Method for model mismatching detection and positioning of multivariate predictive control system in chemical process

A technology for predictive control and chemical process, applied in the field of fault diagnosis of process industrial control systems, it can solve problems such as complex and large systems, and achieve the effects of reducing interference, reducing maintenance costs, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] The specific embodiment of the present invention will be further described below with regard to the solvent recovery process of a refined terephthalic acid (PTA) plant in a domestic factory as an example.

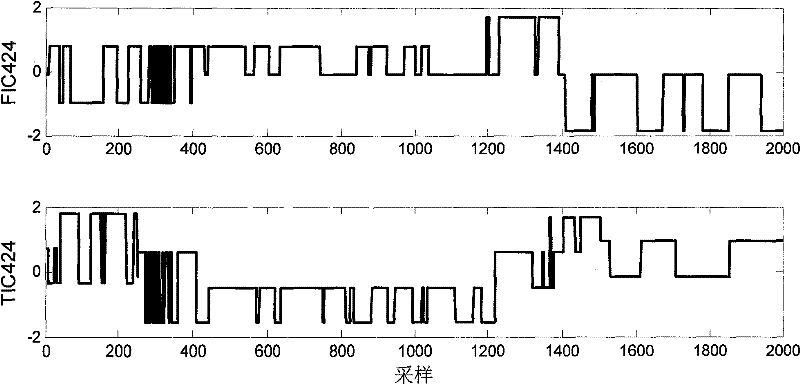

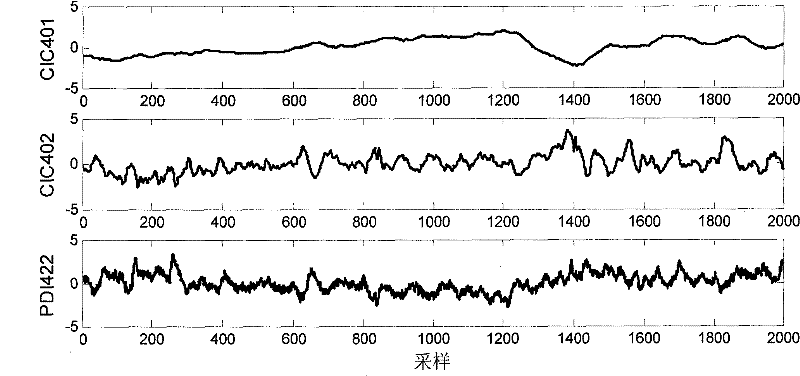

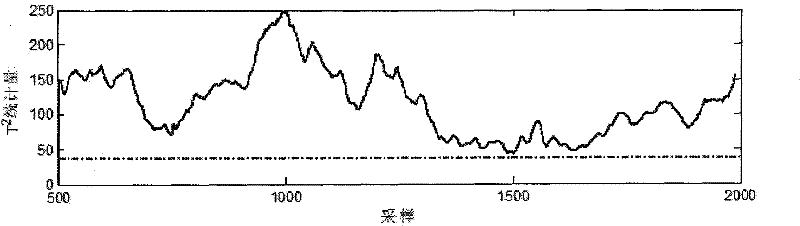

[0065] The solvent recovery process of the PTA unit, the flow chart is as follows figure 2 shown. The solvent recovery tower T403 uses a mixture of acetic acid and water as raw materials; the liquid phase at the bottom of the tower is heated by the reboiler E403 and then returned to the tower, and the extracted acetic acid at the bottom of the tower is returned to the PTA device for recycling; the gas phase at the top of the tower passes through the condenser E404 and enters reflux Tank D404, part of which is returned to the tower as reflux, and the rest of the waste water is discharged. Among them, the heating amount of steam at the bottom of the tower FIC424 and the temperature of the bottom of the tower TIC424 form a PID cascade loop. In the MPC controller, TIC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com