Powdered ink for laser blueprint machine and manufacturing method of powdered ink

A manufacturing method and blueprint technology, applied in the field of printing materials, can solve problems such as weak fixation, high softening temperature of toner, damage to printers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

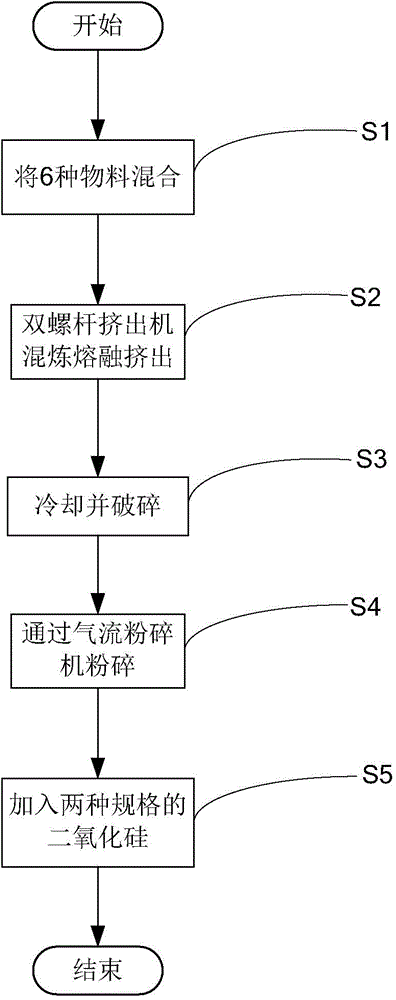

[0031] Such as figure 1 As shown, when making the toner of this embodiment, first perform step S1, 100 parts by mass of ethylene glycol phthalate copolymer, 30 parts by mass of styrene butyl acrylate copolymer, 6 parts by mass of phthalate Cyanine blue, phthalocyanine red in 4 parts by mass, polypropylene wax in 4 parts by mass and charge control agent in 2 parts by mass, a total of 6 kinds of materials were put into the Henschel high-speed mixer and mixed to obtain the first mixture. The high-speed mixer The rotating speed is 950rpm, and the time is 5 minutes.

[0032] Then step S2 is executed, the first mixture is melt-kneaded and extruded into the second mixture through a twin-screw extruder, the melt temperature of the melt-kneading is controlled at 100° C., and step S2 is repeated once.

[0033] Then step S3 is executed, the second mixture is rapidly cooled by a blower, and crushed by a hammer crusher to obtain a third mixture with a particle size of 0.1 mm to 1 mm.

[...

no. 2 example

[0038] When making the toner of the present embodiment, first, 100 parts by mass of polyester resin, 25 parts by mass of styrene acrylic resin, 9 parts by mass of phthalocyanine blue, 1 part by mass of phthalocyanine red, 4 parts by mass of polypropylene The wax and 2 parts by mass of the charge control agent were put into a Henschel high-speed mixer and mixed to obtain the first mixture at a rotation speed of 950 rpm for 5 minutes.

[0039] Then, the first mixture is melt-kneaded and extruded into the second mixture through a twin-screw extruder, and the process of melt-kneading and extrusion by the twin-screw extruder needs to be repeated once, and the melt temperature of the melt-kneading is controlled at 150°C . After the second mixture is rapidly cooled by a blower, it is crushed by a hammer crusher to obtain a third mixture with a particle size of 0.1 mm to 1 mm.

[0040] The third mixture was further pulverized by a jet mill to obtain basic particles with an average pa...

no. 3 example

[0043] When making the toner of the present embodiment, the polyester resin of 100 mass parts, the styrene acrylic resin of 14 mass parts, the phthalocyanine blue of 4 mass parts, the phthalocyanine red of 0.5 mass parts, the polypropylene wax of 4 mass parts and 2 parts by mass of the charge control agent were put into a Henschel high-speed mixer and mixed to obtain the first mixture at a rotation speed of 950 rpm for 5 minutes.

[0044] The first mixture is melted and kneaded by the twin-screw extruder to be extruded into the second mixture, and the process of the twin-screw extruder to perform the melt kneading and extrusion needs to be repeated once, and the melt temperature of the melt kneading is controlled at 110°C. After the second mixture is rapidly cooled by a blower, it is crushed by a hammer crusher to obtain a third mixture with a particle size of 0.1 mm to 1 mm.

[0045] The third mixture was further pulverized by a jet mill to obtain basic particles with an aver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com