Cloth clipping and conveying device for textile processing

A conveying device and fabric conveying technology, which is applied in the cutting, transportation and packaging of textile materials, textiles and paper making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

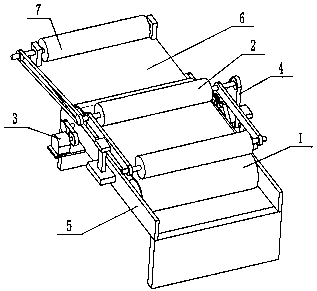

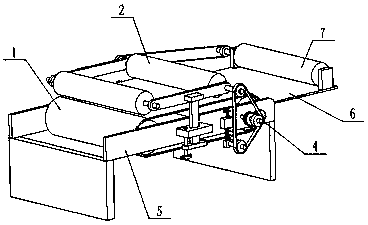

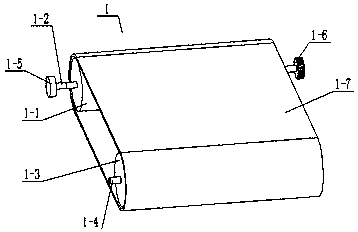

[0029] Such as Figure 1-11As shown, a cloth cutting and conveying device for textile processing includes a cloth conveying mechanism 1, a lifting and lowering cloth roller mechanism 2, a driving mechanism 3, a tensioning transmission mechanism 4, a frame 5, a cutting table 6 and a cloth delivery roller mechanism 7 , the cloth conveying mechanism 1 is connected to the inner side of the frame 5; the lifting press roller mechanism 2 is arranged on the upper end of the cloth conveying mechanism 1, and both sides of the bottom end of the lifting press roller mechanism 2 are respectively connected to the frame 5 in the middle of both ends; the drive mechanism 3 is fixedly connected to the left end of the frame 5, and the drive mechanism 3 is connected to the cloth conveying mechanism 1; the tension transmission mechanism 4 is fixedly connected to the right end of the frame 5, and the cloth conveying mechanism 1 passes through The tension transmission mechanism 4 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com