Ring spun sectional-color yarn and preparing method and device thereof

A technology of ring spinning and segmental coloring, which is applied to spinning machines, textiles, papermaking, and drafting equipment, etc. It can solve problems such as large drafting multiples in the front area, inability to correctly control segmental color distribution, and long transition lengths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

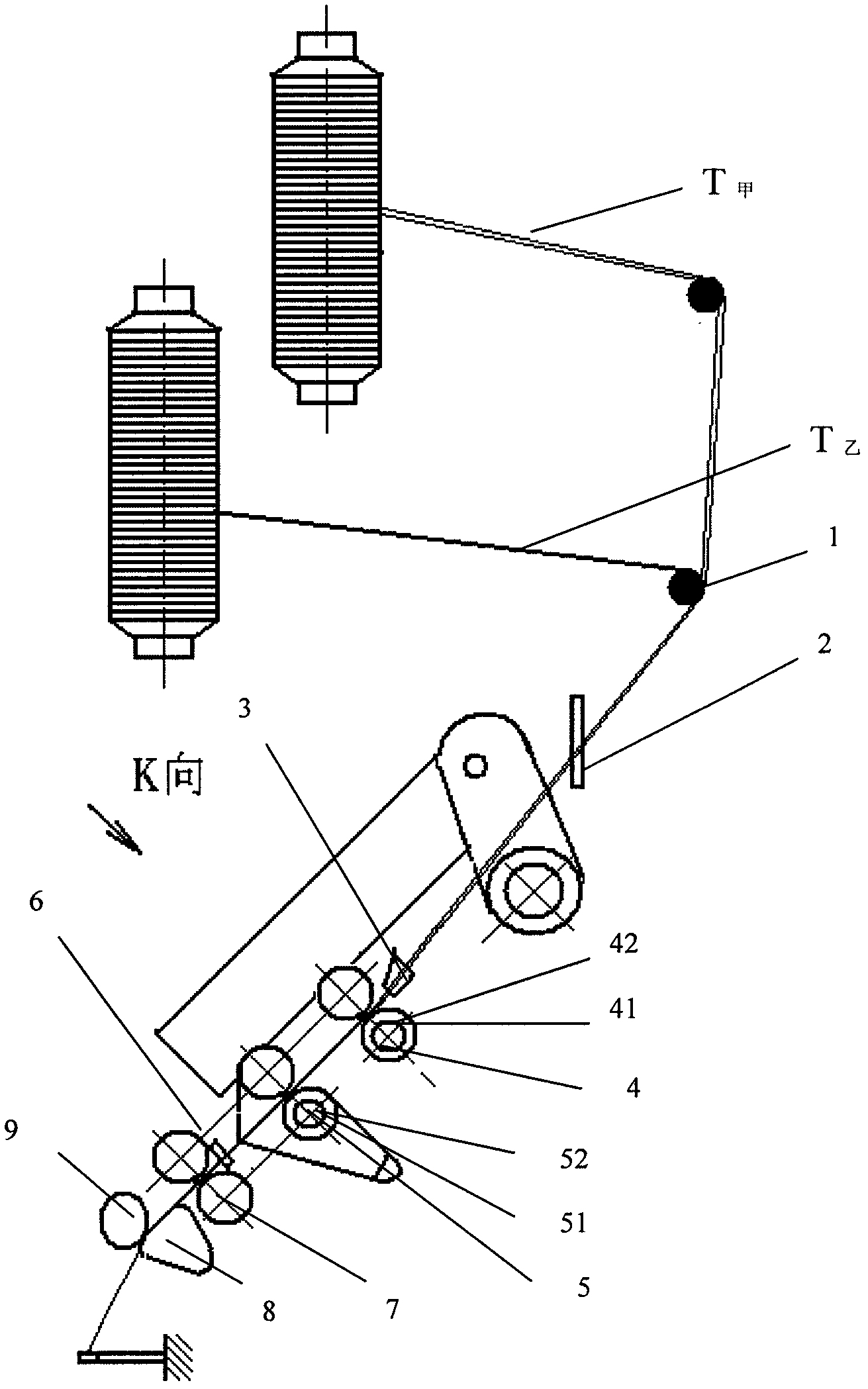

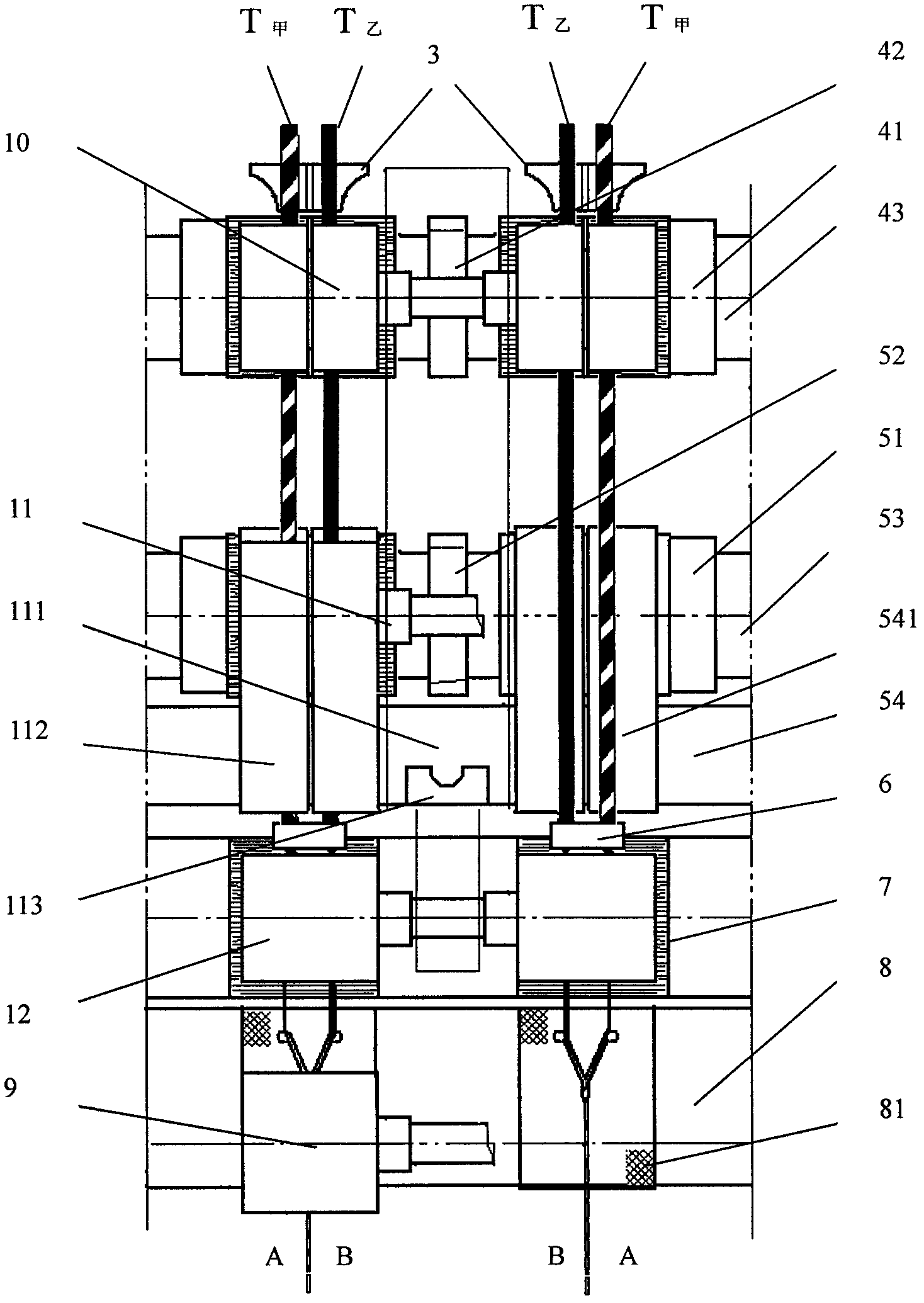

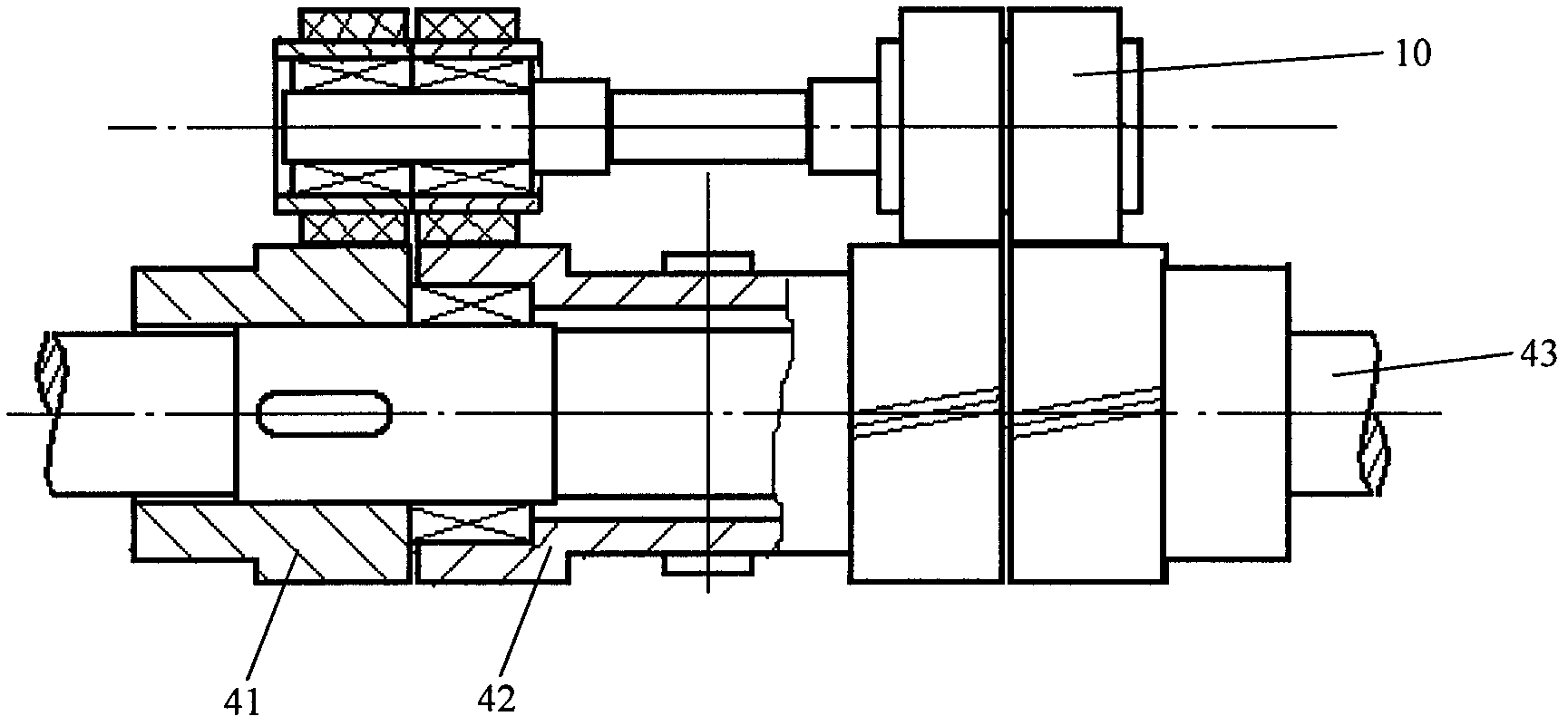

[0027] Such as figure 1 and figure 2 As shown, the method for forming colored yarn by ring spinning section of the present invention, the group A fiber strip T 甲 , the second group of fiber strips T 乙 Feed the back roller 4 through the yarn guide rod 1 and the bell mouth 3 of the split grid 2 respectively, and are respectively clamped by the fixed back roller 41 on the back roller 43 shaft and the looper back roller 42, and then fed into the middle roller shaft 53. The fixed middle roller 51 and the looper middle roller 52 pass through the gauge collector 6 to the front roller 7, and the fiber strands of A and B groups after being drafted and output by the front roller 7 pass through the Y-shaped surface of the negative pressure suction tube 8 Guide grooves, under the action of air guidance, gather together, output through guide rubber roller 9, and are twisted into colored yarns of equal linear density.

[0028] During normal spinning, in the i-th process section, the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com