Fuel battery pile

A fuel cell stack and electrolyte technology, applied to fuel cell components, solid electrolyte fuel cells, battery pack components, etc., can solve problems such as poor supply of oxidant gas, decline in fuel cell output performance, and blockage of connecting flow paths. Achieve simple structure, prevent clogging, and suppress dimensional changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

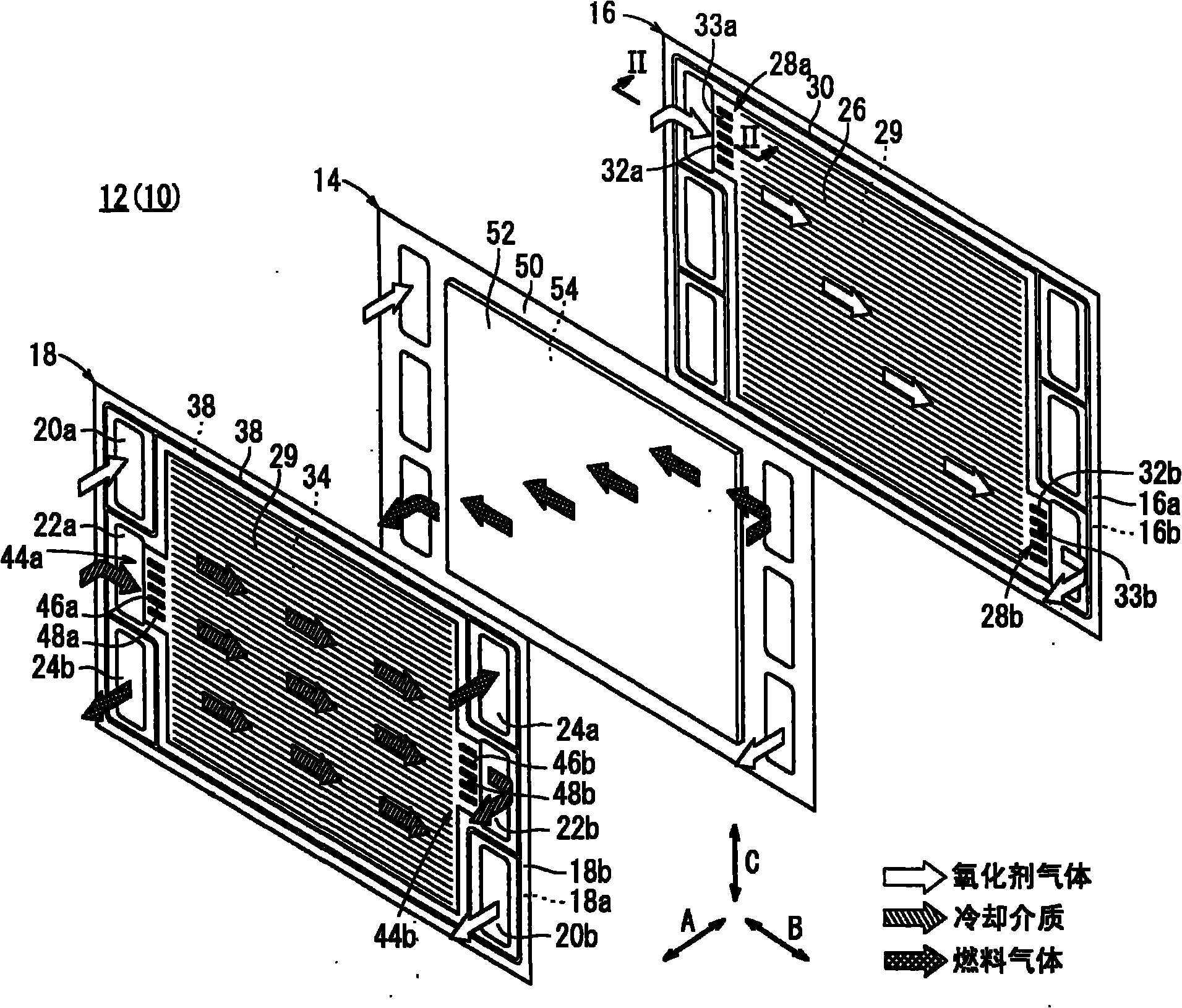

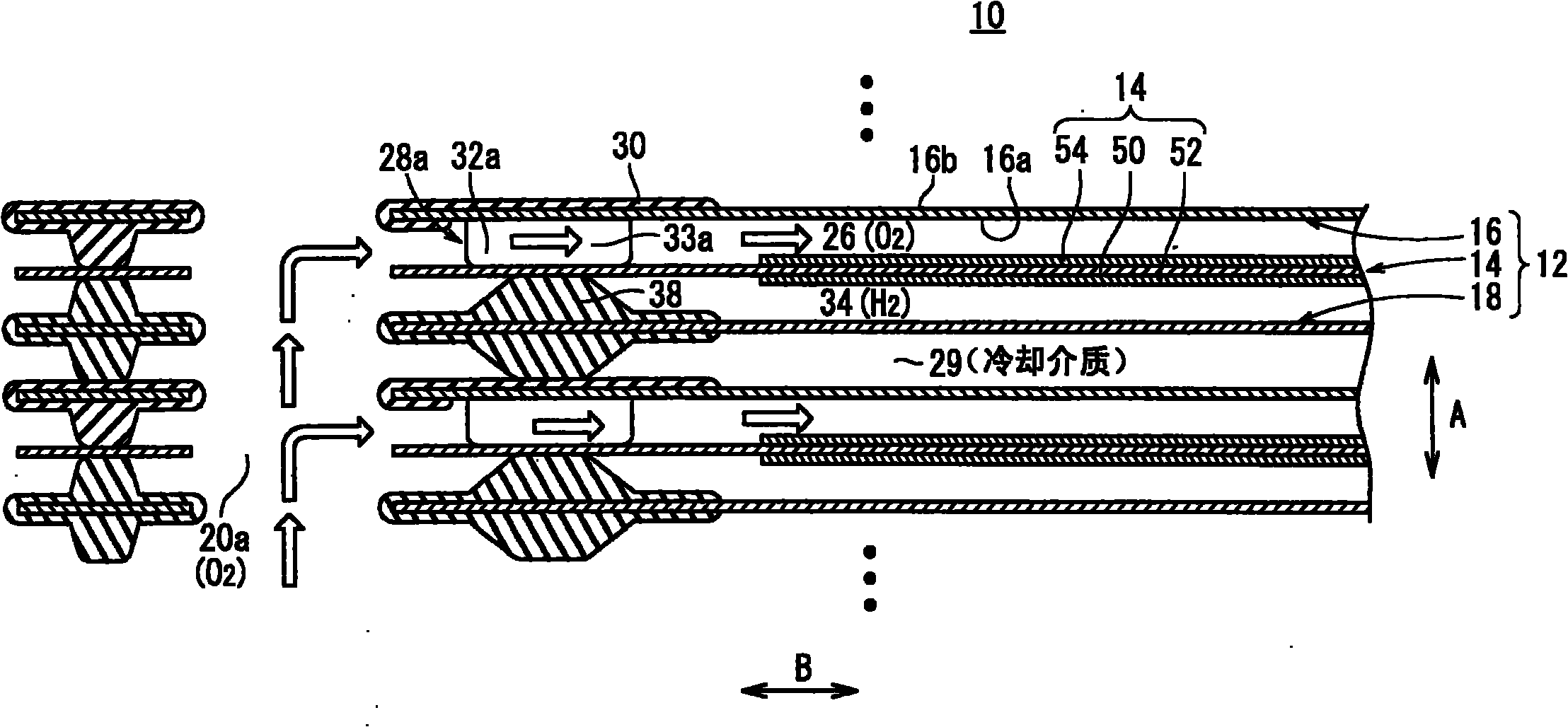

[0058] Such as figure 1 and figure 2 As shown, the fuel cell stack 10 according to the first embodiment of the present invention is formed by stacking a plurality of fuel cells 12 in the horizontal direction (direction of arrow A) or vertical direction (direction of arrow C).

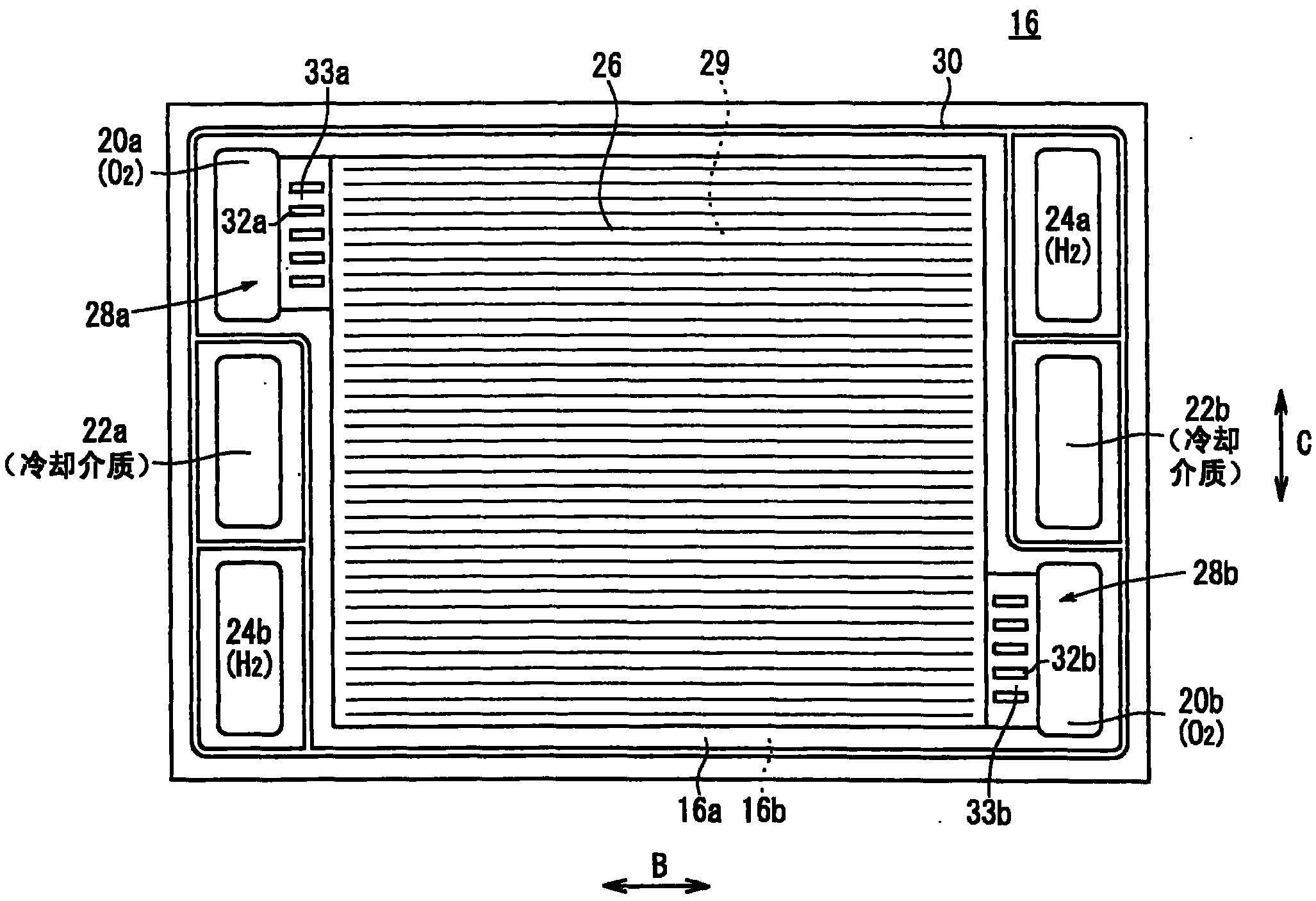

[0059] In the fuel cell 12 , an electrolyte membrane-electrode structure (electrolyte-electrode structure) 14 is sandwiched between first metal separators 16 and second metal separators 18 . The first metal separator 16 and the second metal separator 18 are made of, for example, a steel plate, a stainless steel plate, an aluminum plate, or a plated steel plate, and are punched into a corrugated plate shape to form a flow path described later.

[0060] Such as figure 1 As shown, in the arrow B direction of the fuel cell 12 ( figure 1 , in the horizontal direction) along the arrow C direction (vertical direction) along the arrow C direction (vertical direction) arranged in a stacking direction, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com