Preparation method of liquid crystal microcapsule for textile printing

A technology of microcapsules and textiles, which is applied in the fields of fine chemicals and materials science, can solve problems affecting the clarity and color of cholesteric liquid crystals, unsuitable application of capsule wall materials, and shortening the service life of liquid crystals, so as to meet the needs of clothing personalization and Requirements for diversity, bright color, narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

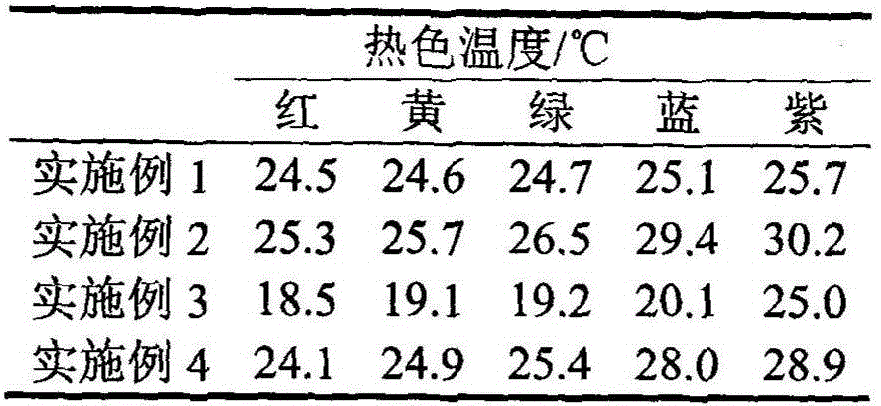

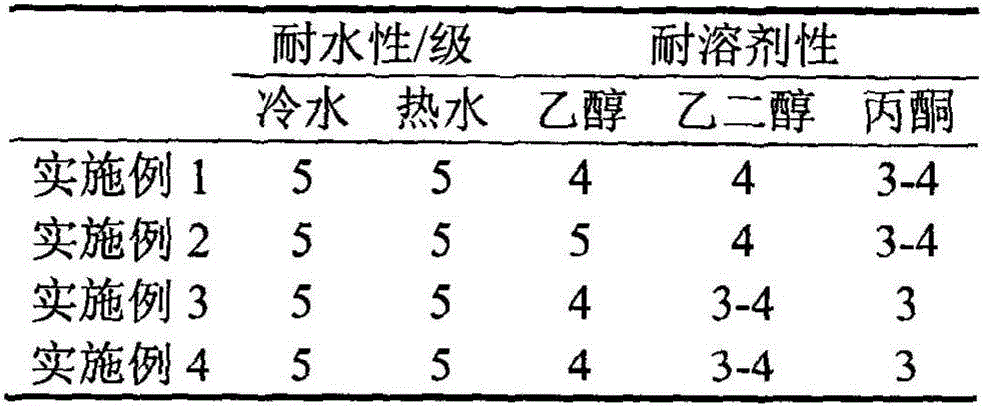

Embodiment 1

[0018] Mix 3g of cholesteryl nonanoate and 7g of cholesteryl oleyl carbonate and heat until they are completely dissolved and become transparent. After stirring at this temperature for 2 hours, cool down until the mixed liquid crystal appears color or turbid, and then heat up to just transparent. The temperature is the clearing point of the mixed liquid crystal, and stirred at constant temperature for 4 hours to obtain the mixed liquid crystal.

[0019] 2.5g sodium dodecylbenzene sulfonate is dissolved in 72.5g deionized water, be warmed up to the clearing point temperature of mixed liquid crystal, drop mixed liquid crystal thereinto under mechanical stirring, high-speed emulsification forms uniform liquid crystal dispersion; 2.5 1 g of n-butyl acrylate and 2.5 g of methyl methacrylate were evenly mixed and added dropwise to the liquid crystal dispersion, and the emulsification was continued for 60 minutes. Then transferred to a four-necked flask with condensing reflux and sti...

Embodiment 2

[0021] Mix 1g of cholesteryl propionate, 1.5g of cholesteryl oleate, 2g of cholesteryl benzoate, and 0.5g of cholesteryl ethyl carbonate and heat until they are completely dissolved. Stir at this temperature for 3 hours, then cool down to the mixing After the color or turbidity of the liquid crystal appears, the temperature is raised until it is just transparent. This temperature is the clearing point of the mixed liquid crystal. Stir at constant temperature for 5 hours to obtain the mixed liquid crystal.

[0022] Dissolve 0.5g OP-10 in 79.5g deionized water, heat up to the temperature of the clearing point of the mixed liquid crystal, add the mixed liquid crystal dropwise under the action of mechanical stirring, and emulsify at high speed to form a uniform liquid crystal dispersion; mix 2g styrene and 3g acrylic acid Ethyl ester was added dropwise to the liquid crystal dispersion after uniform mixing, and then added dropwise to the liquid crystal dispersion, and the emulsifica...

Embodiment 3

[0024] Mix 5g of cholesteryl carbonate, 8g of cholesteryl oleate, and 2g of cholesteryl chloride and heat until they are completely dissolved. After stirring for 3 hours at this temperature, cool down until the color or turbidity of the mixed liquid crystal appears, and then heat up to just Transparent, this temperature is the clearing point of the mixed liquid crystal, stirring at constant temperature for 5 hours, the mixed liquid crystal is obtained.

[0025]Dissolve 7.5g DNS-86 in 58.5g deionized water, heat up to the temperature of the clearing point of the mixed liquid crystal, add the mixed liquid crystal dropwise under the action of mechanical stirring, and emulsify at high speed to form a uniform liquid crystal dispersion; After the ester and 6 g of isoprene were mixed evenly, they were added dropwise to the liquid crystal dispersion, and the emulsification was continued for 45 minutes. Then transferred to a four-necked flask with condensing reflux and stirring device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com