Three-axis symmetrical composite spinning process and equipment for high-elasticity composite yarn

A technology of composite spinning and composite yarn, which is applied in the direction of spinning machine, drafting equipment, yarn, etc., can solve problems such as loss of elasticity, unstable structure, and inability to be used for high elastic requirements, and achieve high elastic yarn structure, Simple method, anti-wrinkle and shape-stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

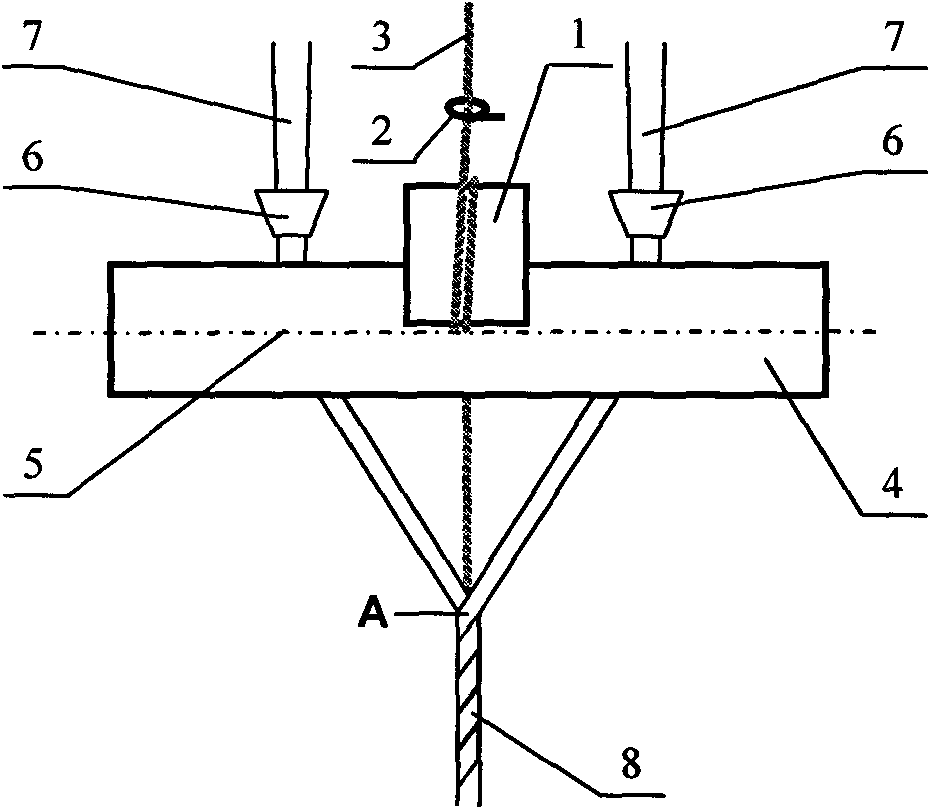

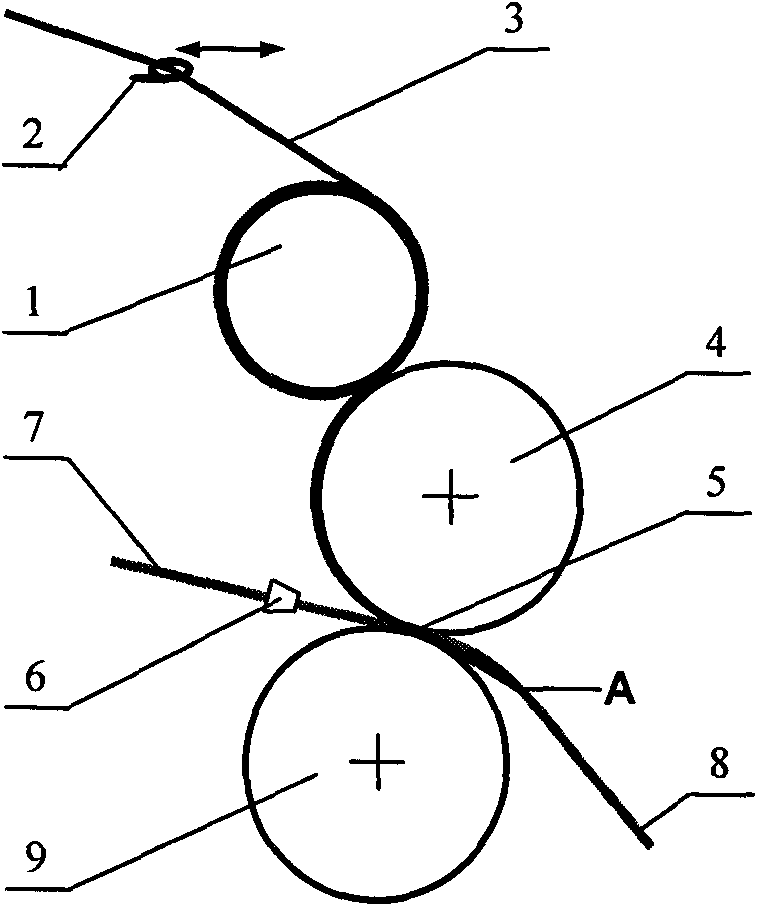

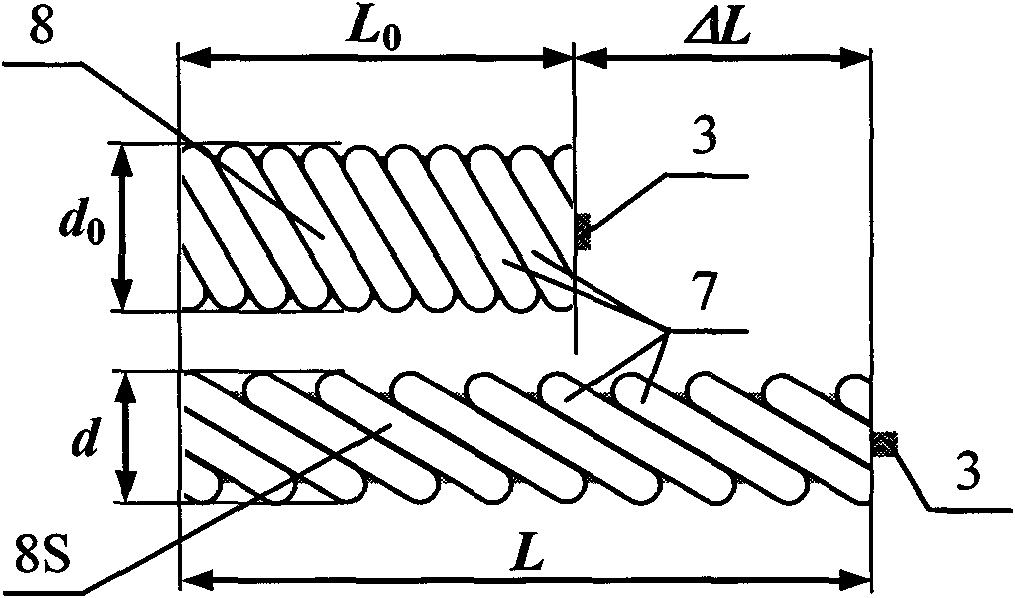

[0034] Embodiment 1: Spinning the high-elastic composite yarn of cotton covering spandex filament

[0035] Choose two cylinders of cotton roving sliver and one cylinder of spandex yarn as the raw material of composite spinning, the raw material ratio of triaxial system is: the mass ratio of cotton / cotton / spandex filament is 40 / 40 / 20, utilize composite spinning process of the present invention spinning. Spandex filaments are held with a wrapping angle of 120° and zero additional turns, fed from the central axis with a tension of 10cN; cotton slivers are symmetrically synchronized from the other two axes at a distance of 10mm by the natural tension of spinning and drafting After feeding, the three will converge at point A under the action of 150 twist / 10cm twist (wrapping angle is about 58°) after exiting the nip of the front roller, forming spandex yarn wrapped symmetrically by two bundles of cotton whiskers , High elastic composite yarn with stable structure, its elastic elon...

Embodiment 2

[0036] Embodiment 2: Spinning spun silk to cover Lycra composite yarn

[0037] Choose two cylinders of spun silk roving strips and a cylinder of Lycra silk as the raw material of composite spinning, the raw material ratio of triaxial system is: the mass ratio of silk silk / spun silk / Lycra silk is 36 / 36 / 28, utilizes the composite spinning of the present invention Spinning process spinning. Lycra yarn's gripping roller has an enveloping angle of 100° and the number of winding turns is zero. It is fed from the central axis with a tension of 2cN; the silk filaments are synchronized from the other two axes at a distance of 8mm by the natural tension of spinning and drafting. Symmetrical feeding, the three are converged at point A under the action of 140 twist / 10cm twisting (wrapping angle is about 46°) after exiting the nip of the front roller, forming Lycra silk wrapped symmetrically by two bundles of silk strands The inner and structurally stable high-elastic composite yarn has a...

Embodiment 3

[0038] Embodiment 3: Spinning cotton and linen blended coated spandex filament composite yarn

[0039] Select two tubes of cotton-linen blended roving sliver and one tube of spandex yarn as raw materials for composite spinning. The ratio of the raw materials of the triaxial system is: the mass ratio of cotton-linen blended / cotton-linen blended / spandex yarn is 42 / 42 / 16. Invented composite spinning process spinning. The gripping roller of spandex yarn has an enveloping angle of 80° and one additional turn, that is, the enveloping angle is 80°+360°, fed from the central axis, and the tension is 20cN; Feed synchronously and symmetrically from the other two axes at a distance of 10mm. After the three are out of the nip of the front roller, they converge at point A under the action of twisting of 180 twists / 10cm (the wrapping angle is about 62°) to form a spandex quilt. Two bundles of cotton and linen blended yarns are symmetrically wrapped inside, and the structurally stable high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com