Method for separating and purifying salvianolic acid from red sage root liquid extract by one step

A technology of separation and purification and water extraction, which is applied in the separation/purification of carboxylic acid compounds, medical preparations containing active ingredients, organic chemistry, etc. It can solve the problems of unreported parameters such as purity and yield, and unclear structure-activity relationship. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

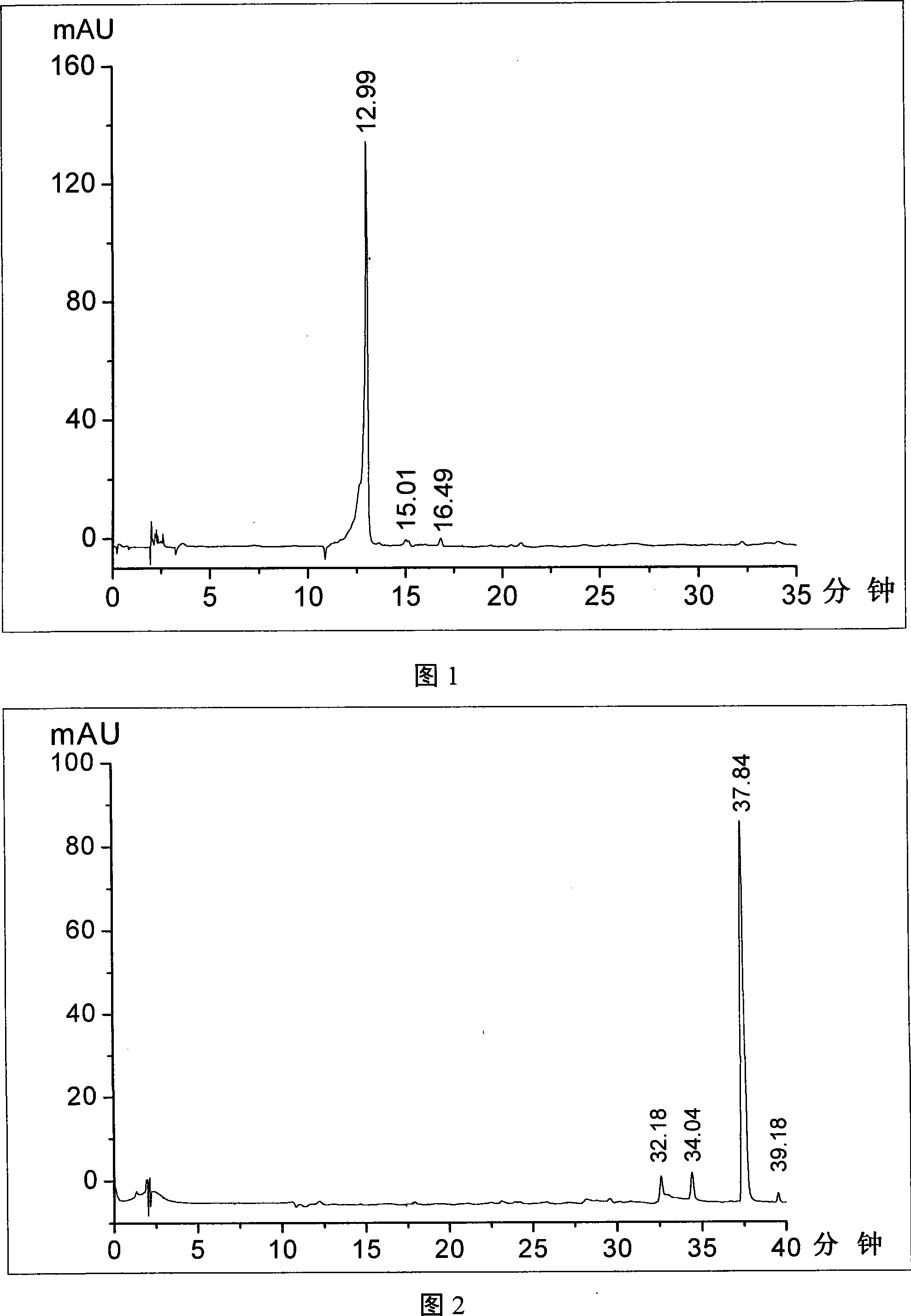

Image

Examples

Embodiment 1

[0027] (1) Water extraction and alcohol precipitation: Take Danshen medicinal material and crush it to 20-35 meshes, extract with 15 times of water, add 95% ethanol to make the ethanol volume content in the extract reach 60%, refrigerate at 4°C for 24 hours, and then centrifuge. 5500 revolutions per minute, recover the supernatant, and spin-steam until ethanol-free to obtain the water-extracted ethanol-precipitated liquid of Salvia miltiorrhiza.

[0028] (2) Acidification and salt addition: Take 200 milliliters of the water-extracted alcohol sedimentation solution and adjust the pH to 3.5 with 4% hydrochloric acid (mass concentration), remove the flocculent precipitate by centrifugal filtration, and add 4 g of sodium chloride at a rotating speed of 5500 rpm.

[0029] (3) Loading and elution: the above-mentioned extracted solution flows through a resin with a diameter of 19 mm at a flow rate of 1.33 times the volume of the resin per hour at 25°C, with a length-to-diameter ratio ...

Embodiment 2

[0033] (1) Water extraction: take Danshen medicinal material and crush to 20-35 mesh, and extract with 15 times of water.

[0034] (2) Acidification and salt addition: take 200 ml of water extract and adjust the pH to 3.5 with 4% hydrochloric acid (mass concentration), centrifuge and filter to remove flocculent precipitates, the rotating speed is 5500 rpm, and then add 4g of sodium chloride.

[0035] (3) Loading and elution: the above-mentioned extracted solution flows through a resin with a diameter of 19 mm at a flow rate of 1.33 times the volume of the resin per hour at 25°C, with a length-to-diameter ratio of 1:10, and filled with weakly polar large resins. Pore adsorption resin SP825 chromatographic column for dynamic adsorption; after loading the sample, use 250 milliliters of distilled water to carry out dynamic elution with a flow rate of 1.33 times the resin volume / hour, and collect the water eluate; then use distilled water and 95% ethanol The mixed solution (the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com