Levigated coal gasification coarse slag cement base antique material and preparation method and application thereof

A coal gasification and cement-based technology, applied in the field of building materials, can solve the problems of occupying large land resources, transportation costs, waste of resources, pollution of soil and groundwater sources, and achieve the effects of low density, light laying and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

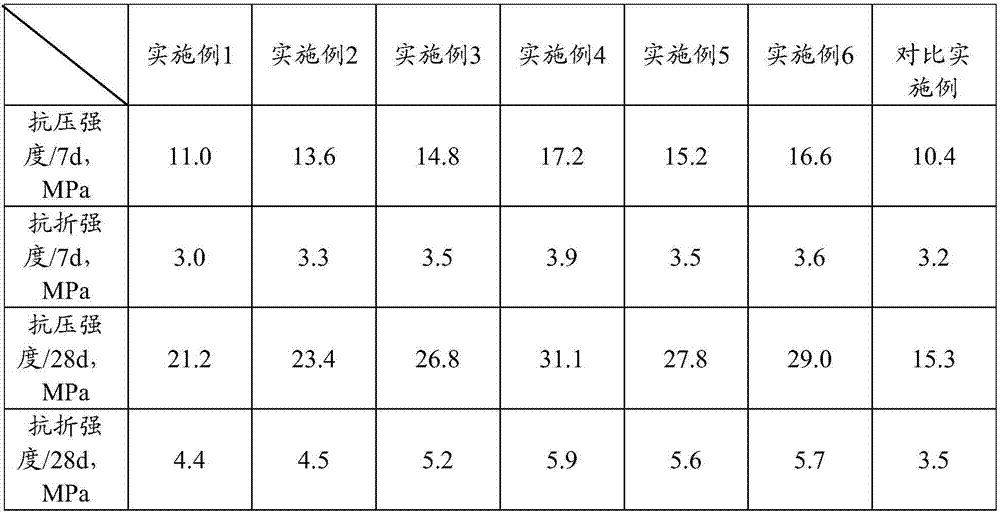

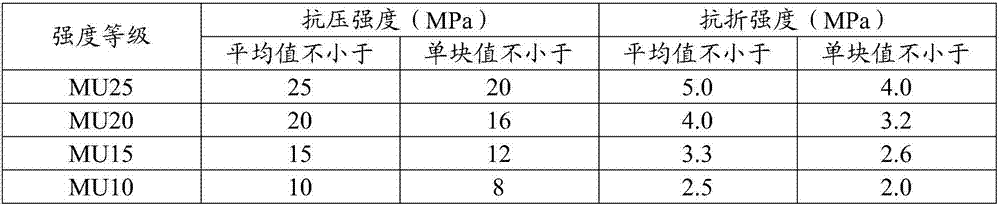

Examples

Embodiment 1

[0030] Raw material formula: 60kg of finely ground coal gasification coarse slag, 3kg of ordinary portland cement, 25kg of medium sand, 8kg of water, 0.02kg of alkali, and 0.05kg of salt.

[0031] Wherein, alkali is the mixture of sodium hydroxide and calcium hydroxide, and the mass ratio of the mass of sodium hydroxide to calcium hydroxide is 1:5; Salt is the mixture of calcium chloride, calcium sulfate and aluminum sulfate, calcium chloride, sulfuric acid The mass ratio of calcium and aluminum sulfate is 1:1:1; the average particle size of finely ground coal gasification coarse slag is 30 μm, and the specific surface area is 260m 2 / kg; Ordinary Portland cement, the strength grade is 42.5, and the specific surface area is not less than 330m 2 / kg; medium sand, the fineness modulus is 3.0-2.3, and the average particle size is 0.5-0.35mm.

[0032] Preparation method: dry the coal gasification coarse slag naturally at room temperature, with a moisture content of 2 / kg, to obta...

Embodiment 2

[0034] Raw material formula: 65kg of finely ground coal gasification coarse slag, 5kg of ordinary portland cement, 20kg of medium sand, 9kg of water, 0.02kg of alkali, and 0.05kg of salt.

[0035] Wherein, alkali is the mixture of sodium hydroxide and calcium hydroxide, and the mass ratio of sodium hydroxide and calcium hydroxide is 1:4; Salt is the mixture of calcium chloride, calcium sulfate and aluminum sulfate, and calcium chloride, calcium sulfate and The mass ratio of aluminum sulfate is 1:0.8:1.5; the average particle size of finely ground coal gasification coarse slag is 35μm, and the specific surface area is 255m 2 / kg; Ordinary Portland cement, the strength grade is 42.5, and the specific surface area is not less than 330m 2 / kg; medium sand, the fineness modulus is 3.0-2.3, and the average particle size is 0.5-0.35mm.

[0036] Preparation method: dry the coal gasification coarse slag naturally at room temperature, with a moisture content of 2 / kg, to obtain coarse c...

Embodiment 3

[0038] Raw material formula: 65kg of finely ground coal gasification coarse slag, 6kg of ordinary Portland cement cement, 15kg of medium sand, 9kg of water, 0.04kg of alkali, and 0.10kg of salt.

[0039] Wherein, alkali is the mixture of sodium hydroxide and calcium hydroxide, and the mass ratio of sodium hydroxide and calcium hydroxide is 1:4.5; Salt is the mixture of calcium chloride, calcium sulfate and aluminum sulfate, calcium chloride, calcium sulfate and The mass ratio of aluminum sulfate is 1:0.8:1.5; the average particle size of finely ground coal gasification coarse slag is 40μm, and the specific surface area is 250m 2 / kg; Ordinary Portland cement, the strength grade is 42.5, and the specific surface area is not less than 330m 2 / kg; medium sand, the fineness modulus is 3.0-2.3, and the average particle size is 0.5-0.35mm.

[0040] Preparation method: Dry the coal gasification coarse slag naturally at room temperature, with a moisture content of 2 / kg, to obtain co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com