Toner and image forming method

a technology applied in the field of toner and image forming method, can solve the problems of easy scattering of toner, easy leakage of toner, and hardly obtained images with constant quality, and achieve excellent image stability, efficient and uniform frictional charging, and excellent image stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

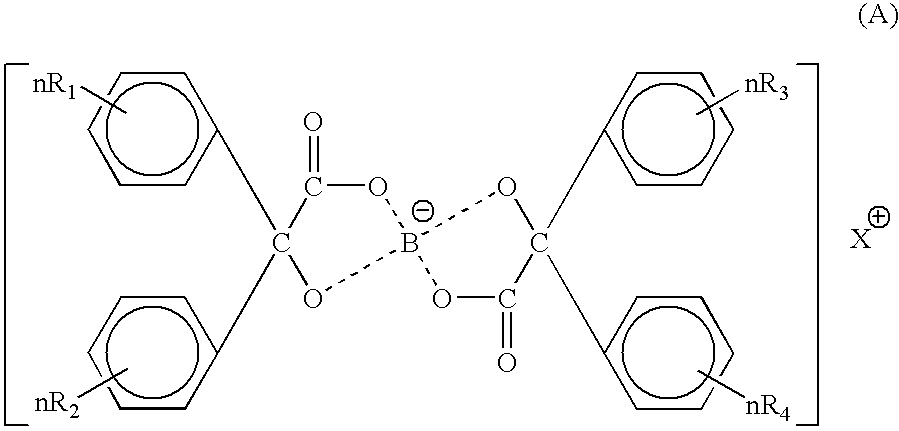

Method used

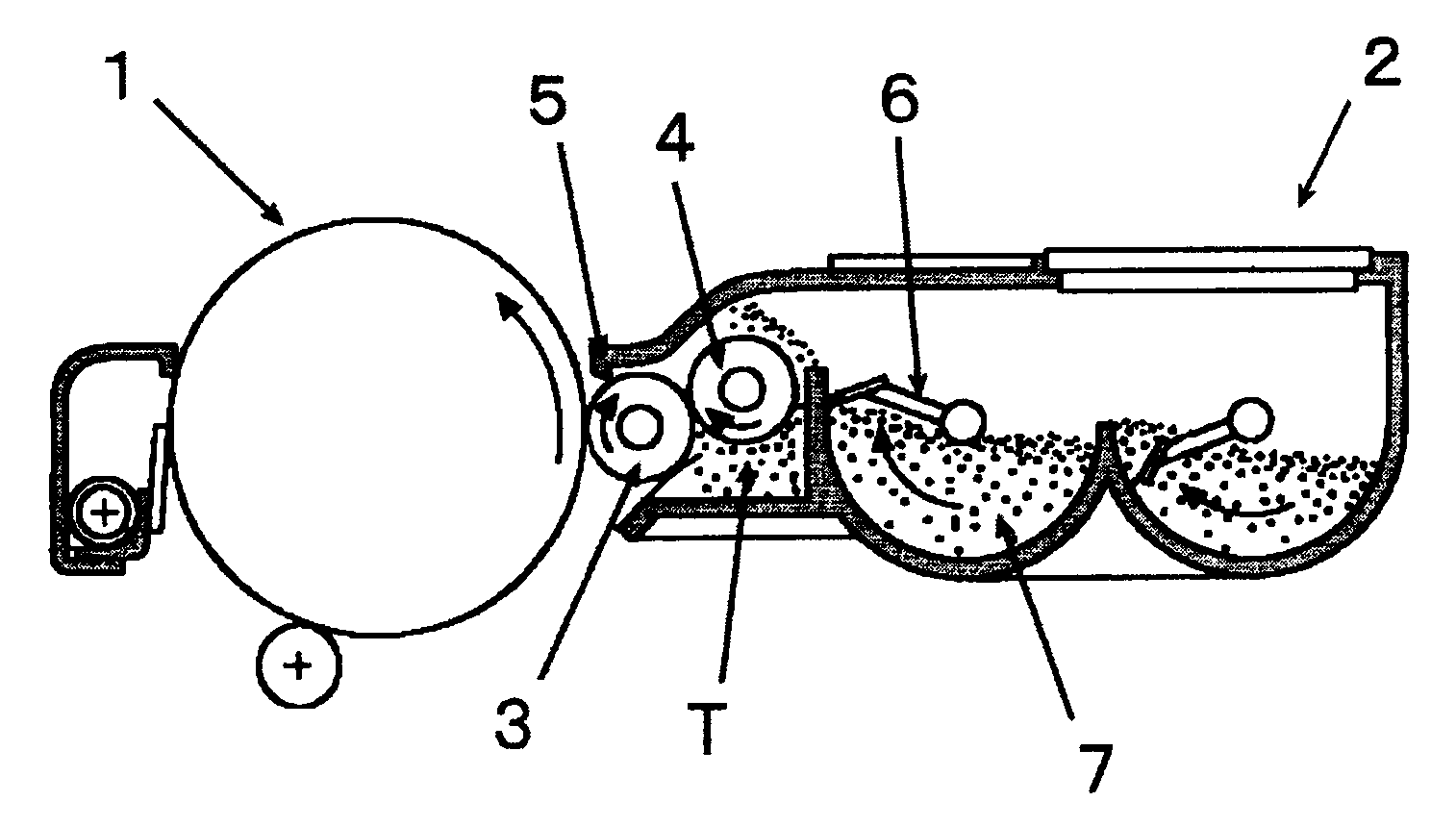

Image

Examples

example 1

[0138]To 100 parts by mass of the colored resin particles obtained as the above, 1 part by mass of the forsterite 1 (first inorganic fine particle) and 1 part by mass of silica RX200 (supplied from Japan Aerosil Co., Ltd., primary particle diameter: 12 nm, HMDS surface treatment) were added, and mixed using the Henschel mixer (at a peripheral velocity of 40 m / s for 60 seconds) to make the cyan toner 1.

[0139]The results of evaluating the toners obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com