Preparation of foam aluminum alloy base wave-absorbing material

A foamed aluminum alloy and wave absorbing material technology is applied in the field of material science to achieve the effects of optimizing wave absorbing properties, improving wave absorbing properties and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

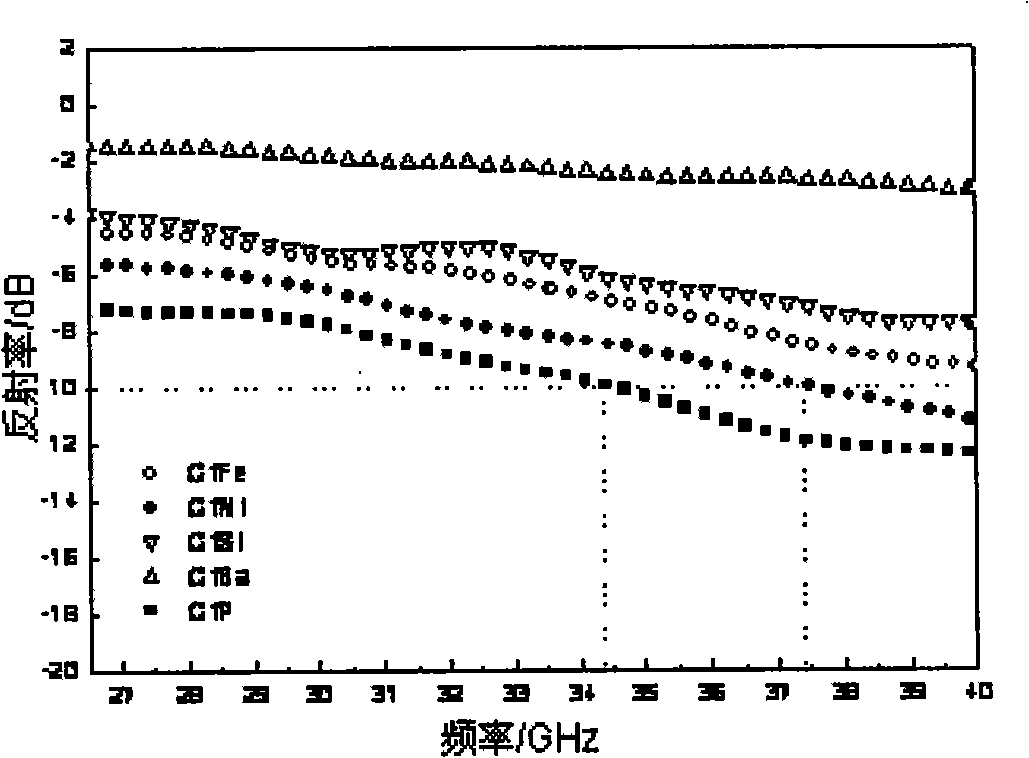

Embodiment 1

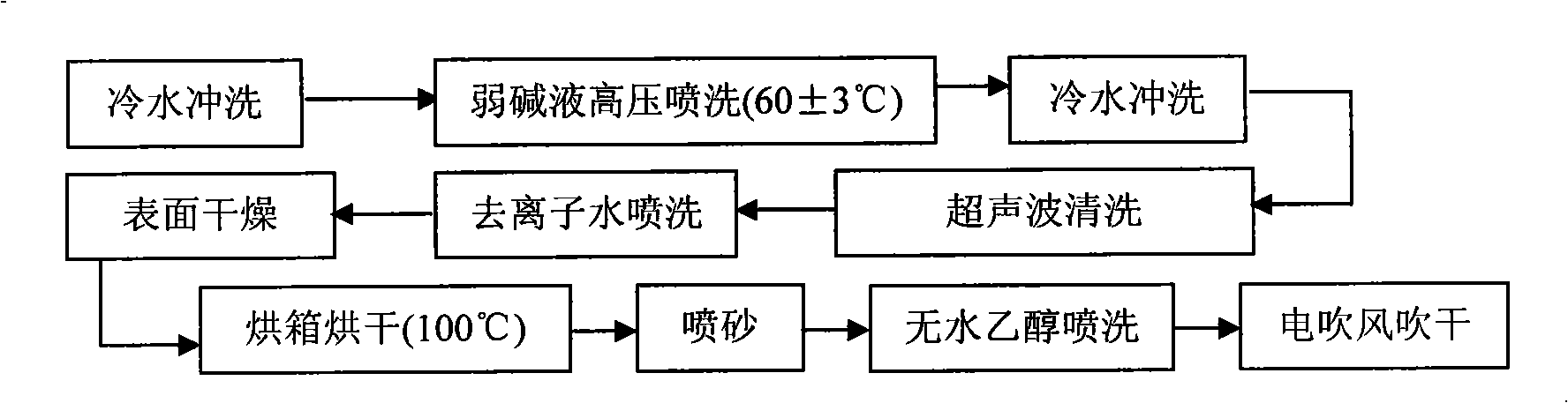

[0050] The foamed aluminum alloy with an appearance size of 80mm×80mm, a relative density of 0.148-0.185, and an average pore diameter of 6-7mm is used as the substrate, and the foamed aluminum alloy substrate is washed with room temperature cold water to remove some mechanical debris remaining on the surface and in the pores. Then use a JD-2025B air compressor to spray lye to clean the surface of the foamed aluminum alloy substrate under the condition of a spray pressure of 0.8Mpa. The temperature of the lye is controlled at 60±3°C to prevent the surface of the foamed aluminum alloy substrate from being corroded. ; Immediately rinse with cold water at room temperature after spraying the lye, and then clean it with a KQ-100 ultrasonic cleaner for 15 minutes, using a frequency of 40KHz; then spray the surface with deionized water to remove residual lye; use a hair dryer to shorten the drying time of the surface to avoid The hanging drops of water will erode the surface due to co...

Embodiment 2

[0060] The foamed aluminum alloy with an appearance size of 80 mm × 80 mm, a relative density of 0.148 to 0.185, and an average pore diameter of 6 to 7 mm is used as the substrate, and the surface pretreatment method of the foamed aluminum alloy substrate is the same as in Example 1.

[0061] Take 20g of silicon carbide wave absorbing agent as the filler for wave absorbing paint, add titanate coupling agent JN-108 into the silicon carbide wave absorbing agent, the amount of coupling agent JN-108 is 0.6g, and then add 5ml of diluent, The diluent is a mixture of n-butanol: xylene: propylene glycol methyl ether = 6:4:1, and it is stirred at a speed of 10000 r / min for 30 minutes in a high-shear force dispersing emulsifier.

[0062] Dilute 0.4g of dispersant CH-13F with 5ml of diluent (mixture of n-butanol: xylene: propylene glycol methyl ether = 6:4:1), and pour it into the pretreated wave absorbing agent filler in a glass mortar Mix and grind in medium to complete the dispersion ...

Embodiment 3

[0069] The foamed aluminum alloy with an appearance size of 80 mm × 80 mm, a relative density of 0.148 to 0.185, and an average pore diameter of 6 to 7 mm is used as the substrate, and the surface pretreatment method of the foamed aluminum alloy substrate is the same as in Example 1.

[0070] Take 20g of barium titanate wave absorbing agent as the filler for wave absorbing paint, add titanate coupling agent JN-198 into the barium titanate wave absorbing agent, the amount of coupling agent JN-198 is 0.6g, and then add 5ml of diluted The diluent is a mixed solution of n-butanol:xylene:propylene glycol methyl ether=6:4:1, which is stirred for 30min at a speed of 10000r / min in a high-shear force dispersing emulsifier.

[0071] Dilute 0.4g of dispersant CH-13 with 5ml of diluent (mixture of n-butanol: xylene: propylene glycol methyl ether = 6:4:1), pour it into the pretreated wave-absorbing agent filler in a glass mortar Mix and grind in medium to complete the dispersion of wave ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com