Novel polyimide film and use thereof

A technology of polyimide film and polyamic acid, which is applied in the direction of heat activated film/sheet, film/sheet adhesive, synthetic resin layered products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

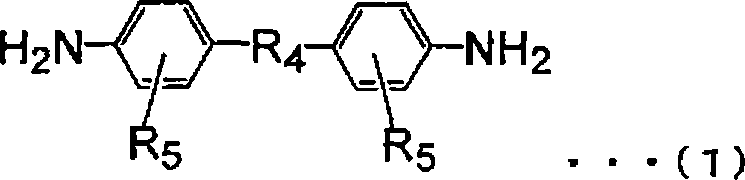

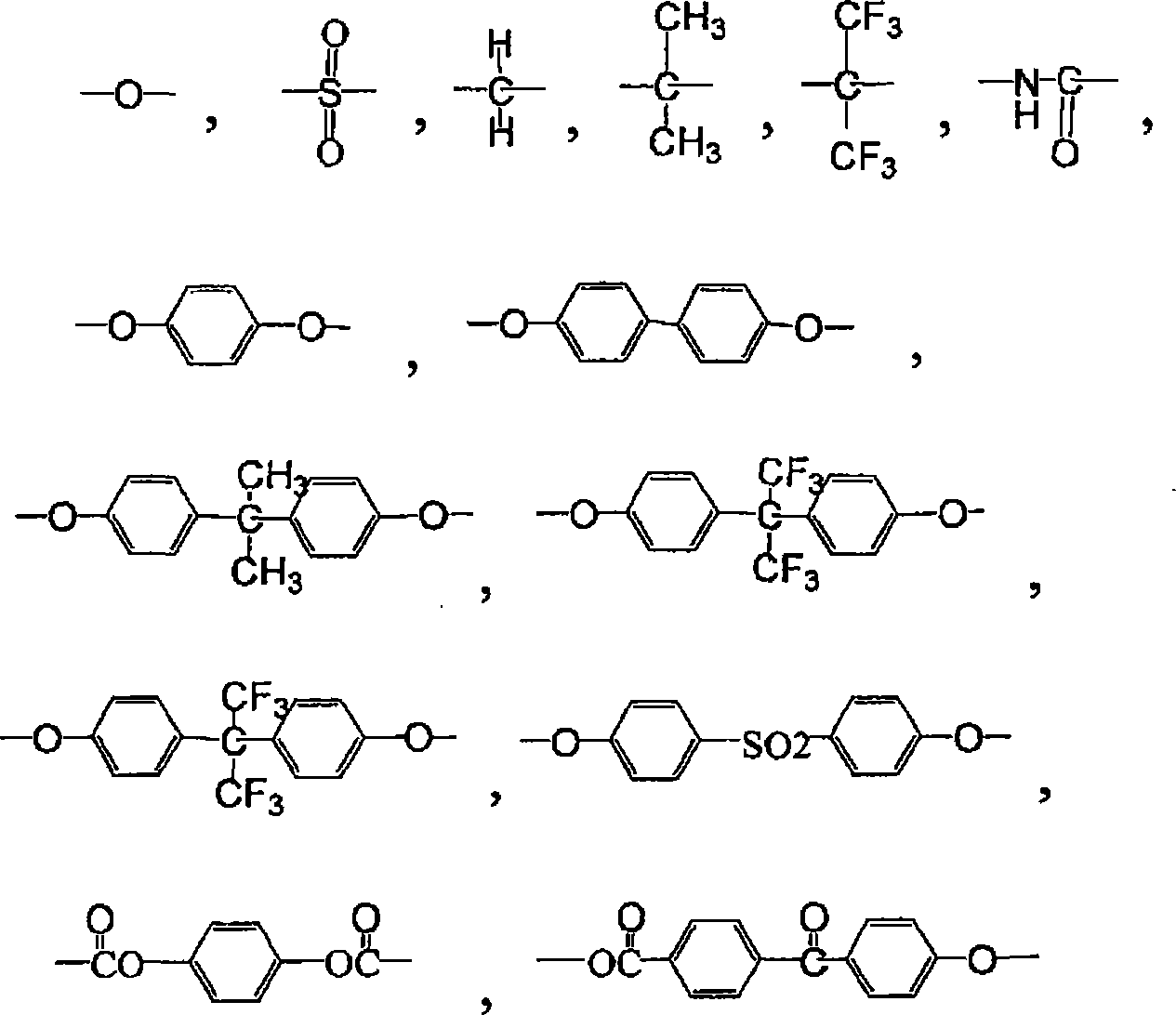

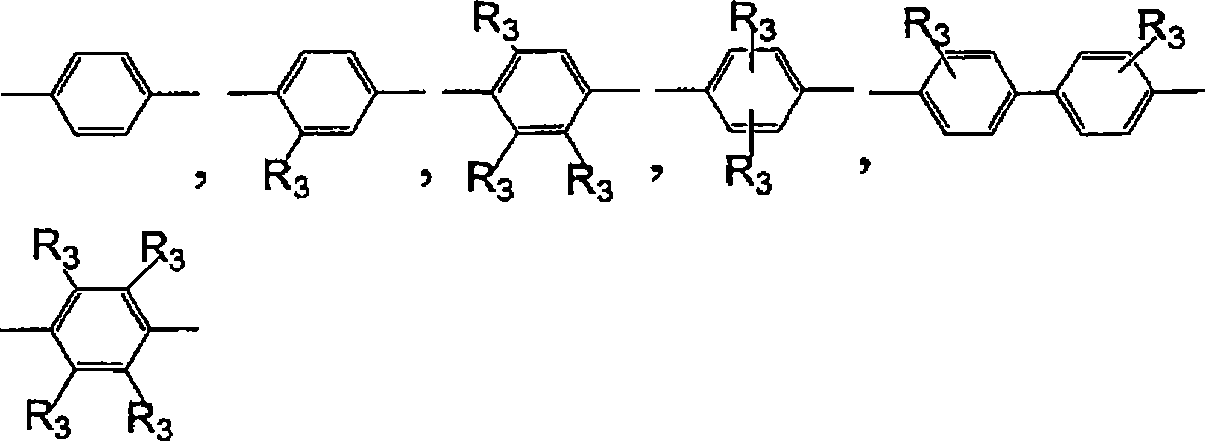

Method used

Image

Examples

Embodiment

[0209] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited to these examples. Various alterations, modifications and changes may be made by those skilled in the art without departing from the scope of the present invention. It should be noted that the glass transition temperature of thermoplastic polyimide, storage modulus, tensile modulus, hygroscopic expansion coefficient and linear expansion coefficient of polyimide film in Synthetic Examples, Examples and Comparative Examples , The dimensional change rate of the flexible metal foil-clad laminate, the metal foil peel strength, and the evaluation methods of the moisture absorption welding resistance are as follows.

[0210] [Glass transition temperature]

[0211] The glass transition temperature was measured using DMS6100 manufactured by SII Nano Technology, and the inflection point of the storage elastic modulus was used as the glass transition temp...

Synthetic example 1

[0247] [Synthesis Example 1: Synthesis of Thermoplastic Polyimide Precursor]

[0248] Add 780 g of N,N-dimethylformamide (hereinafter also referred to as "DMF") and 115.6 g of BAPP to a glass flask with a capacity of 2000 ml, and slowly add 3, 3', 4, 4 78.7 g of '- biphenyl tetracarboxylic dianhydride (it may be called "BPDA" hereafter). Next, 3.8 g of 3,3', 4,4'- ethylene glycol dibenzoate tetracarboxylic dianhydride (it is also called "TMEG" hereafter) was added, and it stirred under ice bath for 30 minutes. Separately, a solution in which 2.0 g of TMEG was dissolved in 20 g of DMF was prepared, and this solution was gradually added to the above-mentioned reaction solution and stirred while paying attention to the viscosity. When the viscosity reached 3000 poise (300 Pa.s), the addition and stirring were stopped to obtain a polyamic acid solution.

[0249] The obtained polyamic acid solution was poured onto a 25 μm PET film (Cerapeel HP, product of TOYO Metallizing Co., Lt...

Embodiment 1~4

[0250] [Examples 1-4: Synthesis of polyimide film]

[0251] With the inside of the reaction system kept at 5°C, 4,4'-diaminodiphenyl ether (hereinafter also referred to as "4,4'-ODA") and BAPP, for stirring. After visually confirming the dissolution, 3,3',4,4'-benzophenonetetracarboxylic dianhydride (hereinafter also referred to as "BTDA") was added at the molar ratio shown in Table 1, and stirred for 30 minutes.

[0252] [Table 1]

[0253]

4.4'-ODA

BAPP

BTDA

PMDA

(1st)

p-PDA

PMDA

(2nd)

Example 1

20

30

25

20

50

52

Example 2

20

30

30

15

50

52

Example 3

10

40

20

25

50

52

Example 4

10

40

25

20

50

52

[0254] Next, pyromellitic dianhydride (hereinafter also referred to as P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com