Graphene heat dissipation coating

A heat-dissipating coating and graphene technology, applied in the field of coatings and new coatings, can solve the problems of unfavorable batch production and large-scale application of coatings, complex production process, expensive price, etc., to achieve the release of heat, simple preparation process, Improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

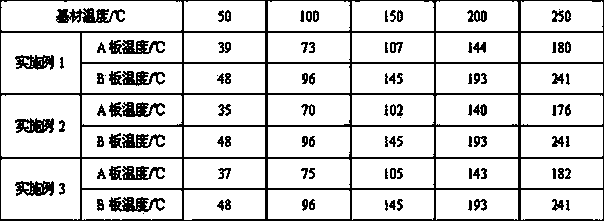

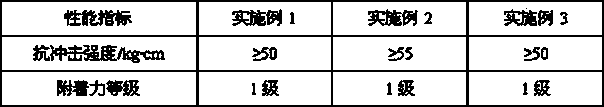

Embodiment 1

[0015] 52 parts of epoxy acrylic resin, 5 parts of graphene, 65 parts of water, 11 parts of phthalocyanine blue, 5 parts of polyethylene wax, 5 parts of polydimethylsiloxane, 5 parts of ethylenediamine, aminopropyl trimethyl 5 parts of oxysilane.

[0016] (1) Mix 52 parts of epoxy acrylic resin, 5 parts of graphene, and 65 parts of water into the mixer, control the speed at 1000 rpm, and stir for 1 hour;

[0017] (2) Add 5 parts of polyethylene wax, 5 parts of polydimethylsiloxane, 5 parts of ethylenediamine and 5 parts of aminopropyltrimethoxysilane to the mixer in sequence, control the speed at 800rpm, and stir for 0.5h ;

[0018] (3) Add 11 parts of phthalocyanine blue to the mixer, control the speed at 500rpm, and mix well to obtain the cyan graphene heat dissipation coating.

Embodiment 2

[0020] 74 parts of epoxy acrylic resin, 7 parts of graphene, 76 parts of water, 13 parts of azo red, 7 parts of polyethylene wax, 6 parts of polydimethylsiloxane, 8 parts of ethylenediamine, aminopropyl trimethyl 5 parts of oxysilane.

[0021] (1) Mix 74 parts of epoxy acrylic resin, 7 parts of graphene, and 76 parts of water into the mixer, control the speed at 1200 rpm, and stir for 1.5 hours;

[0022] (2) Add 7 parts of polyethylene wax, 6 parts of polydimethylsiloxane, 8 parts of ethylenediamine and 5 parts of aminopropyltrimethoxysilane to the mixer in sequence, control the speed at 900rpm, and stir for 0.7h ;

[0023] (3) Add 13 parts of azo red to the mixer, control the rotation speed to 700rpm, and mix well to obtain the red graphene heat dissipation coating.

Embodiment 3

[0025] 80 parts of epoxy acrylic resin, 10 parts of graphene, 80 parts of water, 15 parts of azo blue, 7 parts of polyethylene wax, 8 parts of polydimethylsiloxane, 8 parts of ethylenediamine, aminopropyl trimethyl 7 parts of oxysilane.

[0026] (1) Mix 80 parts of epoxy acrylic resin, 10 parts of graphene, and 80 parts of water into the mixer, control the speed at 1500 rpm, and stir for 1.8 hours;

[0027] (2) Add 7 parts of polyethylene wax, 8 parts of polydimethylsiloxane, 8 parts of ethylenediamine and 7 parts of aminopropyltrimethoxysilane to the mixer in sequence, control the speed at 1000rpm, and stir for 0.8h ;

[0028] (3) Add 15 parts of azo blue to the mixer, control the speed at 800rpm, and mix well to obtain the blue graphene heat dissipation coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com