Reversibly thermochromic composition

A thermochromic and composition technology, applied in the direction of color-changing fluorescent materials, heat-sensitive coatings, structure changes of writing utensils, etc., can solve the problems of unsmooth writing feeling, difficult to fade, and fading, etc., and achieve the effect of improving visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 101~106 and comparative example 101~106

[0270] The compositions of the solid writing materials of Examples and Comparative Examples are shown in the following table. In addition, the numerical value of the composition in a table shows a mass part. In addition, the particle size of the microcapsule pigment was measured with a laser diffraction / scattering type particle size distribution measuring device Model LA-300 (trade name, manufactured by Horiba Seisakusho Co., Ltd.), and the average particle size was calculated on a volume basis based on the value. (median particle diameter) obtained value.

[0271]

[0272] The contents of the raw materials in the table are explained according to the comment numbers.

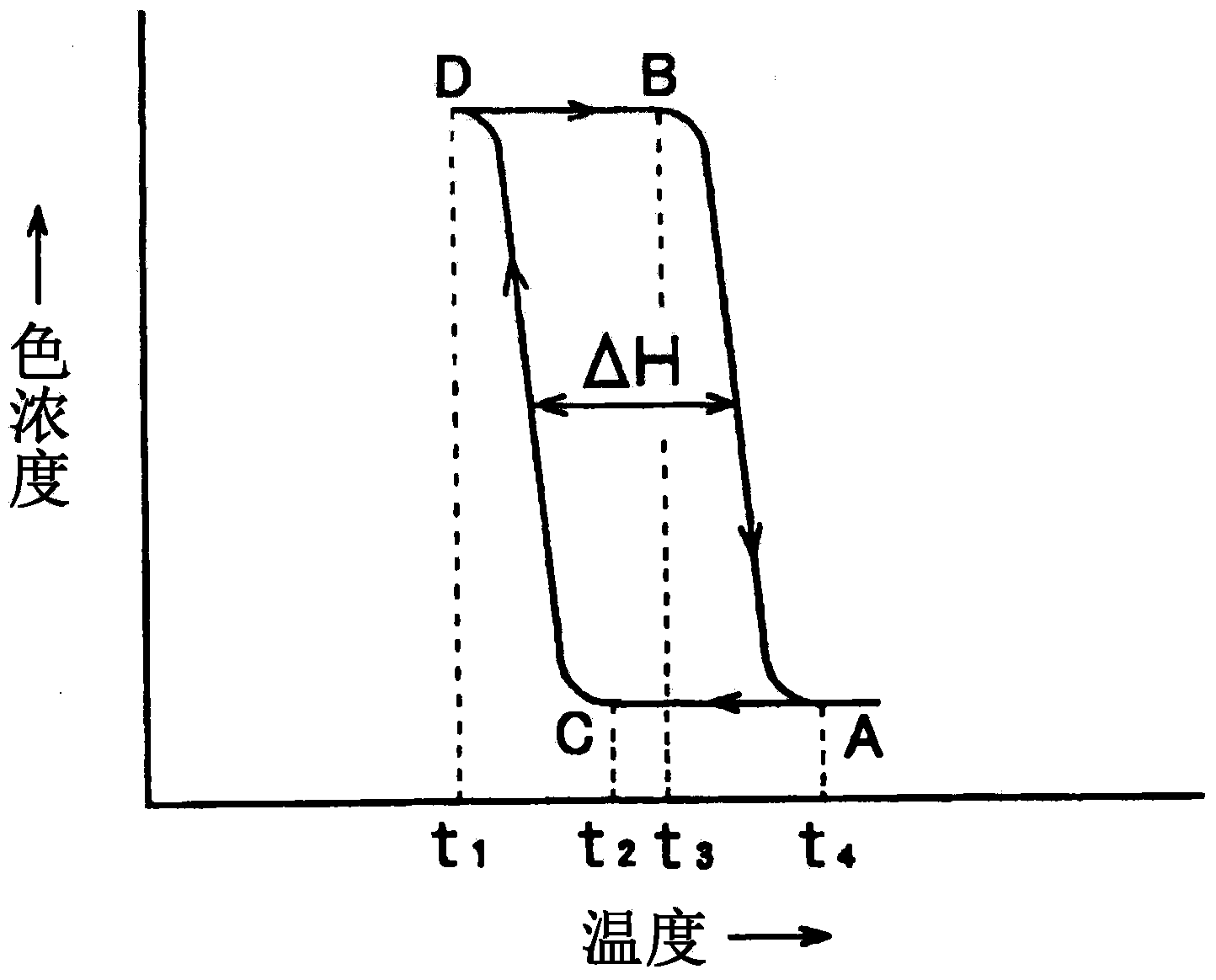

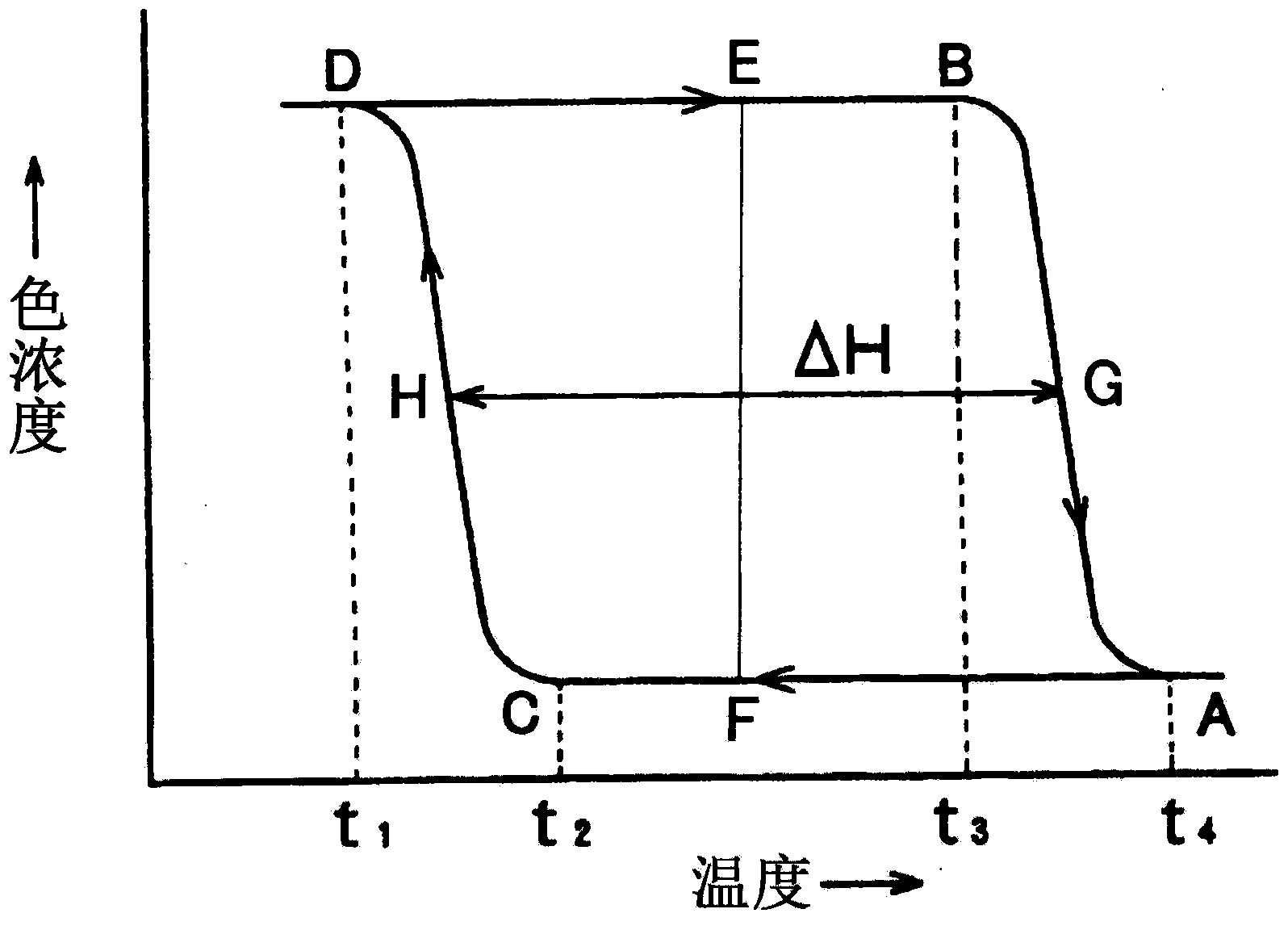

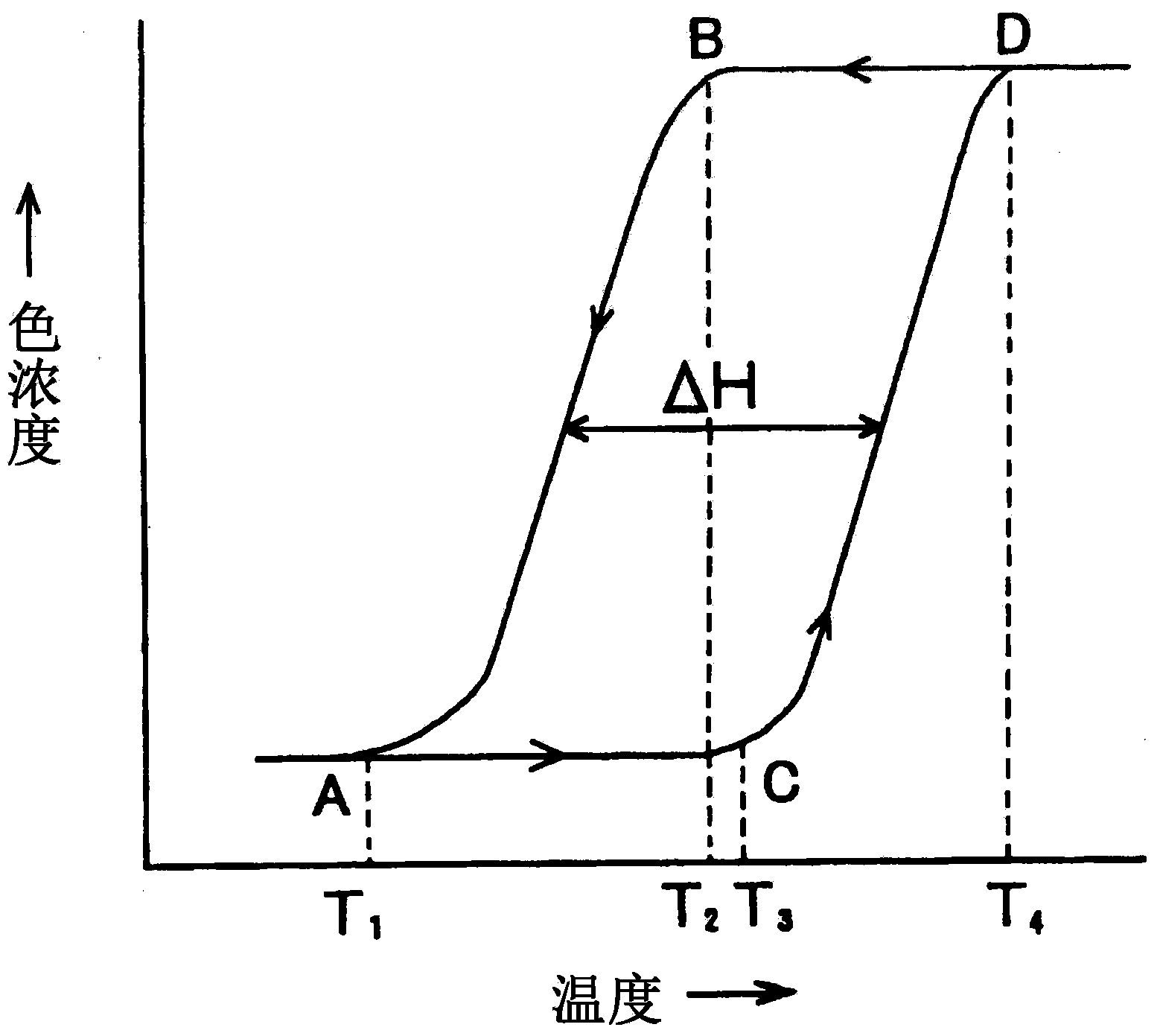

[0273] (1) Reversible thermochromic microcapsule pigment (T 1 : -16°C, T 2 : -8°C, T 3 : 48°C, T 4 : 58°C, ΔH: 65°C, average particle size: 2.5 μm, reversible thermochromic composition: wall film = 2.6:1.0, color changes from blue to colorless), the heat-fading type reversible thermochromic composition ...

Embodiment 201

[0329] (Production of reversible thermochromic composition)

[0330] Thermochromic Microcapsule A 18 parts by mass

[0331] Myristyl alcohol (endothermic phase transition compound) 20 parts by mass

[0332] 32 parts by mass of ion-exchanged water

[0333] Stir the above mixture with a magnetic stirrer until uniform. The obtained mixture was dried at room temperature, whereby a reversible thermochromic composition 201 was obtained.

Embodiment 202~211

[0335] A reversible thermochromic composition was obtained in the same manner as in Example 201, except that the thermochromic microcapsules and endothermic microcapsules shown in Table 4 were used instead of the thermochromic microcapsules A and myristyl alcohol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com