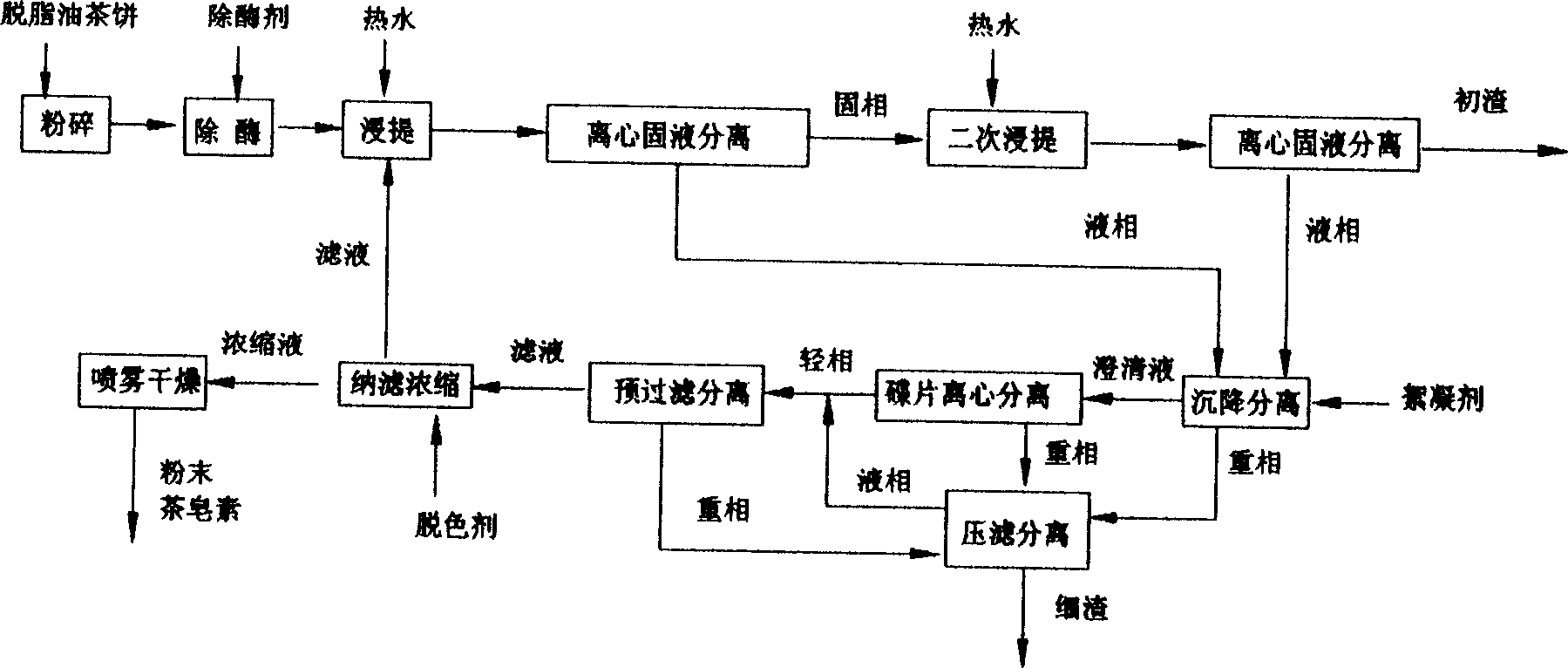

Production process for extracting tea saponin from tea-oil tree cake by using water as dissoluent

A technology of camellia oil cake and production method, which is applied in the field of tea saponin extraction, can solve the problem of not realizing the industrialized production of tea saponin by water extraction, and achieves the effects of close energy consumption and flux, improved product purity, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take by weighing 6kg of degreased camellia seed cake, pulverize with a pulverizer, suppress and eliminate the activity of hydrolase in the tea meal powder by chemical treatment, that is, add 0.3% sodium benzyl and 0.5% tea meal weight 0.5% sodium benzyl in the tea meal powder Sodium carbonate, soaked with 12kg of tap water at a temperature of 45°C for 1.5 hours; after the three-legged centrifuge separated the leaching solution, the residue was soaked once according to the above method, and a total of 23.2kg of the filtrate was obtained; the filtrate was introduced into the sedimentation tank and added 90g Flocculant (50% alum, 40% polychitosan, 10% ferric chloride), after stirring evenly, let it stand for 1 hour; 23.0Kg of clarified liquid passed through disc separator, and after 10 minutes, light phase and heavy phase were obtained The heavy phase is passed through the filter press, and the filtrate is merged into the light phase to obtain a total of 22.2kg of clarified...

Embodiment 2

[0032] Weigh 10kg of camellia seed cake, pulverize it with a pulverizer, suppress and eliminate the activity of hydrolase in the tea meal powder by chemical treatment, that is, add 0.3% sodium benzyl and 0.5% sodium carbonate to the tea meal powder Soak 2.0 hours with 20kg of tap water at 40°C in temperature; after the three-legged centrifuge separates the extract, soak the residue once by the above-mentioned method, and obtain a total of 38.7kg of filtrate; % alum, 40% polychitosan, 10% ferric chloride), leave standstill for 1 hour; 38.3Kg clarified liquid passes through disc separator, and after 17 minutes, light phase and heavy phase are obtained; light phase is passed through pre-filter , the heavy phase passes through the filter press, and the filtrate is merged into the light phase to obtain a total of 36.9kg of clarified extract (tea saponin solution) and 1.4kg of fine residue. Nanofiltration membrane area is 2m 2 , the molecular weight cut-off is 1000 according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com