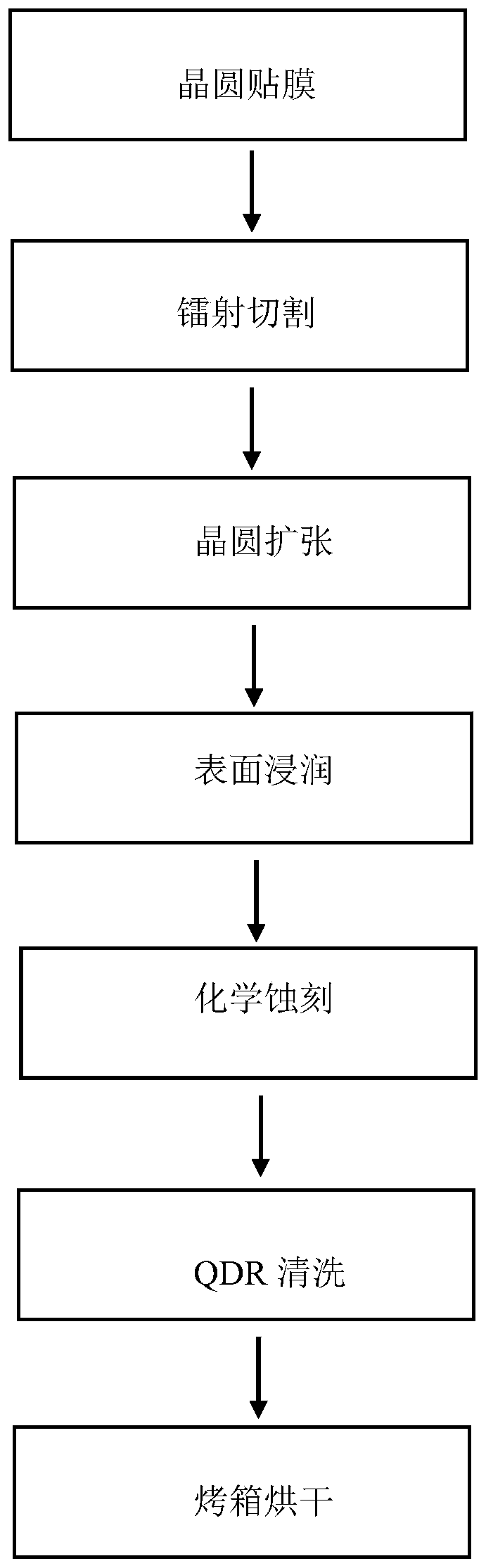

Processing method of chip after laser cutting

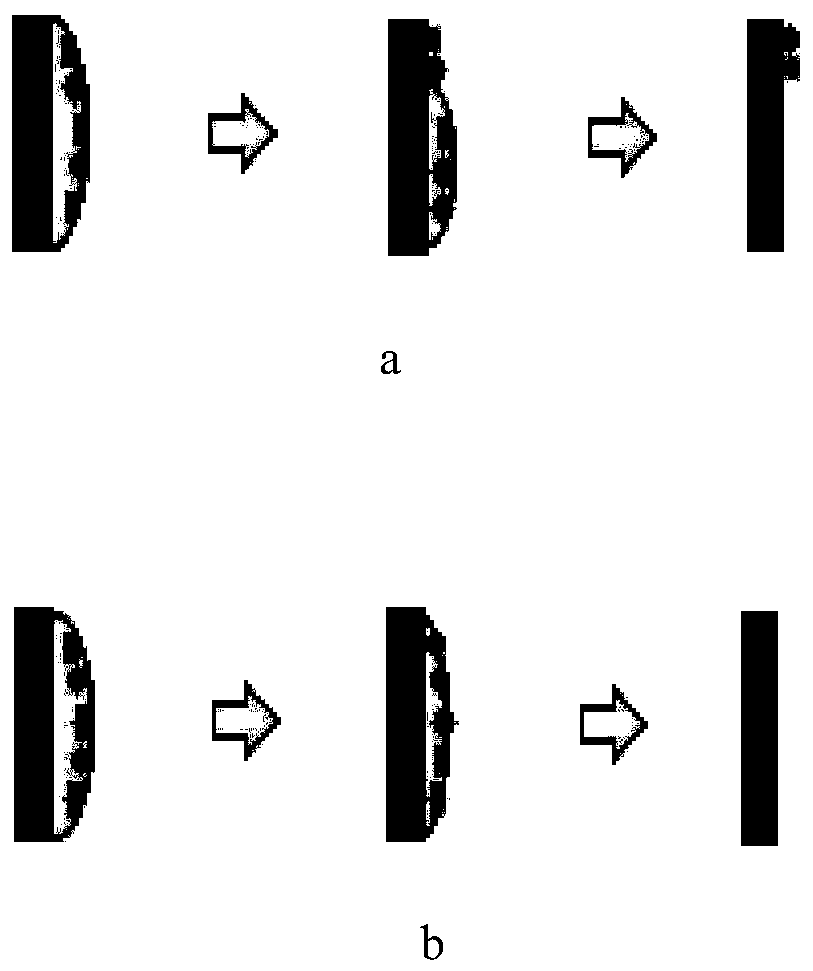

A processing method and chip technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as adhesion to the surface of chips, easy generation of crack fragments, delamination, and low utilization of chips, so as to achieve improvement in Chip surface, improve appearance yield, improve wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using the above method, a GaAs wafer with a thickness of 90um is cut with a 4W power UV laser, soaked in a surfactant solution for 100s after cutting, then soaked in an etching solution for 40s, and then transferred to a quick-discharge rinse tank and rinsed with DI water 10min, after cleaning, bake in a 55°C oven for 30min. Among them, the surfactant is: water 83.8%, polyethylene glycol 4.1%, polyethylene glycol octyl phenyl ether 3.2%; the etching solution is a mixed solution of ammonia water: hydrogen peroxide: water = 1:1:10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com