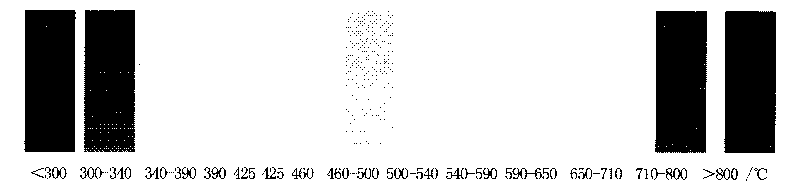

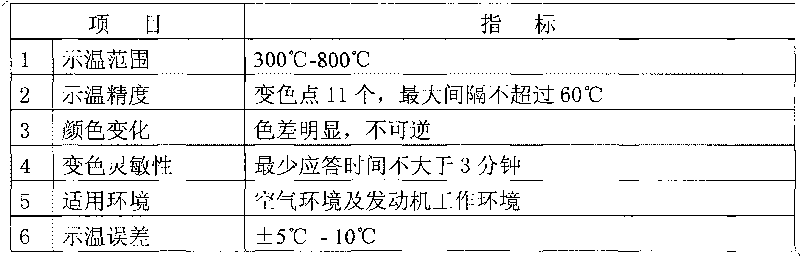

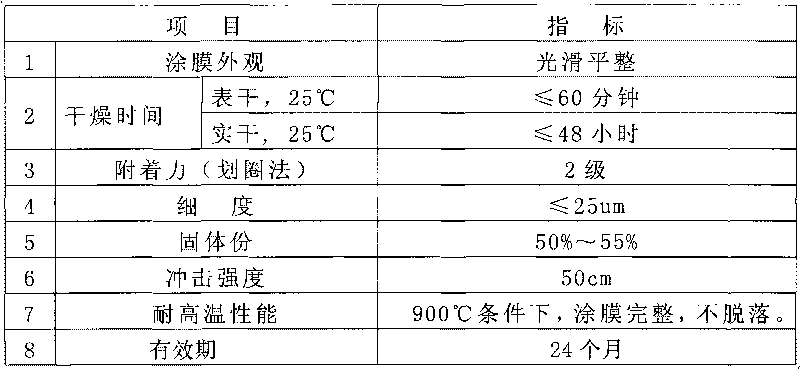

300 DEG C-800 DEG C pleochromatic irreversible thermopaint

A technology for temperature-indicating paints and paints, applied in heat-sensitive paints, epoxy resin paints, coatings, etc., can solve the problems of inconspicuous color difference, large temperature display error, unstable product quality, etc., and achieve the effect of convenient temperature reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The paint formulation is:

[0063] Component A: silicone modified epoxy resin solution 40.0g

[0064] Phthalocyanine blue GB 0.9g

[0065]Phthalocyanine blue G 0.5g

[0066] Phthalocyanine Green 0.3g

[0067] Composite thermochromic pigment 15.0g

[0068] Ceramic red on glaze 5.7g

[0069] Fruit Green Glaze 1.4g

[0070] Glass powder 1.1g

[0072] Kaolin 1.7g

[0075] Silicone coupling agent KH550 1.0g

[0076] Dispersant 104S 1.0g

[0077] Xylene 20.0g

[0078] Component B: 60% TDI trimer liquid 8.0g

[0079] Component A: Weigh 1.1g of glass powder, 1.4g of talc powder, 1.7g of kaolin, 1.0g of magnesium oxide and 1.2g of calcium oxide, mix them, add 10.0g of xylene and 1.0g of organic silicon coupling agent KH5501, and stir for 30 minutes. After standing for 60 minutes, pour into the mixing bucket. Weigh other materials according to the coating formula, add them into the ...

Embodiment 2

[0082] The paint formulation is:

[0083] Component A: Silicone modified epoxy resin solution 45.0g

[0084] Phthalocyanine blue GB 0.7g

[0085] Phthalocyanine blue G 0.5g

[0086] Phthalocyanine Green 0.2g

[0087] Composite thermochromic pigment 20.0g

[0088] Ceramic Red On Glaze 5.0g

[0089] Glazed Fruit Green 1.2g

[0090] Glass powder 1.3g

[0091] Talc powder 1.5g

[0092] Kaolin 1.2g

[0093] Magnesium oxide 0.8g

[0095] Silicone coupling agent KH550 0.8g

[0096] Dispersant 104S 0.6g

[0097] Xylene 18.0g

[0098] Component B: 60% TDI trimer liquid 8.5g

[0099] Component A: Mix glass powder, talcum powder, kaolin, magnesium oxide and calcium oxide according to the formula, add xylene 10.0g and organic silicon coupling agent KH5500.8g, stir for 30 minutes, place for 60 minutes, pour into the mixing bucket. Weigh other materials according to the coating formula, add them into the mixing tank, stir evenly, grind and disperse...

Embodiment 3

[0101] The paint formulation is:

[0102] Component A: Silicone modified epoxy resin solution 45.0g

[0103] Phthalocyanine blue GB 1.0g

[0104] Phthalocyanine blue G 0.5g

[0105] Phthalocyanine Green 0.2g

[0106] Composite thermochromic pigment 19.0g

[0107] Ceramic red on glaze 5.2g

[0108] Fruit Green Glaze 1.4g

[0109] Glass powder 1.0g

[0110] Talc powder 1.7g

[0111] Kaolin 1.0g

[0112] Magnesium oxide 1.2g

[0114] Silicone coupling agent KH550 1.0g

[0115] Dispersant 104S 0.8g

[0116] Xylene 20.0g

[0117] Component B: 60% TDI trimer liquid 8.5g

[0118] Preparation: For component A, weigh glass powder, talcum powder, kaolin, magnesium oxide and calcium oxide according to the formula, add 10.0g of xylene and 0.8g of organic silicon coupling agent KH5500.8g, stir for 30 minutes, stand for 60 minutes, pour into the mixing tank. Weigh other materials according to the coating formula, add them into the mixing tank, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com