Hot bending protective film as well as preparation method and application thereof

A technology of protective film and hot bending, which is applied in the field of hot bending protective film and its preparation, can solve the problems of failure to achieve the visual effect of the appearance, the decline of the protective effect, and the failure to achieve the adhesion of the board, so as to improve the yield of the appearance surface, The effect of reducing spot defects and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

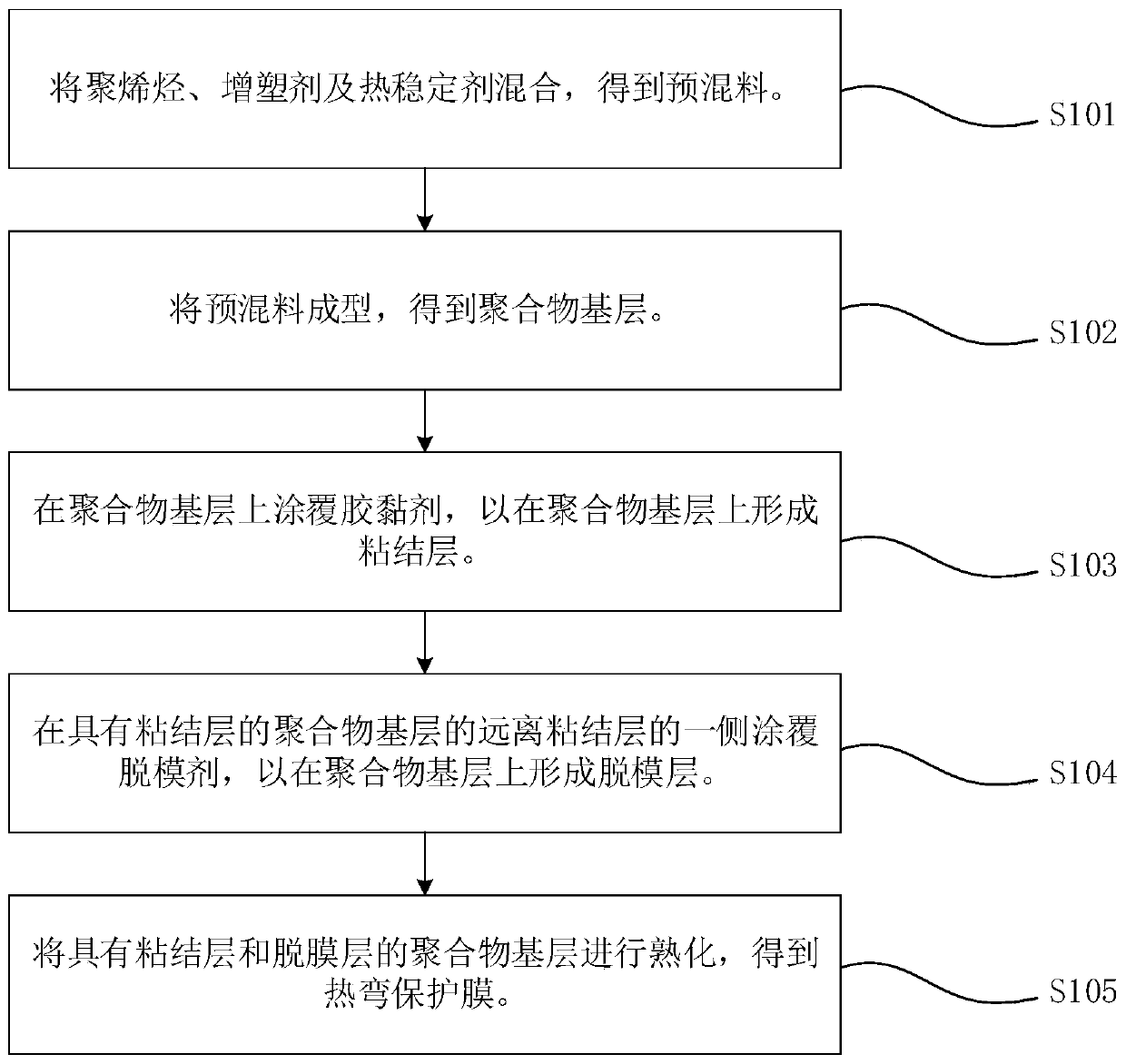

[0031] For the preparation method of the above-mentioned hot bending protective film 100 in one embodiment, refer to figure 2 , the method includes the following steps:

[0032] S101: mixing polyolefin, plasticizer and heat stabilizer to obtain a premix.

[0033] Wherein, the proportioning of polyolefin, plasticizer and thermal stabilizer is as mentioned above. In order to improve the uniformity of mixing the materials, the step of mixing the polyolefin, the plasticizer and the heat stabilizer is carried out under stirring conditions. Further, the stirring conditions may include: the rotation speed is 500r / min-1500r / min, and the time is 20min-40min.

[0034] S102: Molding the premix to obtain the polymer base layer 120 .

[0035] Wherein, the method for molding the premix may be a conventional molding method in the field, such as extrusion molding. Conditions for molding the premixed material may include: a temperature of 120° C. to 110° C. and a time of 20 minutes to 120...

Embodiment 1

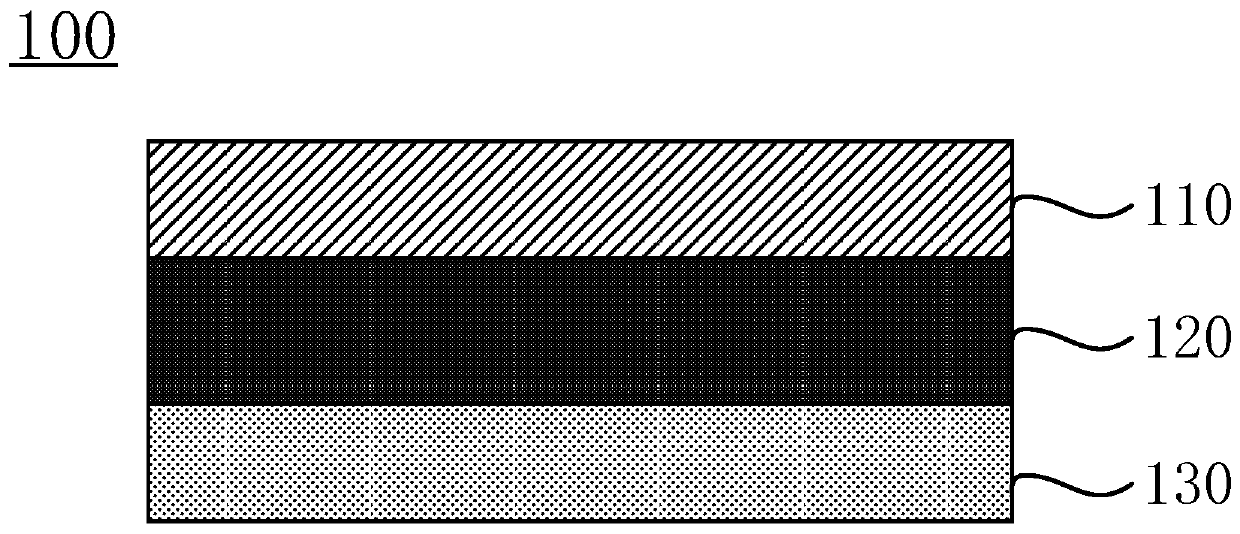

[0054] The structure of the heat bending protective film of the present embodiment is as follows: figure 1 shown.

[0055] Mix polyvinyl chloride, epoxidized soybean oil, and barium-zinc stabilizer in a weight ratio of 100:50:2, and stir at 800 r / min for 30 minutes to obtain a premix. The premix was placed in a twin-roll calender (manufactured by Chuanghong Instrument Equipment Co., Ltd., model CH-0201) and plasticized and extruded at 145 ° C for 30 minutes to obtain a polymer base layer with a thickness of 0.1 mm; Acrylate is evenly printed on one side of the polymer base layer by screen printing to form a bonding layer with a thickness of 10 μm, and then the fluorine-containing polyester varnish is evenly coated on the other side of the polymer base layer by screen printing , forming a release layer whose thickness is controlled to be 8 μm; place the compounded polymer base layer with an adhesive layer and a release layer in a curing chamber, and cure it at 60° C. for 36 ho...

Embodiment 2

[0057] The preparation process of the hot bending protective film of this embodiment is similar to that of Example 1, the difference is that the raw materials for preparing the polymer base layer are polyvinyl chloride, epoxy fatty acid methyl ester and barium zinc stabilizer, and the weight ratio is 100:25:6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com