Composite rope structures and systems and methods for making composite rope structures

a technology of composite rope and rope structure, applied in the field of composite rope structure and system and method for making composite rope structure, can solve problems such as affecting the characteristics of a rope structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

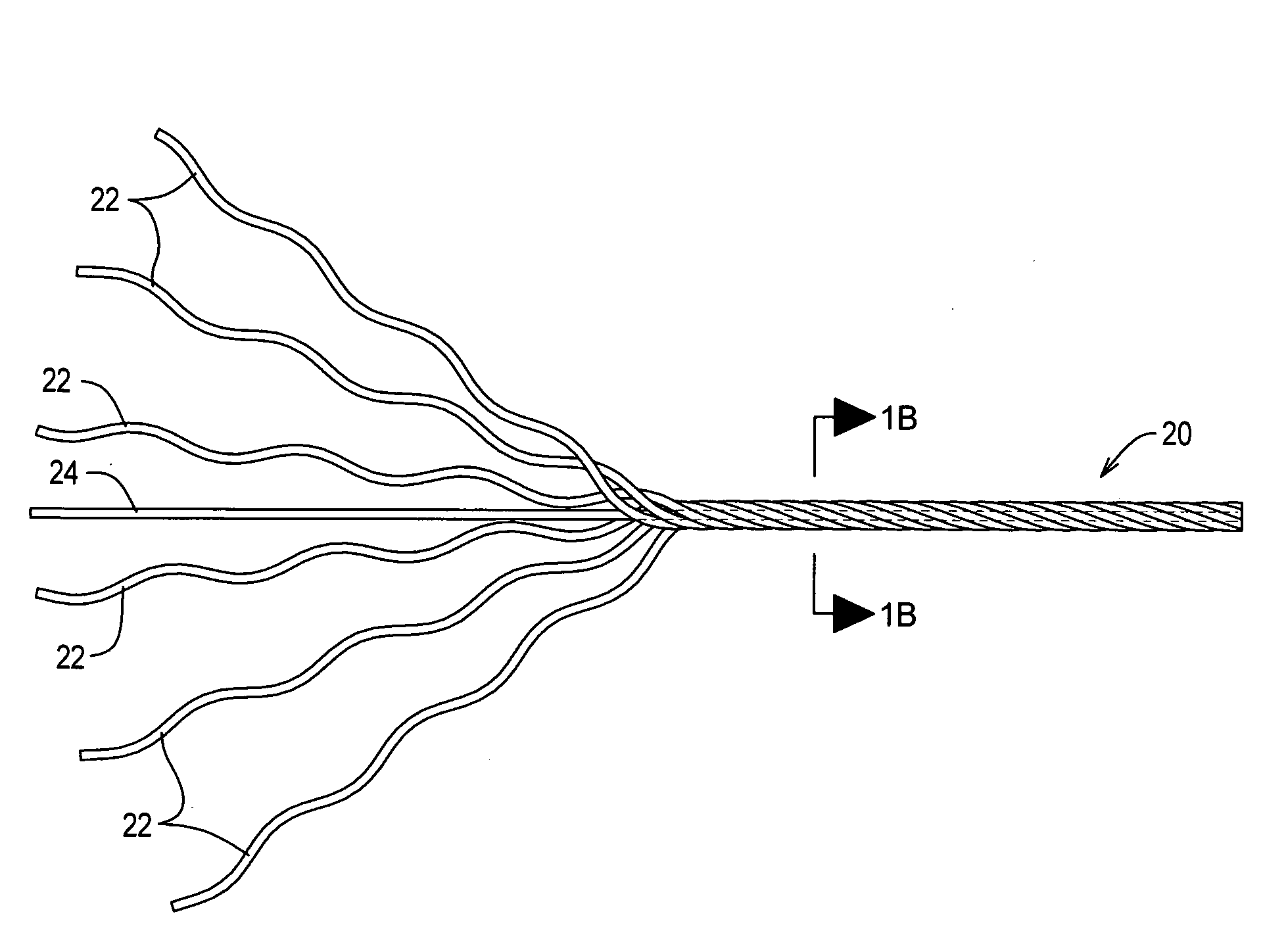

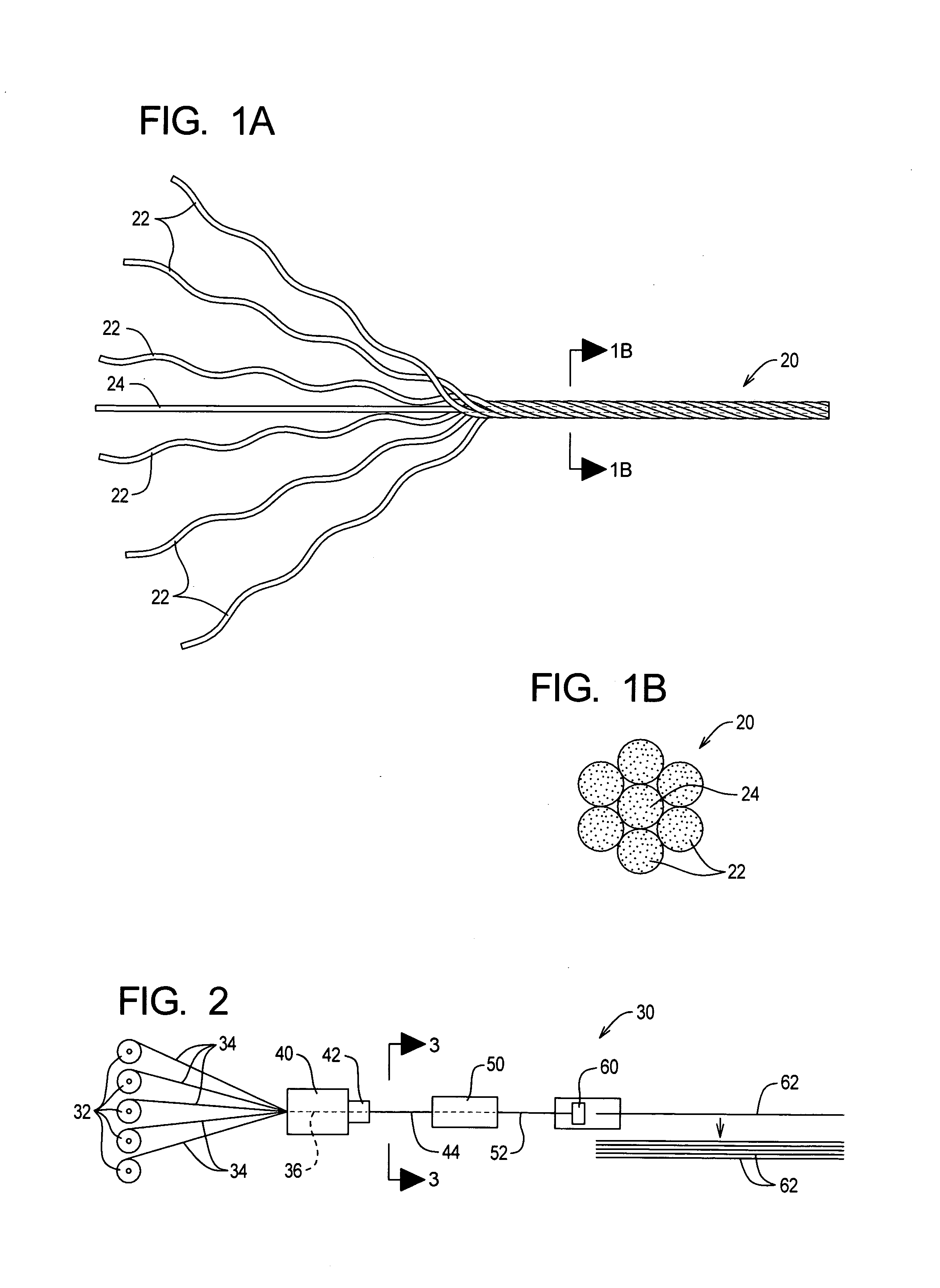

[0026]Referring initially to FIGS. 1A and 1B of the drawing, depicted therein is a composite rope structure 20 constructed in accordance with, and embodying, the principles of the present invention. The composite rope structure 20 comprises a plurality of formed composite strands 22 and a core strand 24. As perhaps best shown in FIG. 7, the formed composite strands 22 are preformed in a substantially helical configuration such that a plurality (two or more) of these formed composite strands 22 are combined with the core strand 24 to form the composite rope structure 20. The example composite rope structure 20 comprises six composite strands 22 surrounding a single core strand 24.

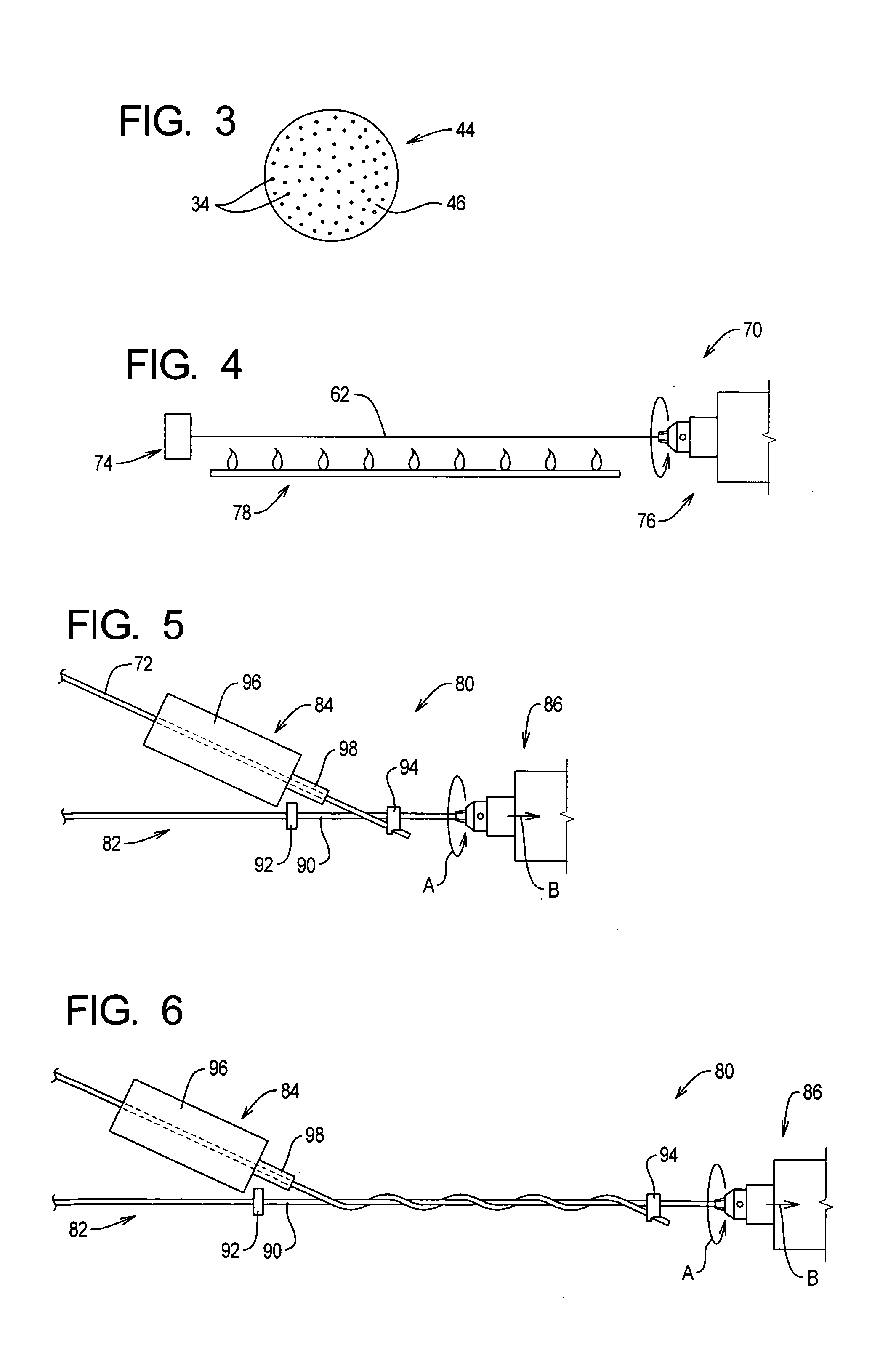

[0027]The composition and fabrication of the example formed composite strands 22 will now be described in further detail. Depicted in FIG. 2 of the drawing is an example blank forming system 30. The blank forming system 30 comprises a plurality of feed rollers 32, with each feed roller 32 containing a length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com