Production method of phthalocyanine blue 15:4 for toluene ink

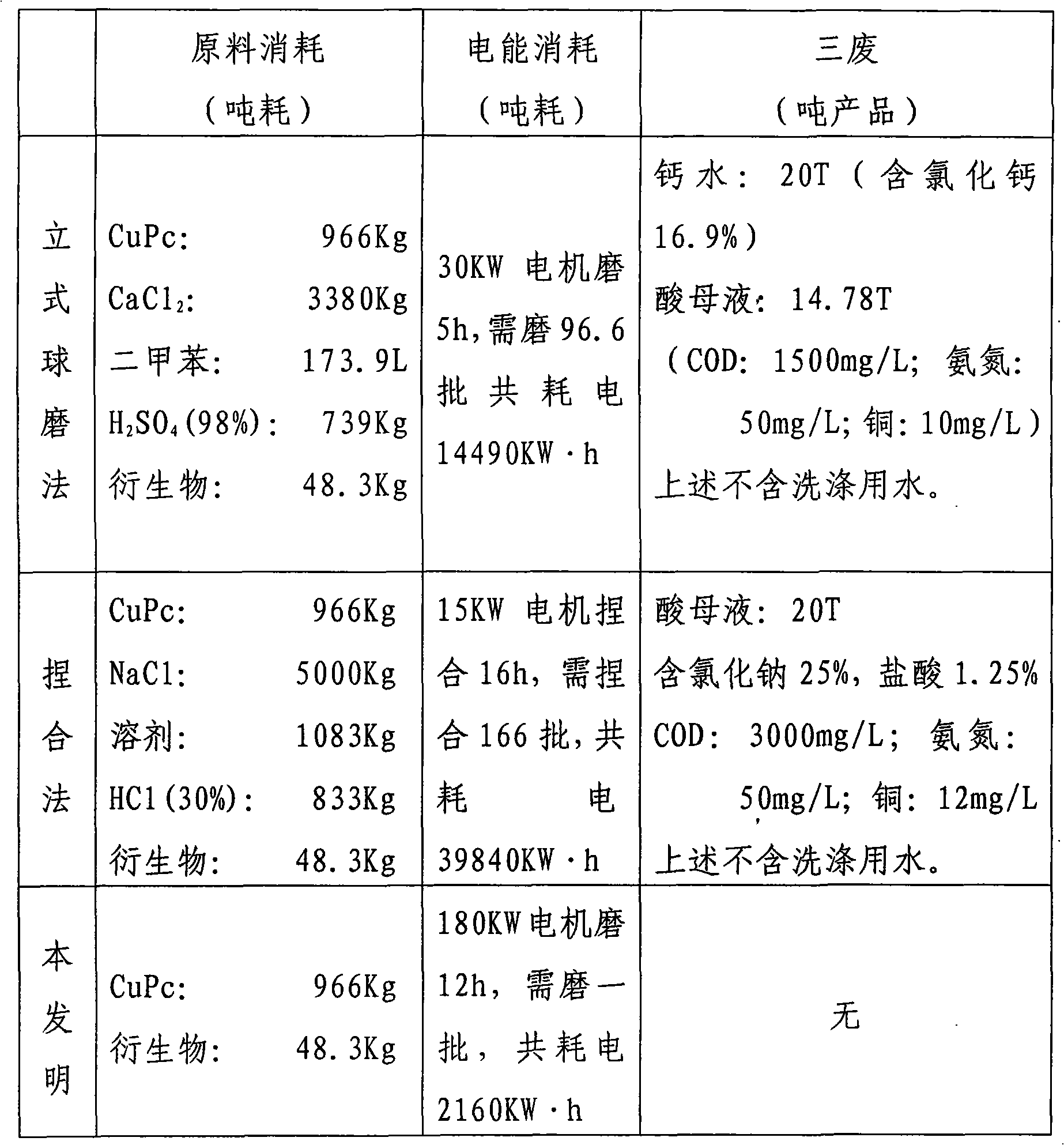

A production method, the technology of phthalocyanine blue, which is applied in the production field of phthalocyanine blue 15:4 for toluene ink, can solve the problems of serious COD emission, large consumption of raw materials, large power consumption, etc., and achieves small environmental impact and short production process , the effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

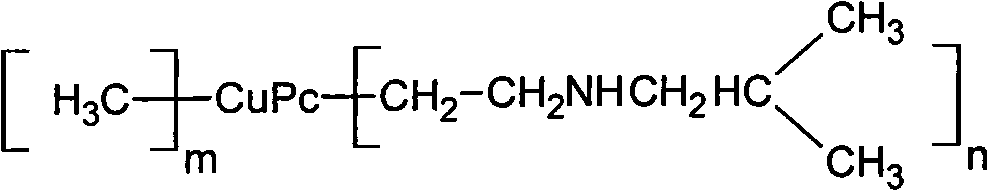

[0035] Example 1: Add 1000kg of crude copper phthalocyanine with purity ≥98.5% and free copper content ≤1000ppm to a 10000L horizontal ball mill, and add 30kg of copper phthalocyanine derivative shown in the raw material selection, turn on the ball mill for ball milling, and pass Adjust the temperature of the materials in the cooling water control machine at 125±2°C and ball mill for 12 hours to obtain a ball milled product containing 38% α crystal form. The ball milled product was passed through a magnetic filter to remove the iron produced during the ball milling, and the product was collected to obtain a phthalocyanine blue 15:4, 1# sample with an average particle size of less than 1 μm.

Embodiment 2

[0036] Example 2: Add 1000kg of crude copper phthalocyanine with purity ≥98.5% and free copper content ≤1000ppm to a 10000L horizontal ball mill, and add 30kg of copper phthalocyanine derivative shown in the raw material selection, turn on the ball mill for ball milling, and pass Adjust the temperature of the materials in the cooling water control machine at 135±2°C, and ball mill for 12 hours to obtain a ball milled product containing 35% of α crystal form. The ball milled product was passed through a magnetic filter to remove the iron produced during ball milling, and the product was collected to obtain phthalocyanine blue 15:4, 2# sample. The average particle size of the pigment was less than 1 μm.

Embodiment 3

[0037] Example 3: 1000kg of crude copper phthalocyanine with purity ≥98.5% and free copper content ≤1000ppm is added to a 10000L horizontal ball mill, and 30kg of copper phthalocyanine derivative shown in the raw material selection is added, and the ball mill is turned on for ball milling and passed Adjust the temperature of the material in the cooling water control machine at 150±2°C and ball mill for 12 hours to obtain a ball milled product containing 31% α crystal form. The ball milled product was passed through a magnetic filter to remove the iron produced during the ball milling, and the product was collected to obtain phthalocyanine blue 15:4, 3# sample. The average particle size of the pigment was less than 1 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com