Method for processing industry high-concentration ammonia nitrogen wastewater

An ammonia nitrogen wastewater, high-concentration technology, applied in chemical instruments and methods, degassed water/sewage treatment, water/sludge/sewage treatment, etc. dirt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

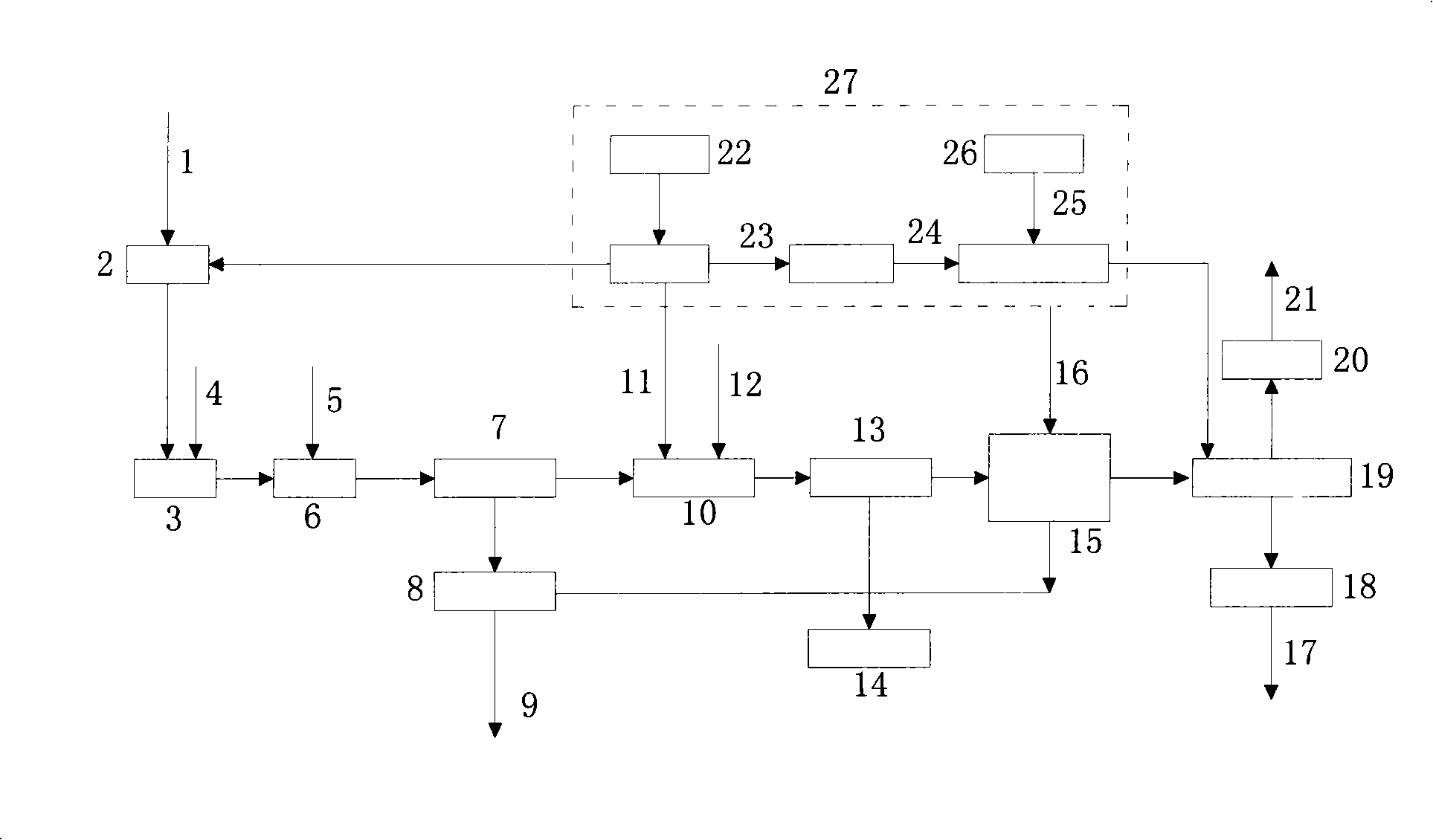

[0024] process flow

[0025] The high-concentration ammonia nitrogen wastewater treatment process is shown in Figure 1. In Figure 1, (1) is the production sewage, (2) is the regulating tank, (3) is the coagulation, (4) is the coagulant, and (5) is the auxiliary Coagulant, (6) is coagulation aid, (7) is high-density clarification, (8) is sludge dehydration, (9) is sludge combustion, (10) is deployment tank, (11) is conditioner, (12) is a denitrification catalyst, (13) is a denitrification tower, (14) is ammonia recovery, (15) is a tempering inclined tube sedimentation tank, (16) is a conditioning agent, (17) is clear water reuse, (18) is a clear water pool, (19) is an adsorption oxidation tower, (20) is tail gas decomposition, (21) is emptying, (22) is an air compressor, (23) is an air storage tank, (24) is air Drying, (25) is an ozone generator, (26) is a power supply system, and (27) is a gas and ozone generator.

[0026] The process is: the production wastewater first ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com