Graphene/nano ferrite based water electromagnetic shielding paint and preparation method thereof

A technology of electromagnetic shielding coating and nano-ferrite, which is applied in conductive coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor shielding efficiency of electromagnetic shielding coatings, achieve excellent wave-absorbing performance, and improve absorption Wave performance, overcome the effect of cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The formulation of the water-based electromagnetic shielding coating is:

[0017] Electromagnetic shielding filler: 10%

[0018] Water-based acrylate: 70%

[0019] Purified water: 16%

[0020] Sodium Lauryl Sulfonate: 3%

[0021] Coalescing agent lauryl alcohol: 1%

[0022] Electromagnetic shielding filler preparation: accurately weigh 0.27gFeCl according to stoichiometry 3 ·6H 2 O (1mmol), 0.18gCoCl 2 ·6H 2 O (0.5 mmol) was dissolved in 30 mL of water to prepare a solution, added to 2 mL of 15 mg / mL graphene oxide dispersion, and ultrasonicated for 30 minutes. Use sodium hydroxide solution (5M) to adjust the pH to 11, and finally add the reducing agent Na 2 S 2 o 3 ·5H 2 O, put into a reaction kettle, seal it, place it in an oven, and react at 150°C for 15 hours. After washing and centrifuging, the graphene / nano-cobalt ferrite composite material is obtained directly. figure 1 It is a transmission electron microscope (HitachiHT7700) photo of the synthetic m...

Embodiment 2

[0025] The formulation of the water-based electromagnetic shielding coating is:

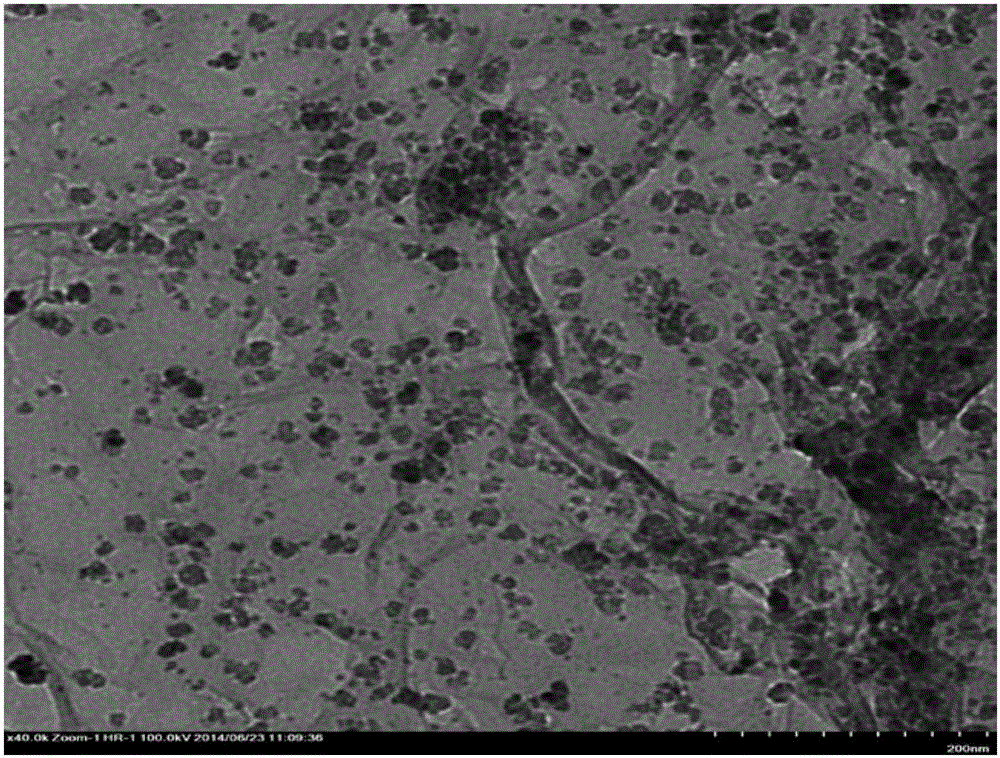

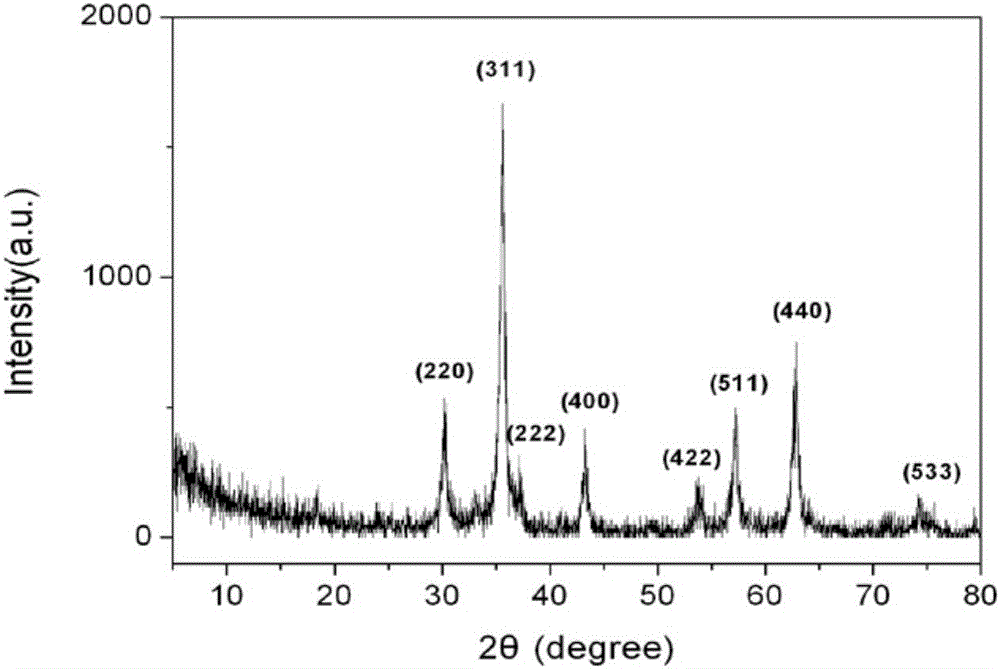

[0026] Electromagnetic shielding filler: 10%

[0027] Water-based polyurethane: 68%

[0028] Purified water: 16%

[0029] Sodium Lauryl Sulfate: 5%

[0030] Coalescing agent lauryl alcohol ester: 1%

[0031] Electromagnetic shielding filler preparation: accurately weigh 0.48gZn(NO 3 ) 2 ·6H 2O(1.6mmol) and 1.31gFe(NO 3 ) 3 9H 2 O (3.2 mmol) was dissolved in 30 mL of water to prepare a solution, added to 2 mL of 20 mg / mL graphene oxide dispersion, and ultrasonicated for 30 minutes. Use sodium hydroxide solution (5M) to adjust the pH to 11, and finally add the reducing agent Na 2 S 2 o 3 ·5H 2 O, put into a reaction kettle, seal it, place it in an oven, and react at 150°C for 15 hours. After washing and centrifuging, the graphene / nano-copper ferrite composite material is obtained directly.

[0032] Preparation of water-based polyurethane electromagnetic shielding coating: add the pre...

Embodiment 3

[0034] The formulation of the water-based electromagnetic shielding coating is:

[0035] Electromagnetic shielding filler: 20%

[0036] Water-based epoxy resin: 60%

[0037] Purified water: 16%

[0038] OP-10: 3%

[0039] Coalescent Dipropylene Glycol Monobutyl Ether: 1%

[0040] Electromagnetic shielding filler preparation: accurately weigh 0.27gFeCl according to stoichiometry 3 ·6H 2 O (1mmol), 0.06gNiCl 2 ·6H 2 O (0.25mmol), 0.09gCoCl 2 ·6H 2 O (0.25 mmol) was dissolved in 30 mL of water to prepare a solution, added to 2 mL of 15 mg / mL graphene oxide dispersion, and ultrasonicated for 30 minutes. Use sodium hydroxide solution (5M) to adjust the pH to 11, and finally add the reducing agent Na 2 S 2 o 3 ·5H 2 O, put into a reaction kettle, seal it, put it in an oven, and react at 150°C for 24 hours. After washing and centrifuging, the graphene / nano-cobalt-nickel ferrite composite material is obtained directly.

[0041] Preparation of water-based epoxy resin ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shielding effectiveness | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com