Method and apparatus for manufacturing slalom false twisting on ring yarn

A technology of yarn and false twisting, which is applied in the spinning field of manufacturing single-ply ring-spun yarn, and can solve the problems that the yarn splicing and doffing process cannot fully meet the actual needs of mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

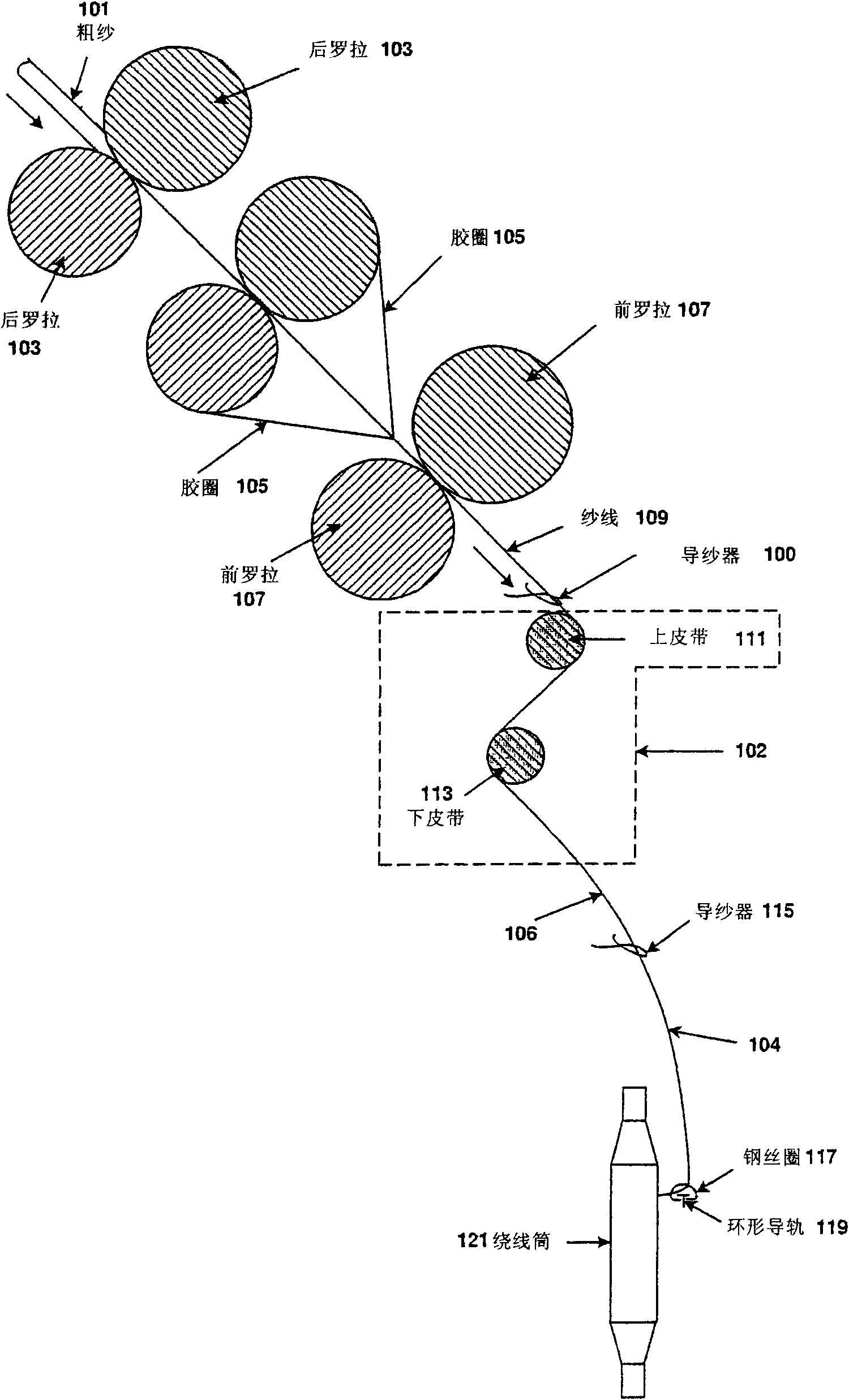

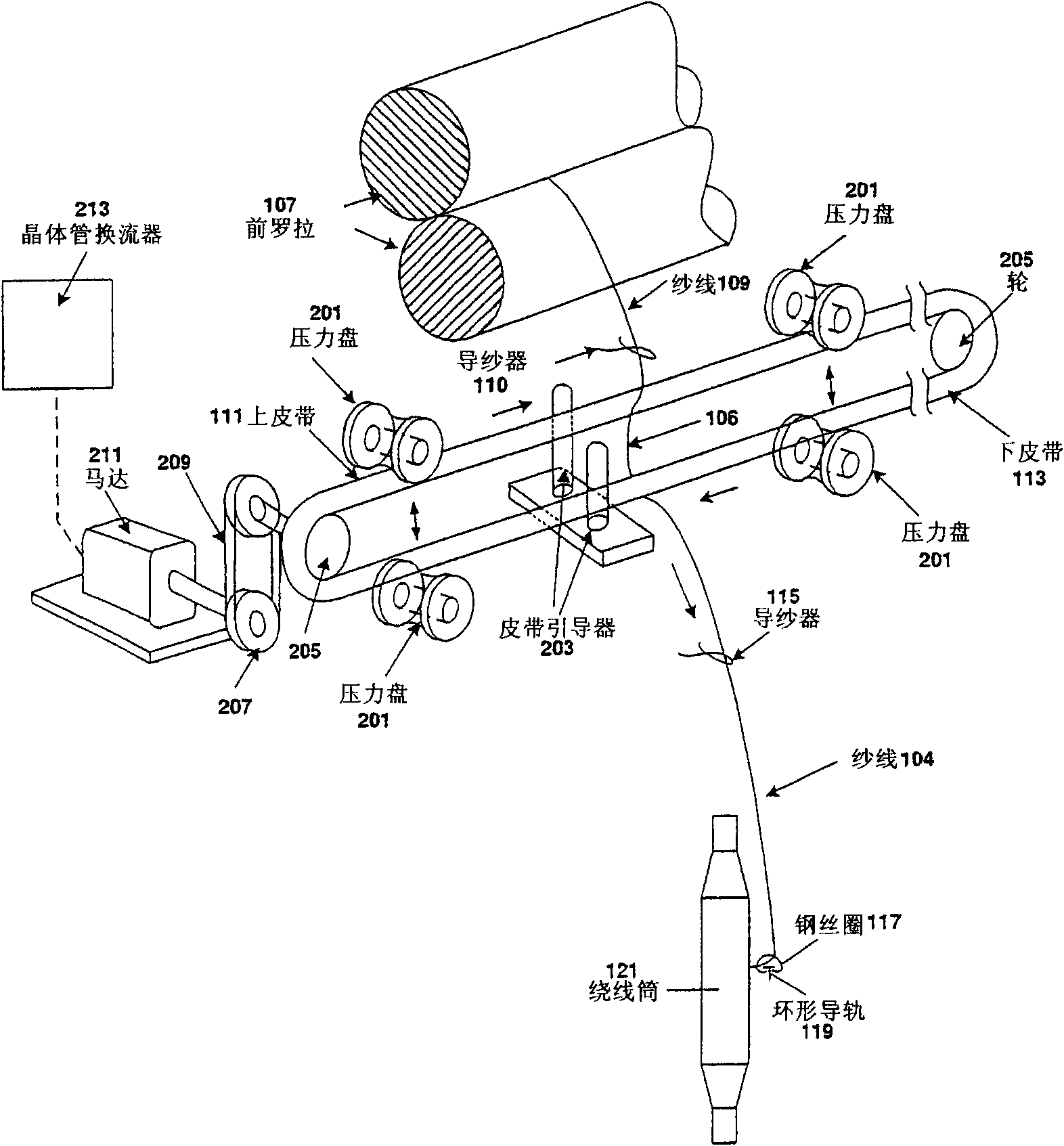

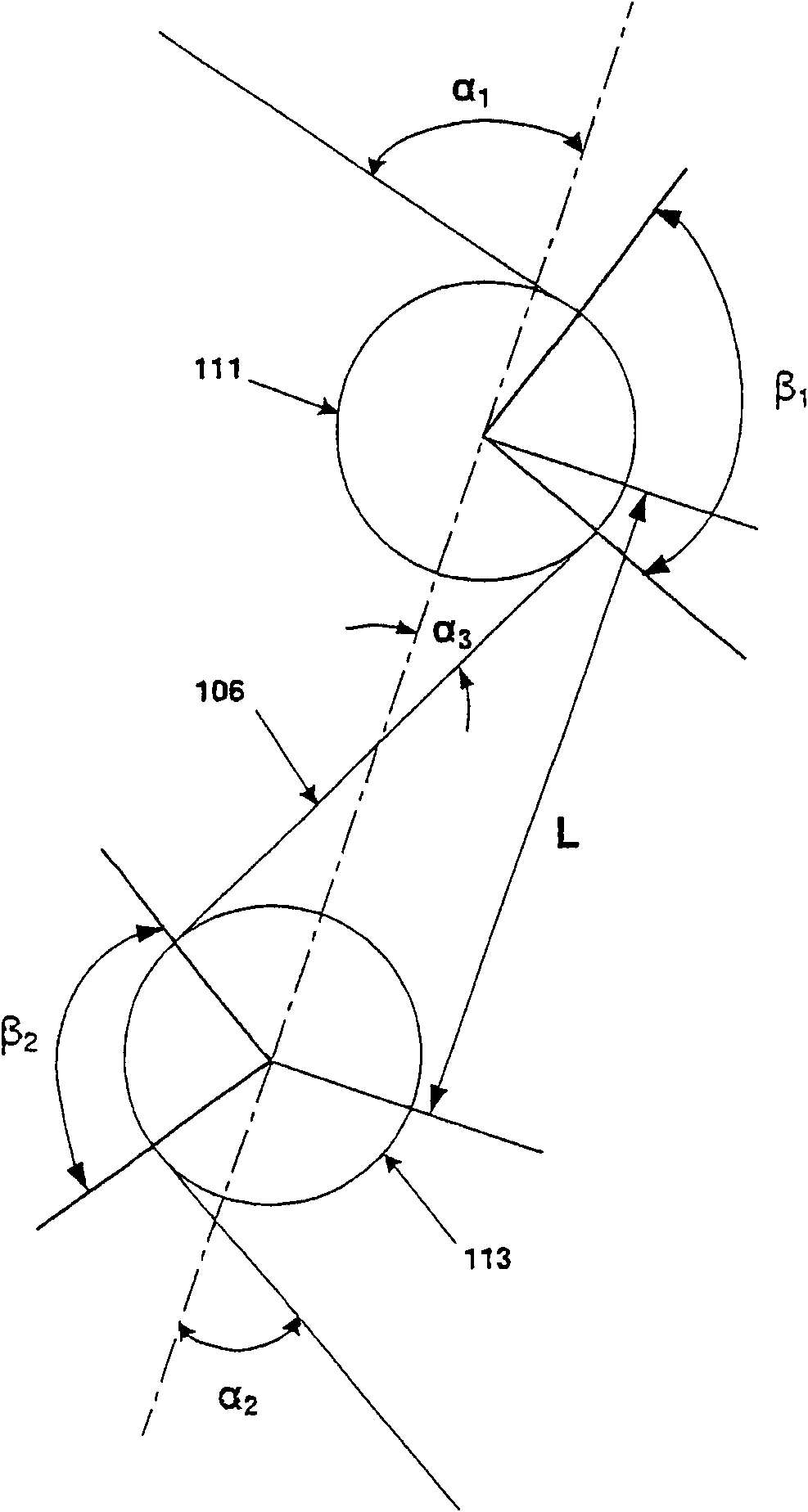

[0032] figure 1 and figure 2 A side plan view and a schematic perspective view of a spinning device according to an exemplary embodiment of the present invention are shown, respectively. Such as figure 1 and figure 2 As shown, a roving 101 is conveyed via a drafting system 103, 105 and 107 comprising a pair of back drafting rollers 103, a pair of aprons 105 and a pair of front drafting rollers (front drafting roller)107. The upper belt 111 of the false twisting device 102 twists the drawn roving to form an initial single-ply yarn, wherein the operation of the upper belt 111 provides false twist to the yarn. Immediately after the false twisting step by means of the upper belt 111 serving as the first twisting point, the combined twist of the second twist in the same direction as the first twist and the third twist in the opposite direction is applied to the initial single-ply yarn 106, For the production of the final single-ply ring yarn, wherein the running of the yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com