Thermochromic coating for metal, glass and ceramic and preparation method thereof

A temperature-sensitive color-changing and temperature-changing pigment technology, which is applied in the field of temperature-sensitive color-changing coatings and its preparation, can solve the problems of not being able to display the surface temperature of the product, the paint on the product surface falling off, and the product being exposed to the environment, so as to achieve good color retention effect, Good weather resistance, excellent fullness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

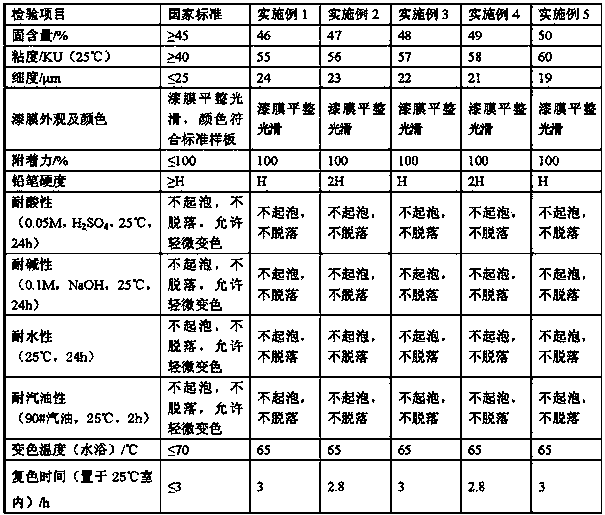

Examples

Embodiment 1

[0073] A temperature-sensitive color-changing coating for metal, glass and ceramics, comprising the following raw materials in parts by weight: 16 parts of polyurethane resin, 6 parts of thermosetting acrylic resin, 3 parts of permethyletherified amino resin, 16 parts of temperature-changing pigment, 0.5 parts of leveling agent, 1 part of defoamer, 0.5 parts of dispersant and 23 parts of organic solvent.

[0074] Wherein, the polyurethane resin has a density of 1.33g / cm 3 , a polyurethane resin with a viscosity of 1000mPa.s; the thermosetting acrylic resin has a density of 0.97g / cm 3 , a thermosetting acrylic resin with a viscosity of 45mPa.s; the full methyl etherified amino resin has a density of 1.14g / cm 3 , a full methyl etherified amino resin with a viscosity of 4500mPa.s.

[0075] Wherein, the temperature-changing pigment is 3,6-dimethoxyfluorane; the leveling agent is a fluorine-modified acrylic leveling agent; the defoamer is a silicone defoamer; the The dispersant ...

Embodiment 2

[0081] A temperature-sensitive color-changing paint for metal, glass and ceramics, comprising the following raw materials in parts by weight: 20 parts of polyurethane resin, 8 parts of thermosetting acrylic resin, 4 parts of permethyl etherified amino resin, 20 parts of temperature-changing pigment, 0.75 parts of leveling agent, 1.5 parts of defoamer, 0.75 parts of dispersant and 28.5 parts of organic solvent.

[0082] Wherein, the polyurethane resin has a density of 1.34g / cm 3 , a polyurethane resin with a viscosity of 1100mPa.s; the thermosetting acrylic resin has a density of 0.98g / cm 3 , a thermosetting acrylic resin with a viscosity of 48mPa.s; the full methyl etherified amino resin has a density of 1.11g / cm 3 , a full methyl etherified amino resin with a viscosity of 4800mPa.s.

[0083] Wherein, the temperature-changing pigment is 3-cyclohexylamino-6-chlorofluorane; the leveling agent is a fluorine-modified acrylic leveling agent; the defoamer is a silicone defoamer; ...

Embodiment 3

[0089] A temperature-sensitive color-changing coating for metal, glass and ceramics, comprising the following raw materials in parts by weight: 24 parts of polyurethane resin, 10 parts of thermosetting acrylic resin, 5 parts of permethyletherified amino resin, 25 parts of temperature-changing pigment, 1 part of leveling agent, 2 parts of defoamer, 1 part of dispersant and 34 parts of organic solvent.

[0090] Wherein, the polyurethane resin has a density of 1.36g / cm 3 , a polyurethane resin with a viscosity of 1200mPa.s; the thermosetting acrylic resin has a density of 1.00g / cm 3 , a thermosetting acrylic resin with a viscosity of 50mPa.s; the full methyl etherified amino resin has a density of 1.16g / cm 3 , a full methyl etherified amino resin with a viscosity of 5200mPa.s.

[0091] Wherein, the temperature-changing pigment is rhodamine B lactam; the leveling agent is a fluorine-modified acrylic leveling agent; the defoamer is a silicone defoamer; the dispersant is an alkyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com