Water-based nano heat insulating coating used for glass and preparation method thereof

A technology of heat-insulating nano-coatings and nano-coatings, which is applied to radiation-absorbing coatings, polyurea/polyurethane coatings, coatings, etc., and can solve problems such as poor stability of nano-ATO coatings, and contradictions in coating transparency and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0037] Preparation of nano-ATO slurry:

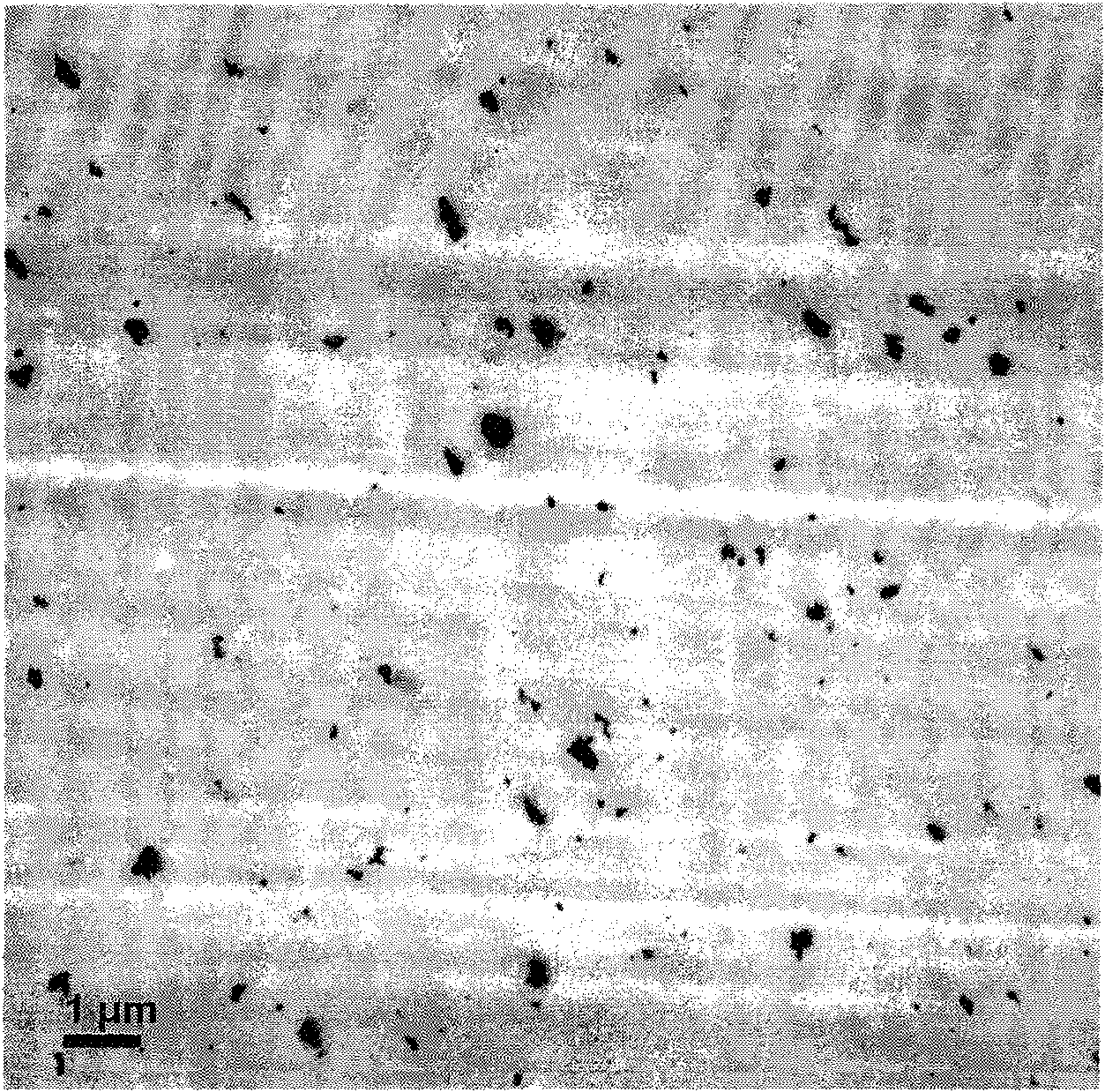

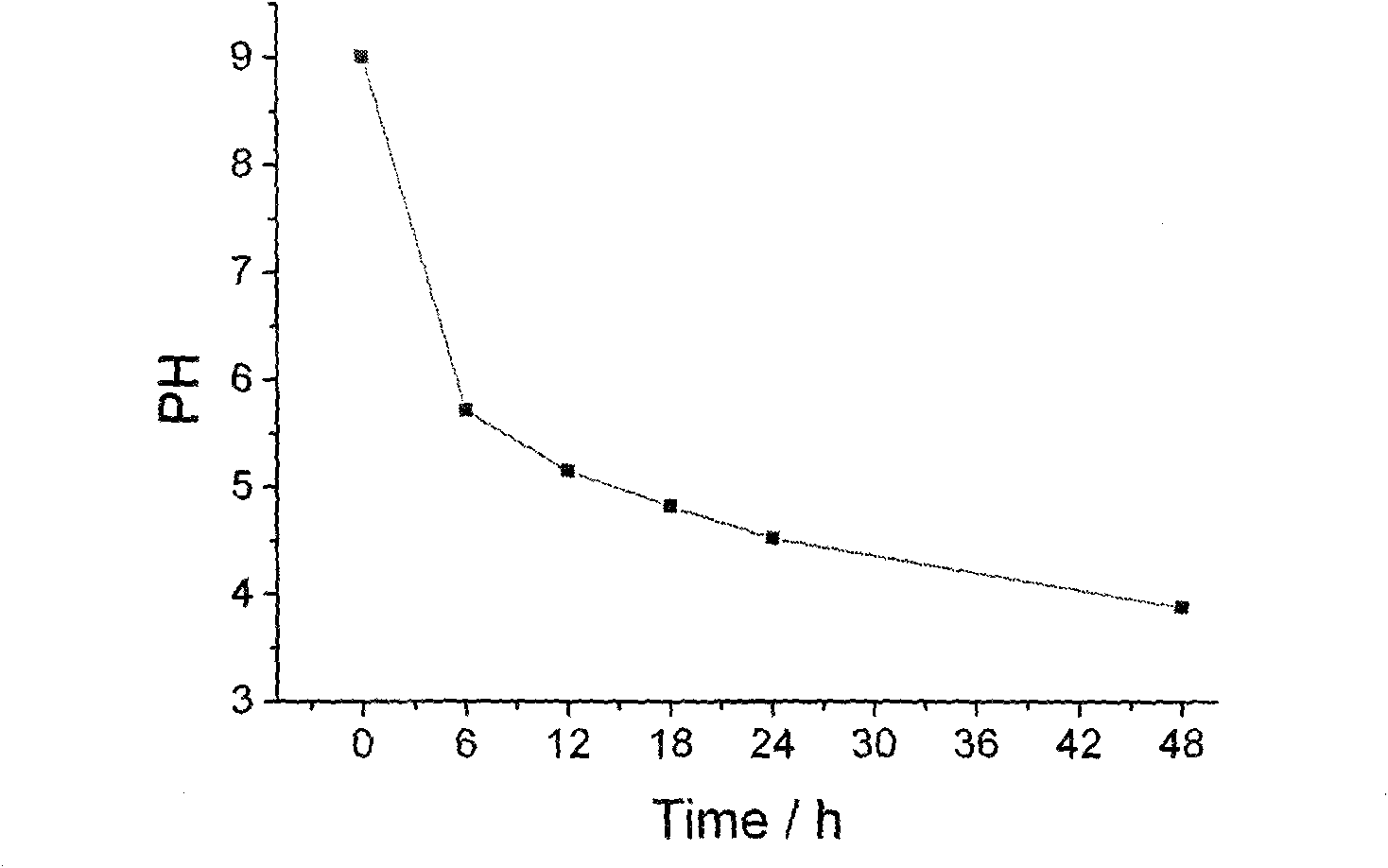

[0038] Add powdered ATO and dispersant KH570 to water, and make nano-ATO slurry by ball milling at 3000r / min for 48 hours. Keep the system temperature at about 30°C, and then adjust the pH value of the system to 8. The effect of ball milling time on the pH value of the slurry system Such as figure 2 shown. The laser particle size analyzer is used to test the dispersed particle size and distribution of the slurry, the morphology of the particles is characterized by TEM, the stability of the slurry is studied by the centrifugal sedimentation method, and the thermal weight loss and infrared spectroscopy are used to prove whether KH570 has been bonded.

[0039] Preparation of matrix resin:

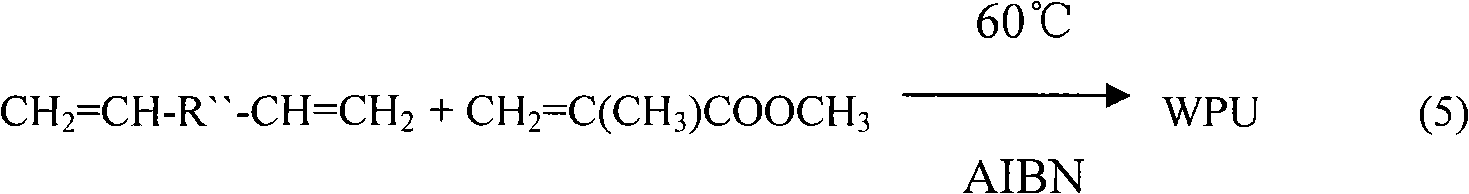

[0040]WPU can be synthesized according to the following steps: Add polyester diol (Mn1000) and DMPA (where -COOH accounts for about 1.5% of the molecular chain mass ratio) into a three-necked bottle, vacuum dehydrate at 120-130°C for 2 hours, and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com