Graphene oxide-ceramic hybrid coating layer, and method for preparing the same

A technology of graphene and ceramics, applied in coatings, heat-sensitive coatings, devices for coating liquids on surfaces, etc., can solve problems such as property degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

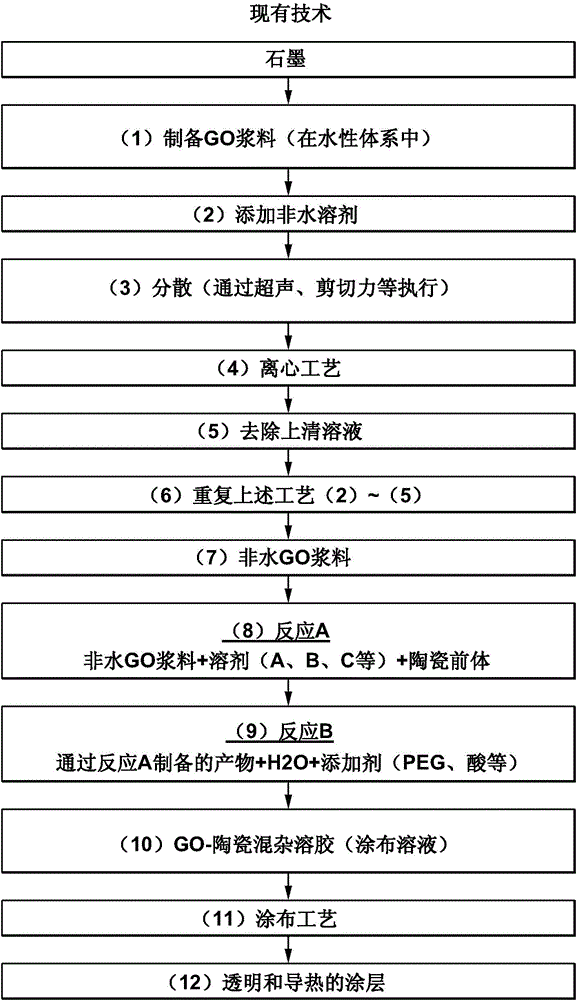

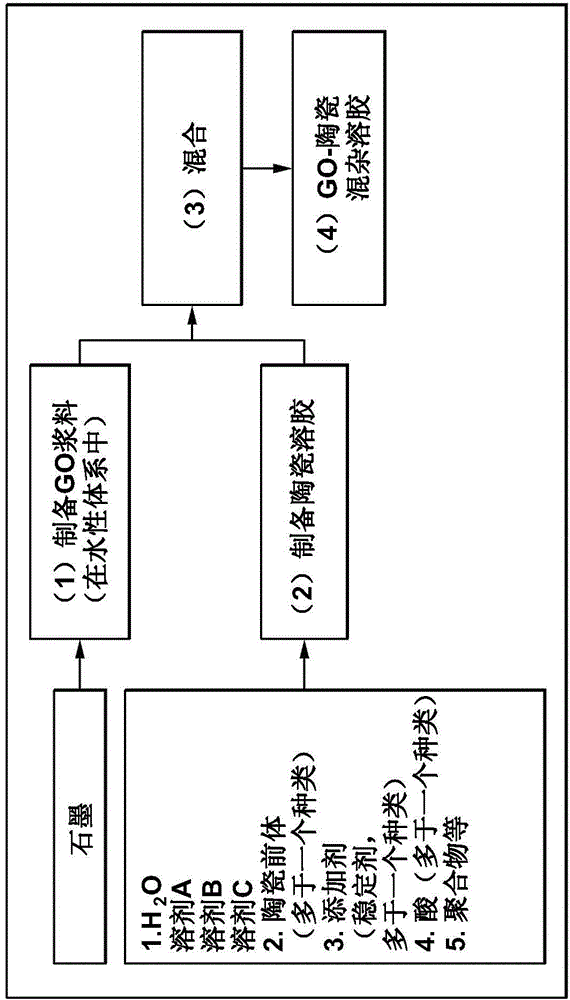

[0041] According to another exemplary embodiment, the method for preparing a graphene oxide-ceramic hybrid coating may include: preparing a solution including graphene oxide slurry replaced by a first non-aqueous solvent; mixing the solution with a second non-aqueous solvent A water-based solvent and a ceramic precursor are combined to prepare a mixture; a dispersant and water are added to the mixture to prepare a graphene oxide-ceramic hybrid sol solution; and a substrate is coated with the graphene oxide-ceramic hybrid sol solution.

[0042] The preparation of the solution including the graphene oxide slurry replaced by the first non-aqueous solvent may be the first process of preparing the graphene oxide-ceramic hybrid coating to replace the aqueous environment of the graphene oxide slurry with a non-aqueous environment. Specifically, the process may include performing mechanical dispersion treatment and centrifugation after mixing the graphene oxide aqueous slurry with the ...

preparation example 1

[0054] (Preparation of water-based GO slurry)

[0055] 10 g of natural graphite and 7.5 g of sodium nitrate were placed in the reactor and 621 g of 96% sulfuric acid was slowly added while stirring. After the three materials were well mixed, 45g of manganese peroxide was added. Since manganese peroxide has an explosion risk and generates heat and gas when reacting with strong sulfuric acid, manganese peroxide was added slowly over about 1 hour. After adding manganese peroxide, the resultant was stirred and reacted at room temperature for about 4 to 6 days. Then, 1 L of 5% sulfuric acid solution was added. The reactor was properly cooled and sulfuric acid was added slowly over 1 hour due to the large amount of heat and gas that could be generated. Furthermore, the resultant was left to stand at room temperature for one day while stirring. After one day, slowly add 30g30% hydrogen peroxide and react for 2 hours. To remove a large amount of sulfuric acid and hydrogen peroxid...

preparation example 2

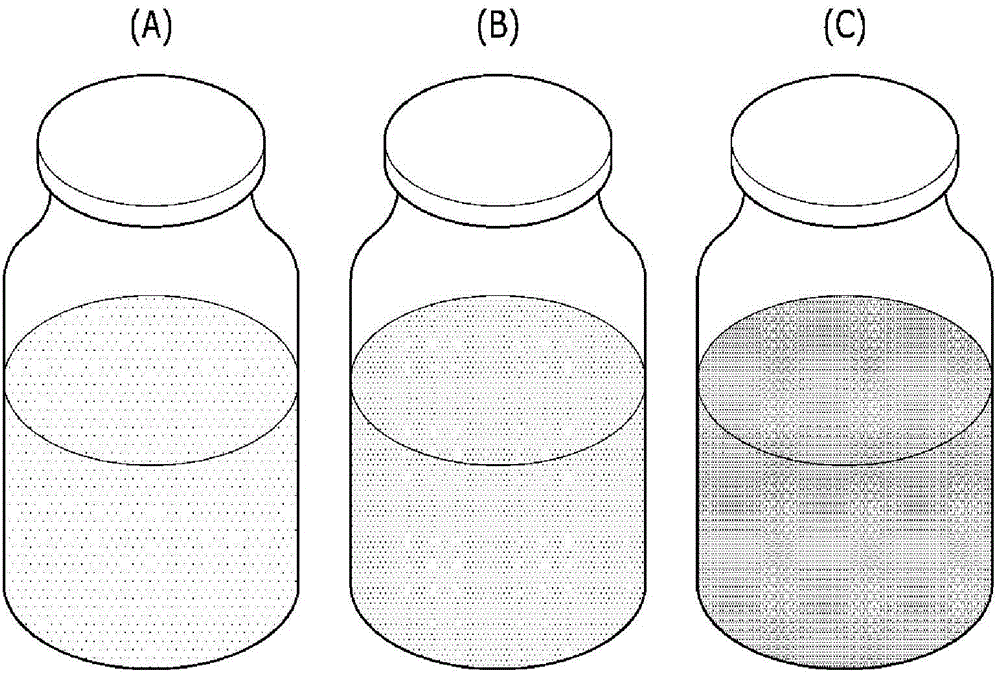

[0058] (Preparation of GO slurry containing IPA)

[0059] 100 g of aqueous GO slurry (eg, 2.5% solids content by thermal analysis) was placed in a 500 ml plastic bottle, 300 ml of IPA was added thereto, and the mixture was ultrasonically dispersed for 5 min. Centrifuge H at 3000 rpm 2 GO solution dispersed in O / IPA, the supernatant was removed, and the IPA addition process and supernatant removal process were repeated 10 times. Thus, an IPA-containing GO slurry was obtained. When the IPA addition-dispersion-centrifugation-supernatant removal process was performed at least three times, H 2 The removal efficiency of O is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com