Touch screen integrated with anti-peeping function and production process thereof

A touch screen, anti-peeping technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve the problems of high cost and large thickness, save manufacturing process and improve appearance yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

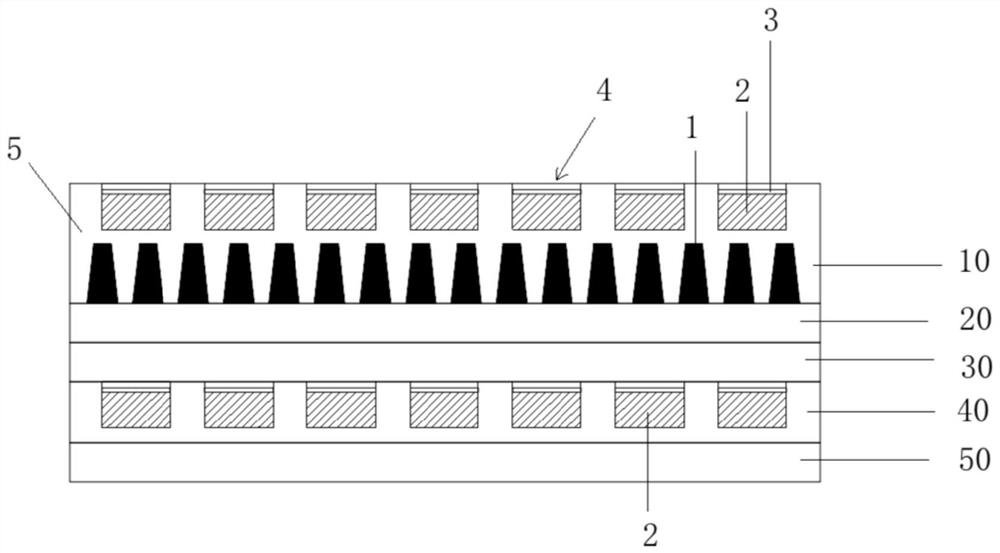

[0039] Such as figure 1 As shown, Embodiment 1 is an improvement on the prior art GMM structure touch screen, specifically including the upper line layer 10, the first substrate layer 20, the optical glue 30, and the lower line layer stacked in sequence from outside to inside. 40 . The second substrate layer 50 .

[0040] Both the upper line layer 10 and the lower line layer 40 include: an optical filling layer 5, a touch pattern 4, and a silver paste line 2; the touch pattern 4 is provided on the outside of the optical filling layer 5, and the touch pattern 4 is formed by a mold or other methods. In the depression formed on the optical filling layer 5 , the silver paste circuit 2 is filled in the touch pattern 4 , and a layer of black ink 3 is laid on the outside of the silver paste circuit 2 .

[0041] The wedge-shaped privacy-preventing structures 1 are densely arranged in the optical filling layer 5 of the upper line layer 10 , and the wedge-shaped privacy-preventing str...

Embodiment 2

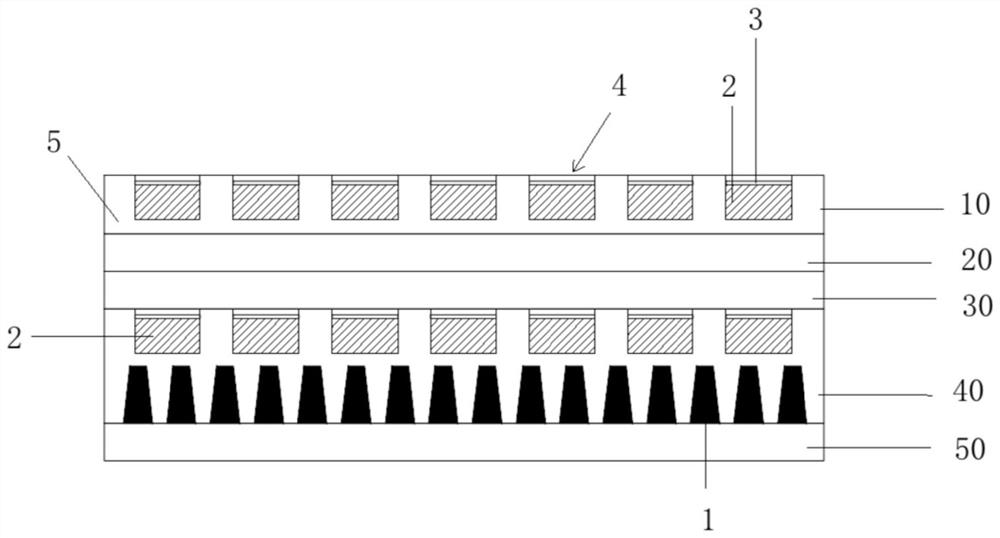

[0043] Such as figure 2 As shown, the difference from Embodiment 1 is that: the wedge-shaped privacy-preventing structure 1 is located in the optical filling layer 5 of the downline circuit layer 40 , and the wedge-shaped privacy-preventing structure 1 and the second substrate layer 50 form a privacy-preventing layer.

Embodiment 3

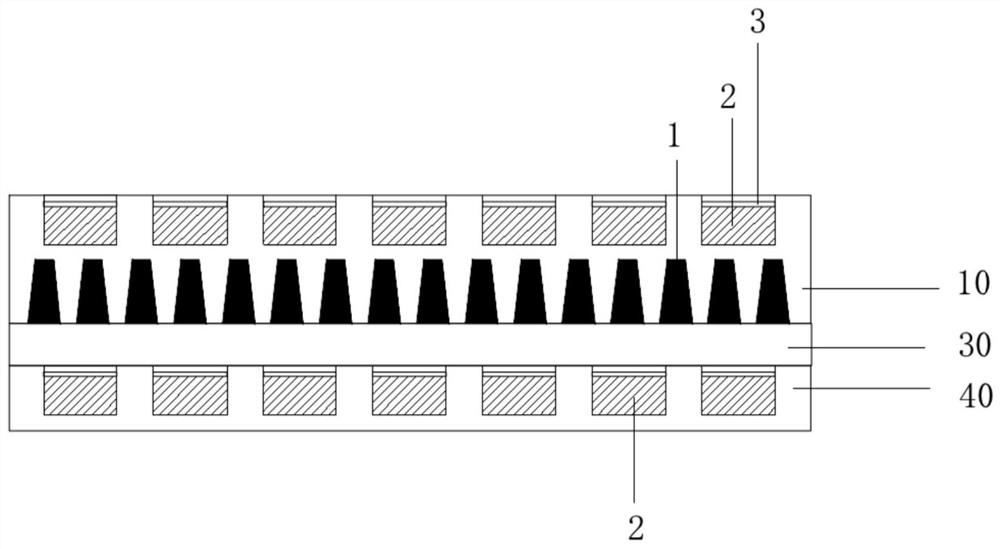

[0045] Such as image 3 As shown, the difference between the third embodiment and the first embodiment is that the first substrate layer 20 and the second substrate layer 50 are canceled in the third embodiment, and the upper circuit layer 10 and the lower circuit layer 40 are bonded by optical glue 30 Together, the plane where the wedge-shaped anti-peeping structure 1 is located serves as an anti-peeping layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com