Process fault analysis device of process industry system and method therefor

A fault analysis and process industry technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as increasing the burden of fault monitoring and analysis and calculation, abnormal identification and separation ability, and multi-noise information, etc. Knowledge or experience to select monitoring points, improve fault identification and separation capabilities, and monitor timely and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

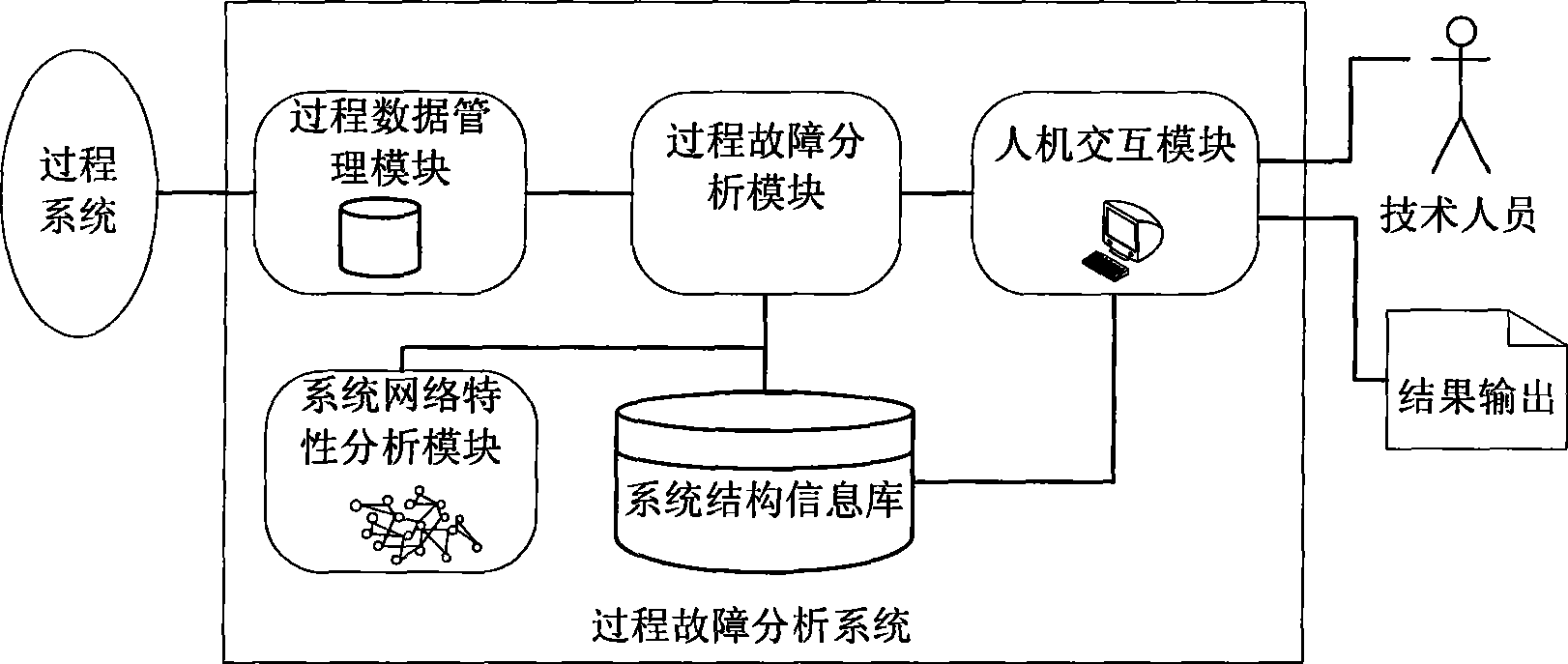

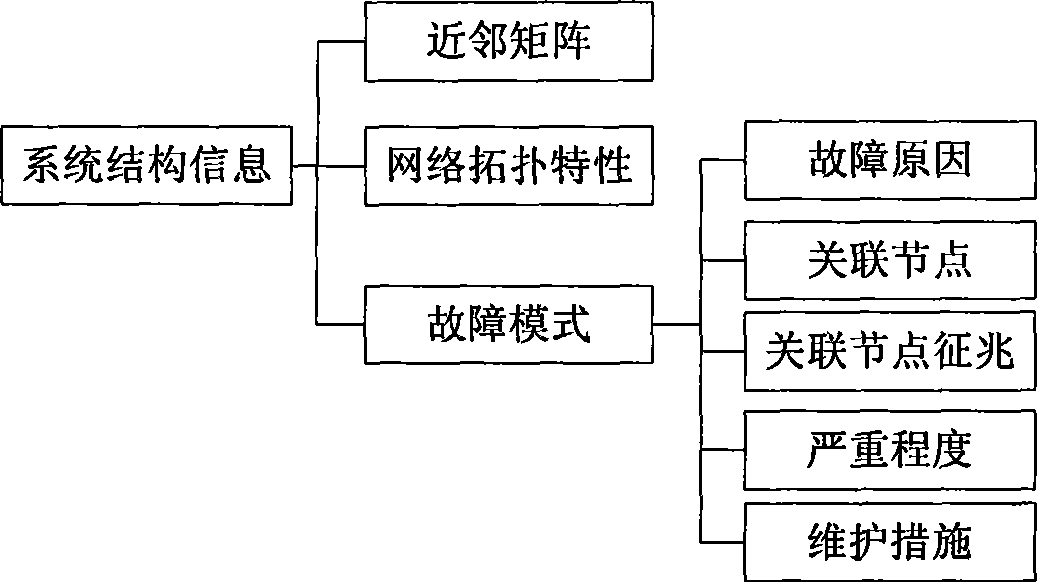

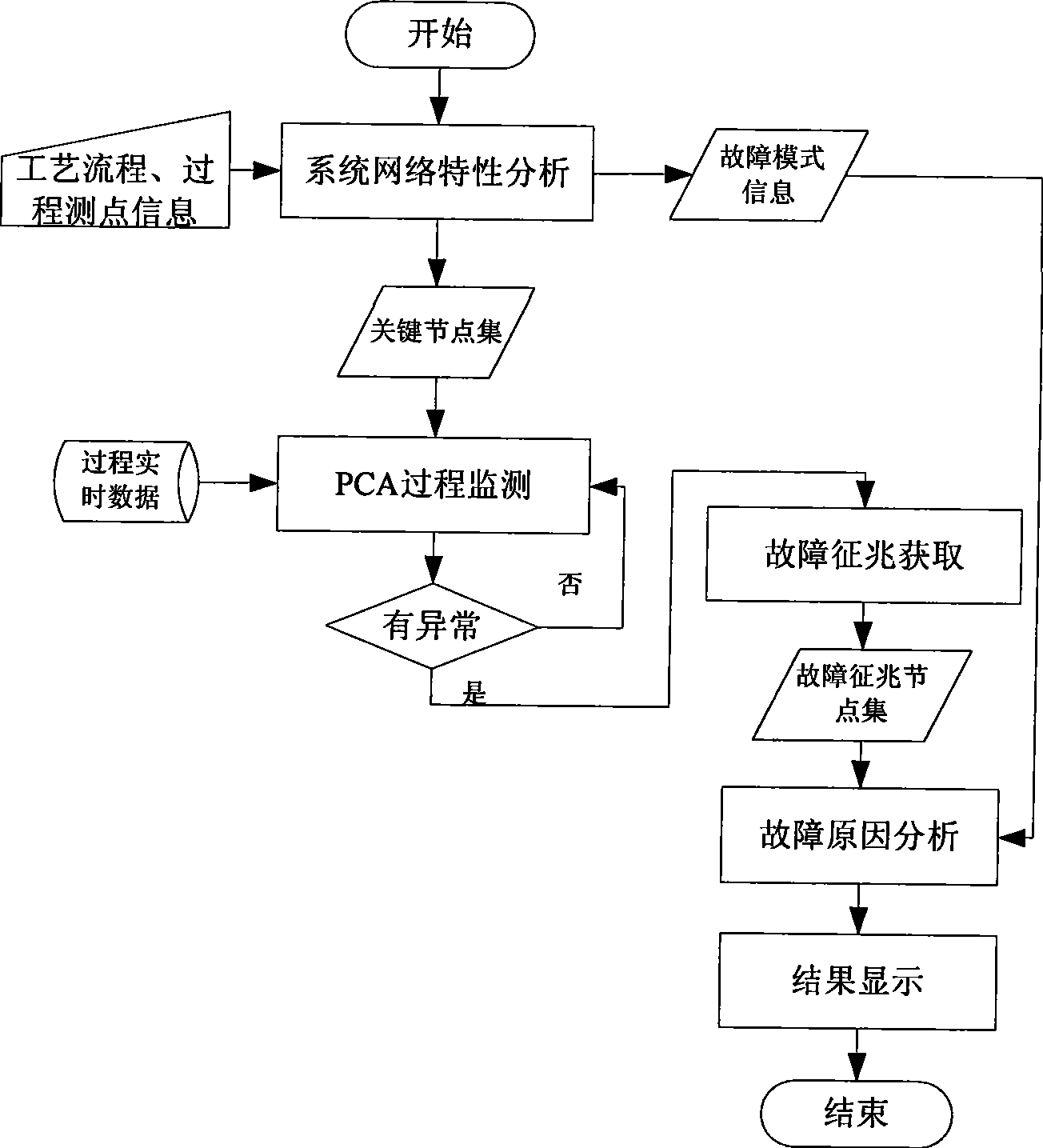

Method used

Image

Examples

Embodiment Construction

[0036] First, the concepts of complex network theory, network topology characteristics, and node correlation strength involved in the present invention are briefly introduced and defined as follows:

[0037]Principal component analysis (PCA): referred to as PCA, is a technique commonly used in process monitoring. The process of reducing the dimensionality of a data set composed of correlated variables to obtain characteristic signals (pivot signals) that are not correlated with each other, that is, using less dimensional principal component signals to represent the dynamic changes of the process data matrix. It constructs the process statistic T based on the process principal component feature signal subspace information 2 And the statistic Q of residual information subspace information, determine its control limit, and then realize the process of process monitoring. When system abnormalities are detected, fault variables are identified by constructing contribution graphs or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com