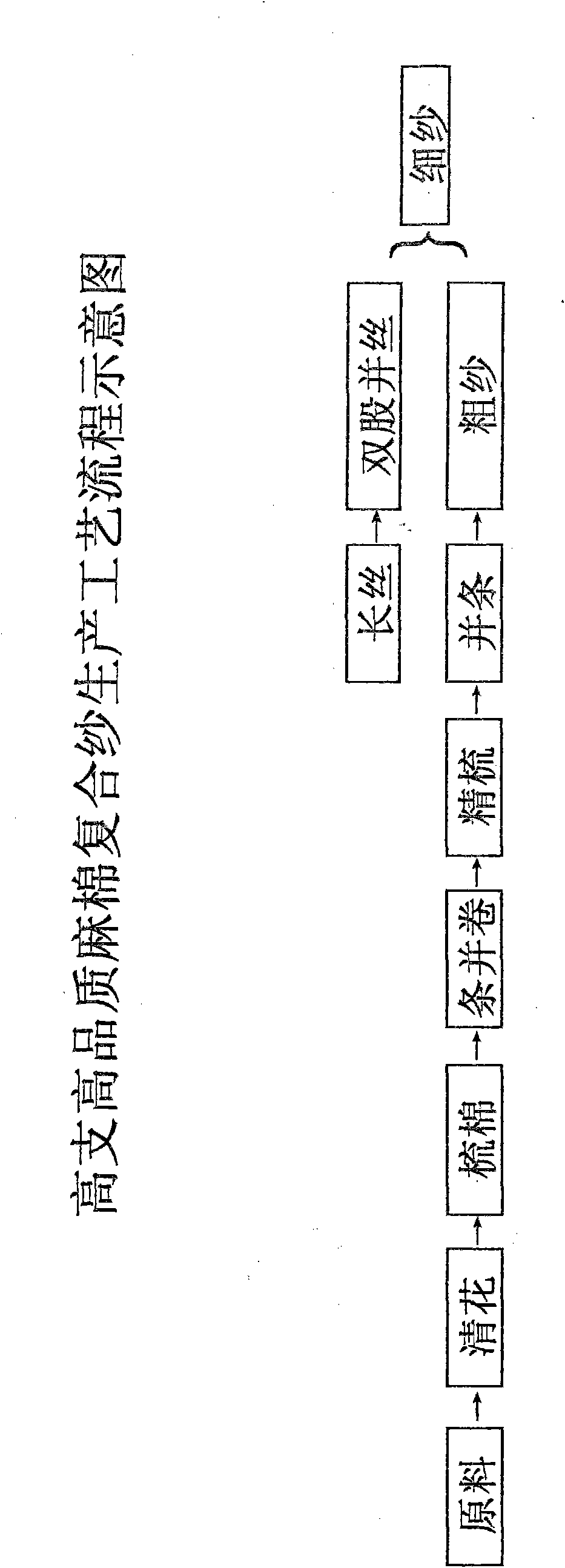

Technology for processing embedded high count high-quality ramie cotton blending yarns

A processing technology and embedded technology, which is applied in the direction of yarn, spinning machine, textile and papermaking, etc., to achieve the effect of reducing procedures, reducing costs, and achieving remarkable economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

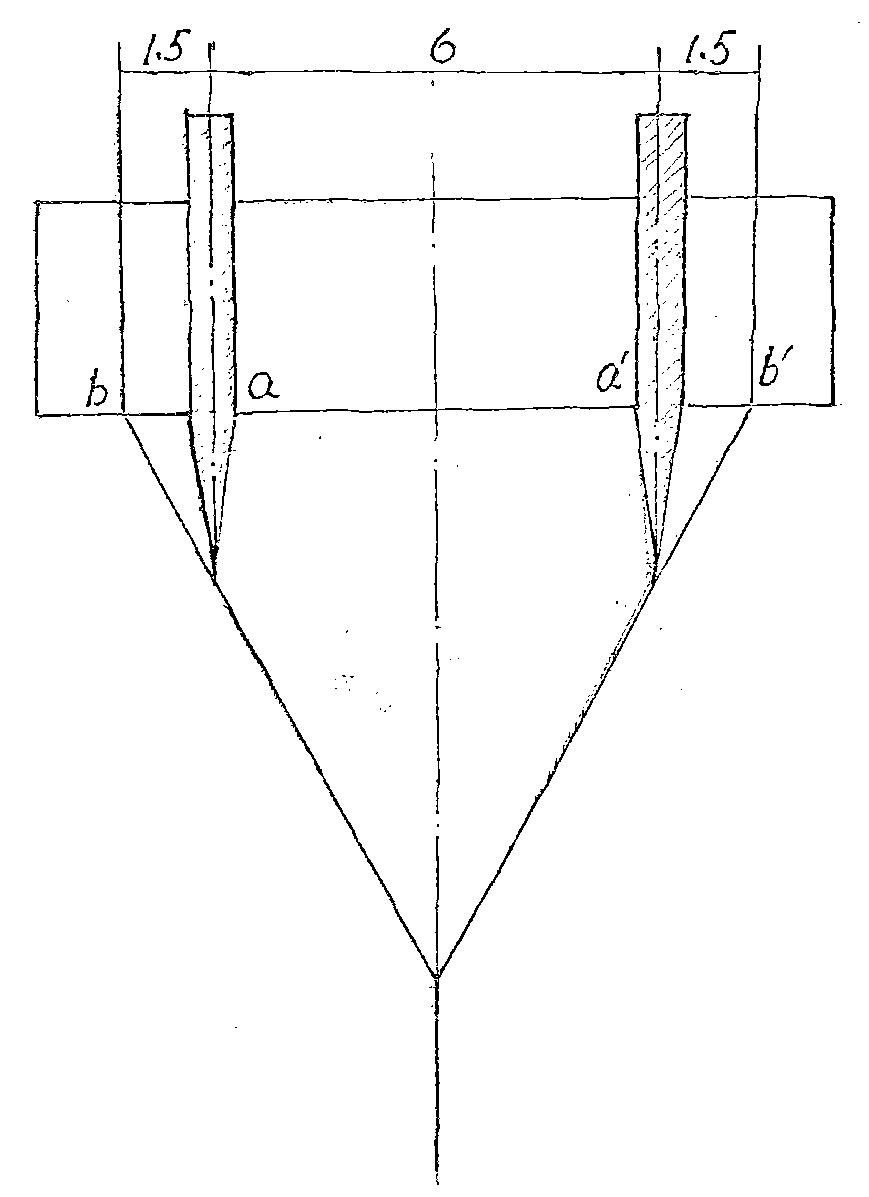

[0032] Embodiment 1 spinning fully combed 100S / 2 flax / modal / cotton (25 / 35 / 40) composite yarn

[0033] Yarn composition Feed rovings: two 25% linen and 35% modal blended rovings

[0034] Feed filament: two 60% cotton and 40% modal blended JC160S yarns

[0035] The relative positions of two filaments and two rovings: the two filaments are located outside the two rovings, the distance between the two rovings is 6mm, which is determined by the yarn guide horn, and the distance between the filament and the center of the roving is 1.5mm, so the two filaments The spacing is 9mm, so it is necessary to adjust the distance between the two guide grooves of the pair of guide wheels on the double-strand filament positioning wire feeding device to be 9mm, and feed the two filaments into a pair of guide grooves in parallel In the groove, after being positioned by the wire guide groove, it is fed into the rear end of the front roller of the spinning frame in parallel. The front nip composed...

Embodiment 2

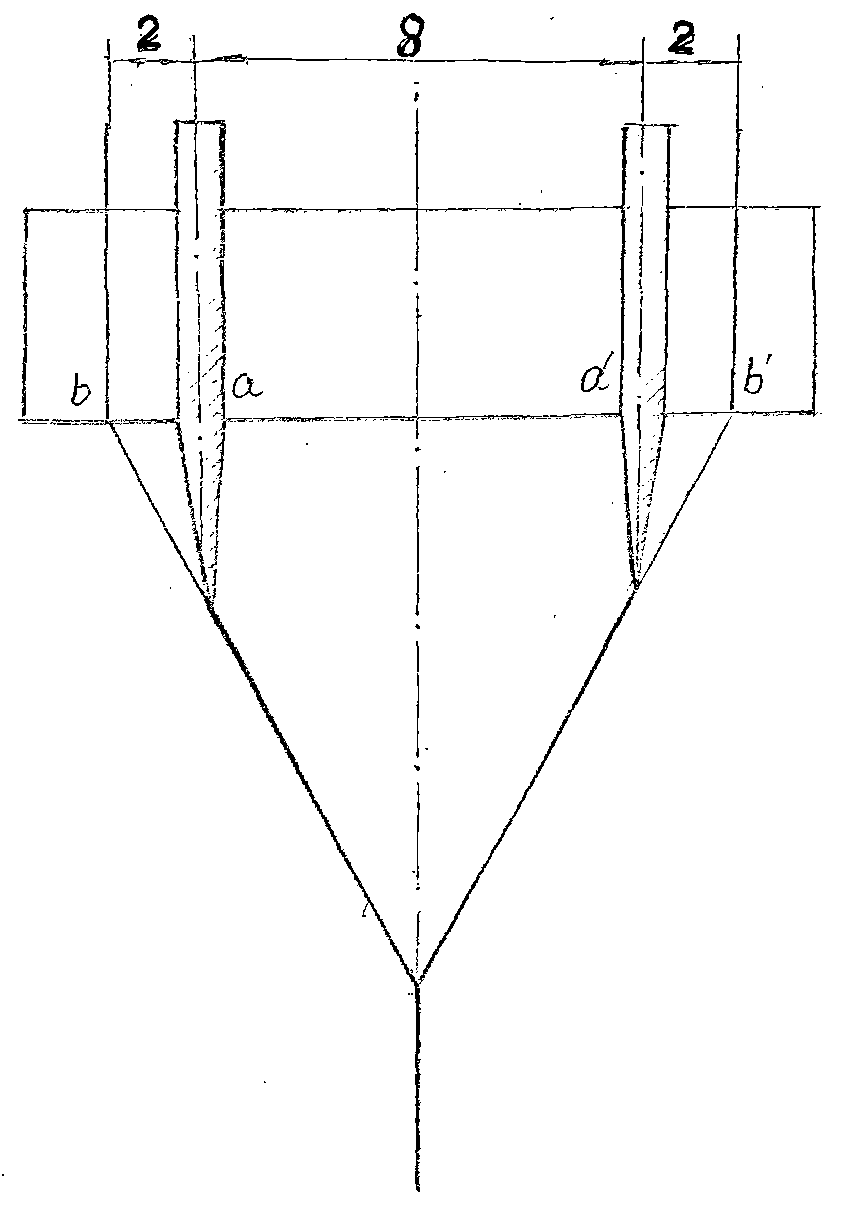

[0036] Embodiment 2 spinning fully combed 80S / 2 ramie, cotton (25 / 75) composite yarn

[0037] Yarn composition Feed rovings: two 25% ramie and 75 cotton blended rovings

[0038] Feed filament: two 100% cotton JC100S

[0039] The relative positions of two filaments and two rovings: two filaments are located outside the two rovings, the distance between the two rovings is 8mm, which is determined by the yarn guide horn, and the center distance between the roving and the filaments is 2mm, then the center distance between the two filaments is 12mm, adjust the distance between the guide wire grooves of the pair of wire guide wheels of the double-strand filament positioning guide wire feeding device to be 12mm. The operation method of spinning composite yarn is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com