Main valve element of precise pressure reducing valve and production technology

A technology of pressure reducing valve and main valve core, which is applied to valve devices, engine components, mechanical equipment, etc., can solve the problems of complex structure, high requirements on smoothness and concentricity, and low processing qualification rate of main valve core, etc. The effect of processing qualification rate, simple processing technology and quality index improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

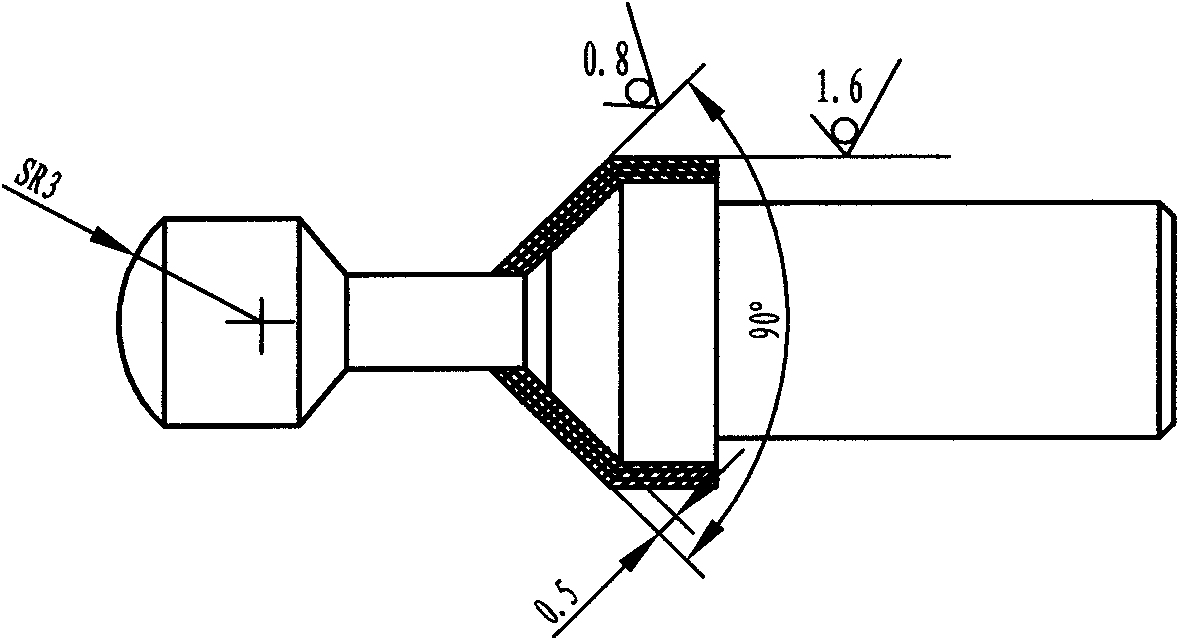

[0022] The structure of the main spool of the traditional precision pressure reducing valve is shown in figure 1 , it adopts an integral structure. The SR3 spherical surface is generally processed by a precision lathe, which requires high precision and non-concentricity. At the same time, due to the complex overall structure, it brings difficulties to the vulcanization of its shoulder. Therefore, the pass rate of this main valve core It is difficult to achieve large-scale production.

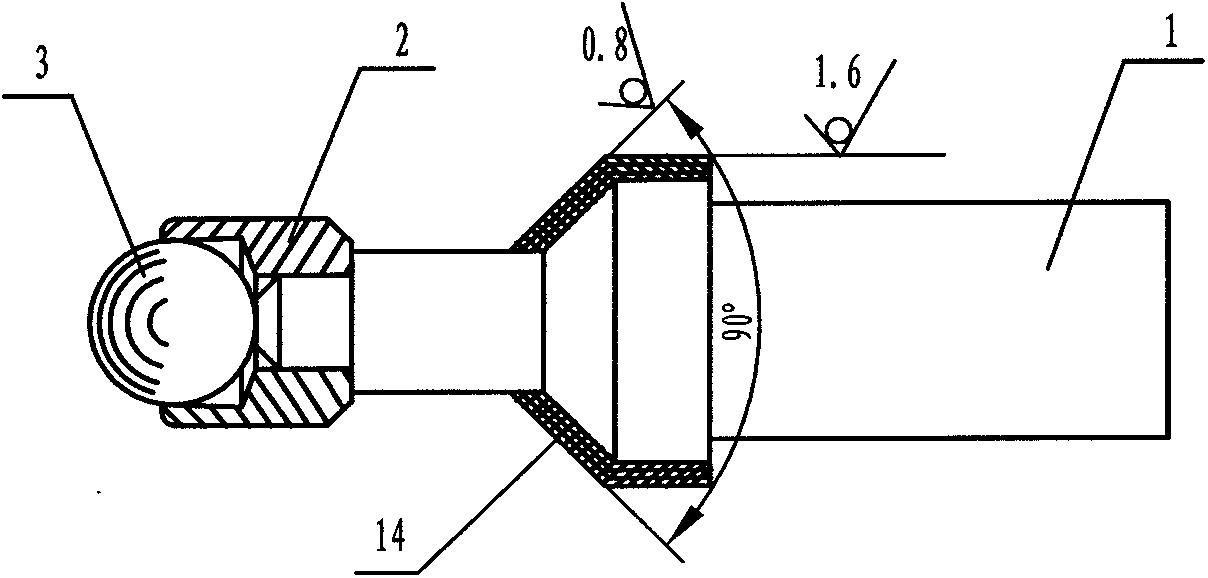

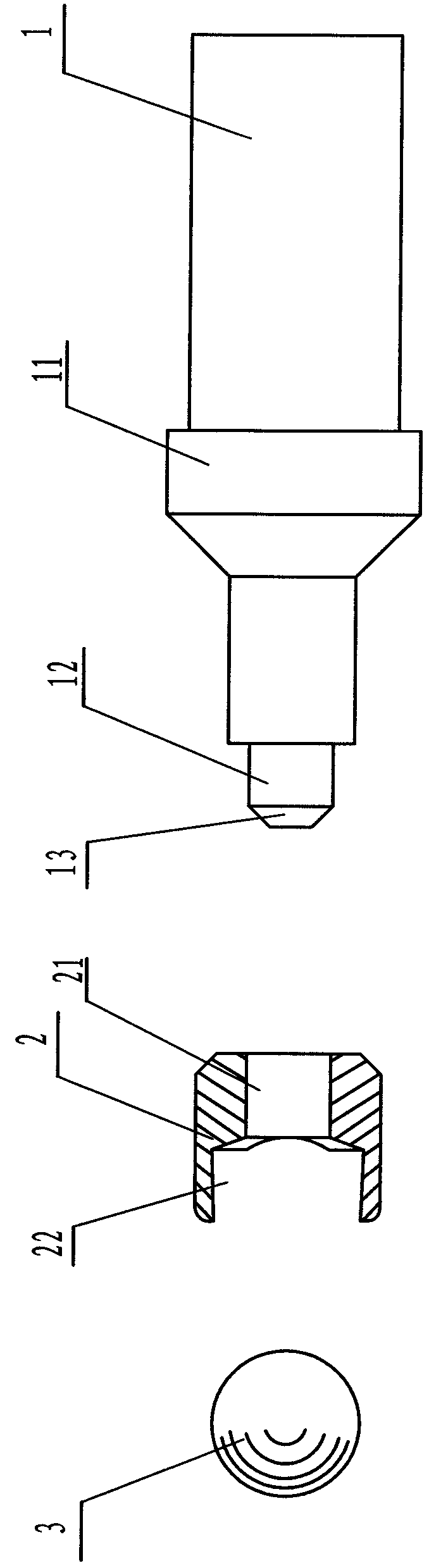

[0023] The structure of the main valve core of the precision pressure reducing valve of the present invention is shown in figure 2 , image 3 , comprising a valve stem 1, a connecting sleeve 2, and a steel ball 3, the end of the valve stem is turned with a connecting section 12, the top of the connecting section is turned with a conical shoulder 13, and the middle of the valve stem is turned with a shoulder-shaped step 11. A nitrile rubber layer 14 is vulcanized on the shoulder-shaped step. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com