Environment-friendly silk printing method

A pure silk and environmentally friendly technology, applied in dyeing, biochemical fiber treatment, textiles and papermaking, etc., to achieve the effect of bright printing colors, less energy consumption, and good K/S value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Fabric enzyme pretreatment: Put the degummed and tentered silk fabric into the enzyme solution for pretreatment. The enzyme treatment process conditions are: papain 15U / mL, cellulase 3U / mL, pH7, temperature 40°C, time 1h, liquor ratio 1:10, wash with water and air dry after treatment;

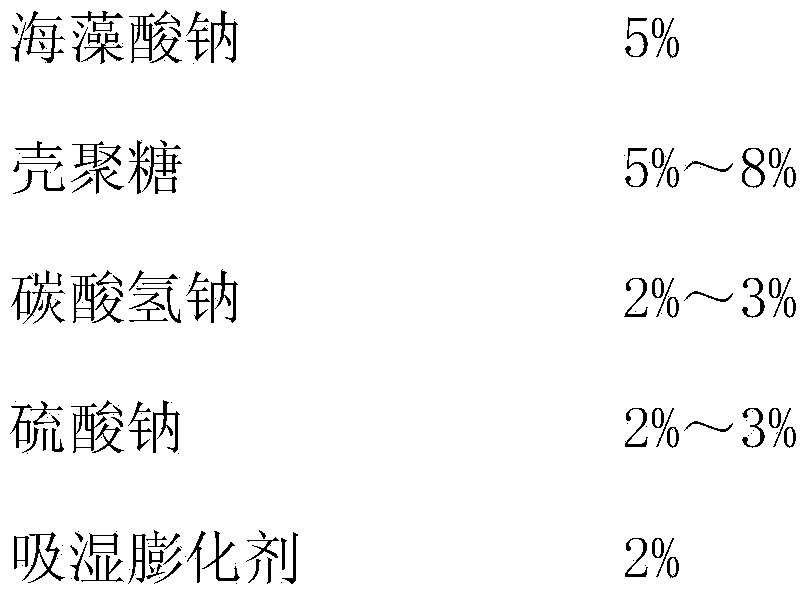

[0032] (2) Sizing: the real silk fabric after enzyme pretreatment is sizing on one side on a sizing machine, and its size is composed as follows by weight percentage:

[0033]

[0034] The remainder is water;

[0035] The hygroscopic swelling agent is that the mass ratio of urea to triethylene glycol is 3:7

[0036] (3) Drying: Infrared drying equipment is used, the drying temperature is 100°C, and the drying time is 5 minutes;

[0037] (4) Making documents: the above-mentioned jet printing is generated by the color card software, the printing conditions are: printing precision 360×2160dpi, 360×2160 6pass CMYK, the ink used for jet printing is regenerative reactive dye ink;

[...

Embodiment 2

[0050] (1) Fabric enzyme pretreatment: Put the degummed and tentered silk fabric into the enzyme solution for pretreatment. The enzyme treatment process conditions are: papain 16U / mL, cellulase 4U / mL, pH7, temperature 40°C, time 1h, liquor ratio 1:10, wash with water and air dry after treatment;

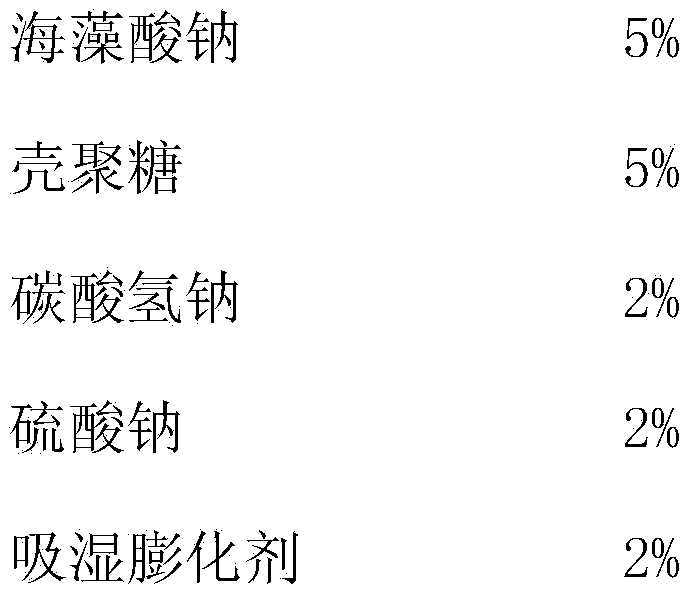

[0051] (2) Sizing: the real silk fabric after enzyme pretreatment is sizing on one side on a sizing machine, and its size is composed as follows by weight percentage:

[0052]

[0053] The remainder is water;

[0054] The hygroscopic swelling agent is that the mass ratio of urea to triethylene glycol is 2:8

[0055] (3) Drying: Infrared drying equipment is used, the drying temperature is 100°C, and the drying time is 5 minutes;

[0056] (4) Making documents: the above-mentioned jet printing is generated by the color card software, the printing conditions are: printing precision 360×2160dpi, 360×2160 6pass CMYK, the ink used for jet printing is regenerative reactive dye ink;

[...

Embodiment 3

[0069] (1) Fabric enzyme pretreatment: Put the degummed and tentered silk fabric into the enzyme solution for pretreatment. The enzyme treatment process conditions are: papain 17U / mL, cellulase 5U / mL, pH7, temperature 40°C, time 1h, liquor ratio 1:10, wash with water and air dry after treatment;

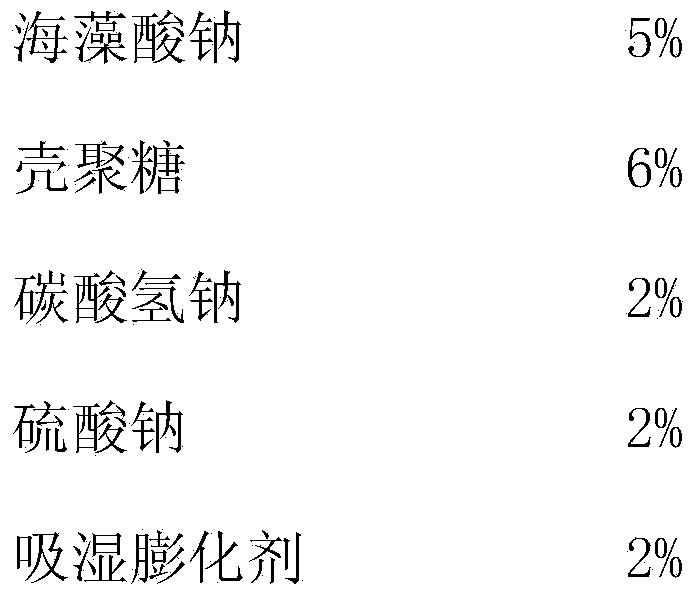

[0070] (2) Sizing: the real silk fabric after enzyme pretreatment is sizing on one side on a sizing machine, and its size is composed as follows by weight percentage:

[0071]

[0072] The remainder is water;

[0073] The hygroscopic swelling agent is that the mass ratio of urea to triethylene glycol is 4:6

[0074] (3) Drying: Infrared drying equipment is used, the drying temperature is 100°C, and the drying time is 5 minutes;

[0075] (4) Making documents: the above-mentioned jet printing is generated by the color card software, the printing conditions are: printing precision 360×2160dpi, 360×2160 6pass CMYK, the ink used for jet printing is regenerative reactive dye ink;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com