Digital printing process for real silk fabric

A technology for silk fabrics and digital printing, applied in textiles, papermaking, dyeing and other directions, can solve the problems of the digital printing process failing to achieve the expected results, and achieve the effect of maintaining color and vividness, improving color depth and reducing color difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

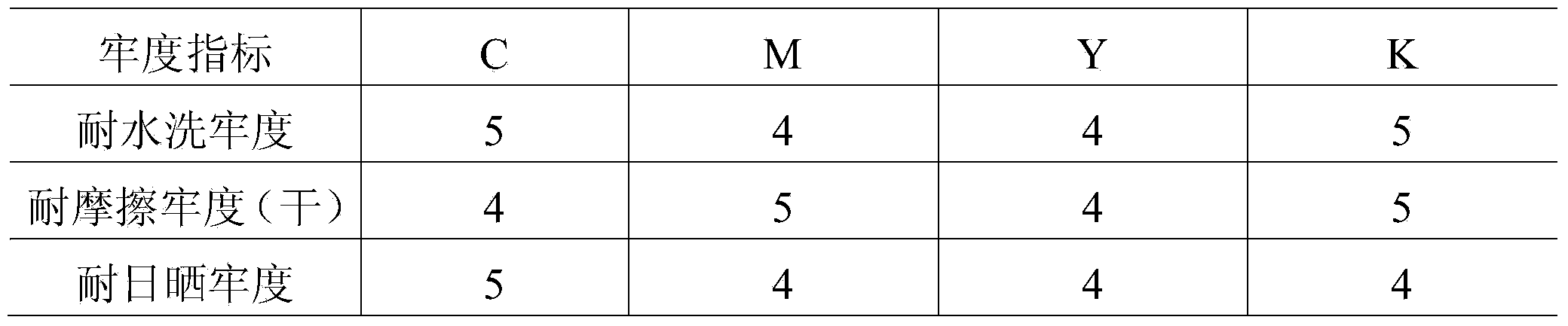

Embodiment 1

[0024] A digital printing process for silk fabrics, comprising the following steps: silk fabric → low-temperature plasma treatment → padding pretreatment liquid → drying → inkjet printing → drying → dry heat color fixing → cold water washing → warm water washing → soaping → warm water washing → drying, the content of each component of the pretreatment liquid in the padding pretreatment liquid is as follows: sodium alginate 7g / L, baking soda 40g / L, urea is 40g / L, defoamer 10g / L.

[0025] Wherein, in the low-temperature plasma treatment step, a discharge plasma treatment device is used to modify the surface of the silk fabric. The discharge plasma treatment device includes two discharge electrodes, which are embedded in a barrier medium, and the distance between the plates is 5 cm. The discharge plasma treatment device uses O 2 It is the plasma working gas, the processing power is 60W, the silk fabric is placed between the two electrode plates, not in contact with the two ele...

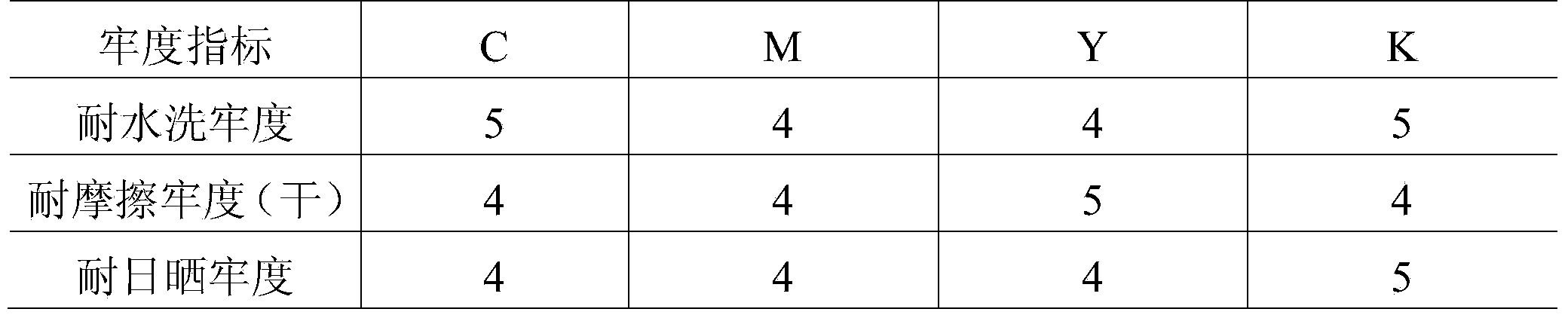

Embodiment 2

[0033] A digital printing process for silk fabrics, comprising the following steps: silk fabric → low-temperature plasma treatment → padding pretreatment liquid → drying → inkjet printing → drying → dry heat color fixing → cold water washing → warm water washing → soaping → warm water washing → drying, the content of each component of the pretreatment liquid in the padding pretreatment liquid is as follows: sodium alginate 5g / L, baking soda 50g / L, urea is 30g / L, defoamer 5g / L.

[0034] Wherein, in the low-temperature plasma treatment step, a discharge plasma treatment device is used to modify the surface of the silk fabric. The discharge plasma treatment device includes two discharge electrodes embedded in a barrier medium, and the distance between the plates is 3 cm. The discharge plasma treatment device uses O 2 It is the plasma working gas, the processing power is 50W, the silk fabric is placed between the two electrode plates, not in contact with the two electrode plate...

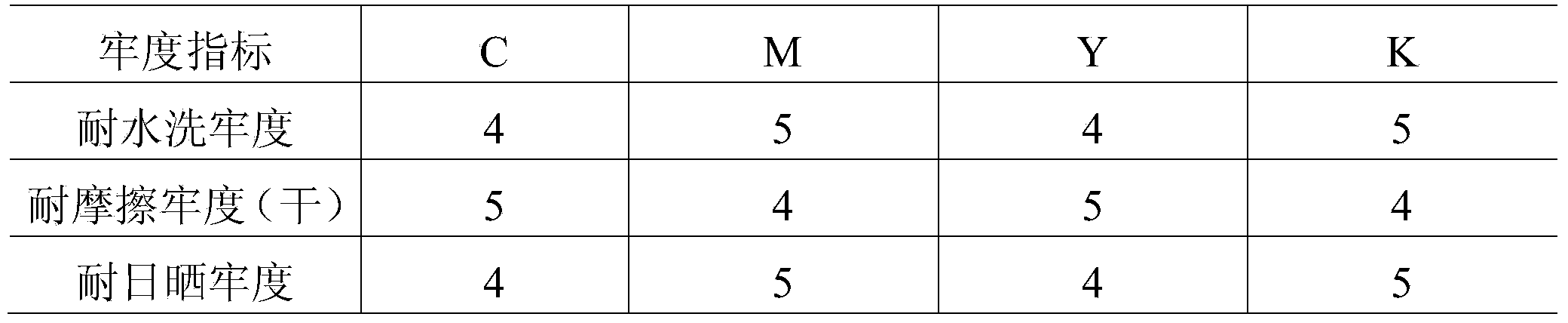

Embodiment 3

[0042]A digital printing process for silk fabrics, including the following steps: silk fabric → low-temperature plasma treatment → padding pretreatment solution → drying → inkjet printing → drying → dry heat color fixing → cold water washing → warm water washing → soaping → Warm water washing → drying, the content of each component of the pretreatment liquid in the padding pretreatment liquid is as follows: sodium alginate 10g / L, baking soda 30g / L, urea is 50g / L, defoamer 15g / L.

[0043] Wherein, in the low-temperature plasma treatment step, a discharge plasma treatment device is used to modify the surface of the silk fabric. The discharge plasma treatment device includes two discharge electrodes, which are embedded in a barrier medium, and the distance between the plates is 10 cm. The discharge plasma treatment device uses O 2 It is the plasma working gas, the processing power is 70W, the silk fabric is placed between the two electrode plates, not in contact with the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com