Method for reducing resultant yarn filoplume

A yarn-forming and yarn-forming technology, applied in the field of textile processing, can solve the problem that the processing quality is not substantially improved, and achieve the effects of reducing the hairiness of the winding yarn, facilitating large-scale popularization and application, and reducing the energy consumption of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

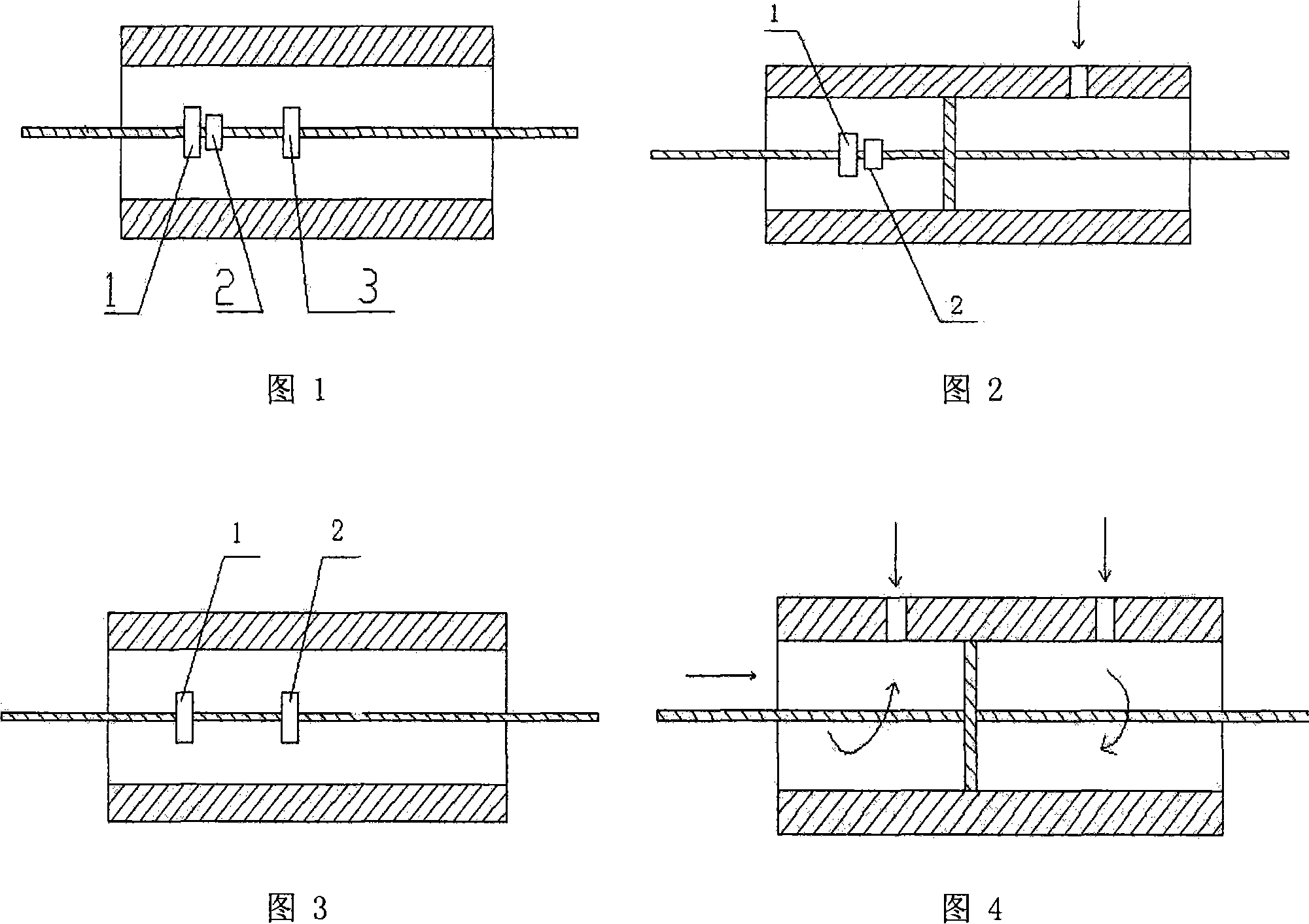

[0025] See Attachment 1

[0026] The yarn hairiness reduction device with untwisting heating adopts mechanical twisting and untwisting, heater heating, and mechanical twisting and twisting.

[0027] In Fig. 1, 1 is a mechanical twister, 2 is a heating device, and 3 is a mechanical twister. The movement direction of the twister 1 is opposite to the twisting direction of the yarn, and the reverse force is applied to the yarn to untwist the fibers on the surface of the yarn; the untwisted fiber strands immediately enter the heating device 2 for heating; the heated fiber strands The strands pass through the twister 3, and the movement direction of the twister 3 is the same as the twisting direction of the yarn, and the force in the same direction is applied to the yarn, so that the heated fiber strands are twisted into yarns.

Embodiment 2

[0029] See Attachment 2

[0030] In Fig. 2, the yarn hairiness reduction device for untwisting heating adopts mechanical twisting and untwisting, heater heating, and air-flow twisting.

[0031] In the figure, 1 is a mechanical twister, and 2 is a heating device. The direction of movement of the twister 1 is opposite to the twist direction of the yarn, and the reverse force is applied to the yarn to untwist the fibers on the surface of the yarn; the untwisted fibers The strands immediately enter the heating device 2 for heating; the heated fiber strands enter the twisting work area separated by the partition, and the tube wall of this area has a row of holes through the wall of the device cavity according to a certain arrangement. When the air flow is passed through, a vortex in the same twist direction as the yarn can be formed inside the device, and twisted into yarn.

Embodiment 3

[0033] See Attachment 3

[0034] The yarn hairiness reduction device with untwisting heating adopts a heatable mechanical twisting untwisting and heating, mechanical twisting and twisting method.

[0035] In the figure, 1 is a mechanical twister, which can heat the yarn at the same time, and 2 is a mechanical twister. The direction of movement of the twister 1 is opposite to the twisting direction of the yarn, and the reverse force is applied to the yarn to untwist the fibers on the surface of the yarn, and at the same time heat the fibers; the heated fiber strands pass through the twister 2 , The movement direction of the twister 2 is the same as the twist direction of the yarn, and the yarn is given the same force to make the heated fiber strands twisted into yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com