Water-resistance thermosensitive color-changing liquid wall paper and preparation method thereof

A temperature-sensitive discoloration and liquid wallpaper technology, applied in heat-sensitive coatings, coatings, etc., can solve the problems of poor water resistance and corrosion resistance, wear resistance and adhesion, etc., to improve water resistance and remind environmental protection Consciousness, the effect of excellent atmospheric aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] (1) Mix and stir distilled water, dispersant sodium hexametaphosphate, and wetting agent sodium tripolyphosphate, then add temperature-changing materials, stir well, add co-solvent ethylene glycol, and stir until uniform, and make temperature-changing powder pulp.

[0017] (2) Silicone acrylic emulsion was prepared by pre-emulsified seed emulsion polymerization: 1) The monomers butyl acrylate, vinyl acetate, N-methylol acrylamide, acrylic acid, and hydroxyethyl acrylate were prepared according to the mass ratio of butyl acrylate: acetic acid Vinyl ester: N-methylolacrylamide: acrylic acid: hydroxyethyl acrylate mass ratio 60:30:2:5:3 Add in distilled water, total monomer: distilled water mass ratio is 35:65, add compound emulsification under stirring Agent, compound emulsifier ethylene glycol, sodium lauryl sulfate, alkylphenol polyoxyethylene ether is composed of 1:1:1 by mass ratio, the compound emulsifier is 3% of the total mass of the monomer, high shear dispersion ...

Embodiment 2

[0020] (1) Mix and stir distilled water, dispersant sodium lauryl sulfate, and wetting agent sodium tripolyphosphate, then add the temperature-changing material, after fully stirring, add co-solvent ethylene glycol butyl ether, and then fully stir until uniform. into a temperature-varying powder slurry.

[0021] (2) Same as embodiment 1.

[0022] (3) In the temperature-changing powder slurry prepared in step (1), add film-forming aid alcohol ester-12, extender pigment, antifungal agent benzimidazole ester in sequence, stir for 0.5 hours, and then slowly add step (2) Add the thickener carboxymethyl cellulose and defoamer n-butanol to the prepared silicon-acrylic emulsion, and stir at a slow speed for 2 hours to obtain a water-resistant temperature-sensitive color-changing liquid wallpaper.

Embodiment 3

[0024] (1) Mix and stir distilled water, dispersant sodium hexametaphosphate, and wetting agent tetrapotassium pyrophosphate, then add temperature-changing materials, stir well, add co-solvent turpentine, and then fully stir until uniform to make temperature-changing powder slurry.

[0025] (2) Same as embodiment 1.

[0026] (3) Add coalescent agent propylene glycol phenyl ether, extender pigment, antifungal agent butynediol to the temperature-changing powder slurry prepared in step (1) in sequence, stir for 0.5 hours, and then slowly add step (2) under stirring ) prepared silicone acrylic emulsion, finally add thickener methyl cellulose, defoamer organosiloxane plus polyether, and stir at a slow speed for 2 hours to obtain a water-resistant temperature-sensitive color-changing liquid wallpaper.

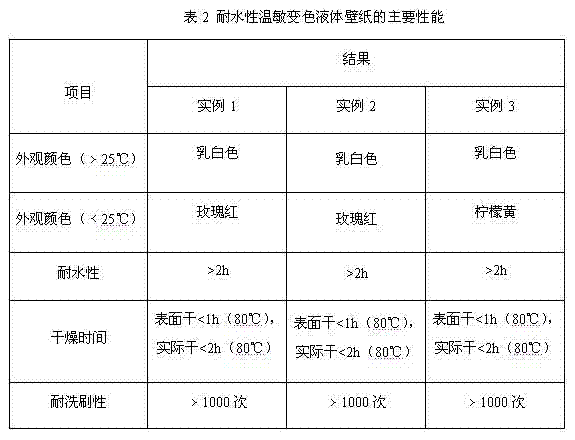

[0027] See Table 1 for the mass ratio of each component in Examples 1 to 3.

[0028]

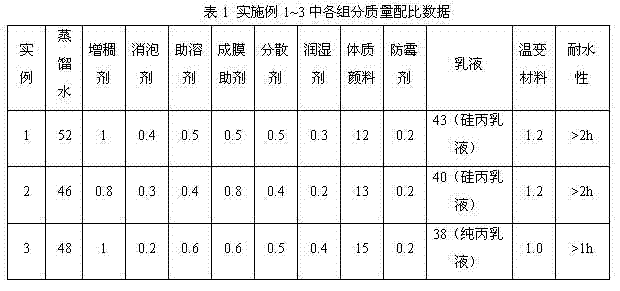

[0029] The performance test results of the temperature-sensitive color-changing wallpaper i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discoloration temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com