Intelligent spinning device and system of rotor spinning machine

A technology of rotor spinning machine and intelligent spinning, which is applied to spinning machines, free-end spinning machines, and continuous winding spinning machines, etc. Low energy consumption and other issues, to achieve the effects of taking into account the effect of waste removal and energy saving, good yarn quality consistency, and wide adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

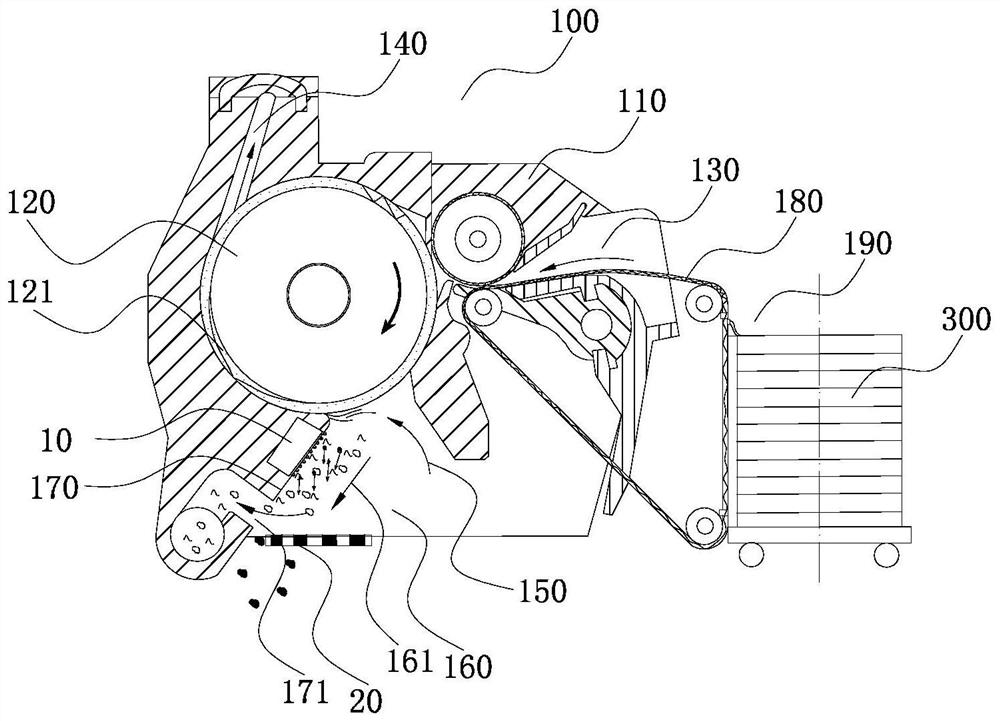

[0062] see figure 1 As shown, it is an intelligent spinning device 100 of a rotor spinning machine provided by the present invention, which includes a sliver feeding mechanism and an impurity discharging and carding mechanism.

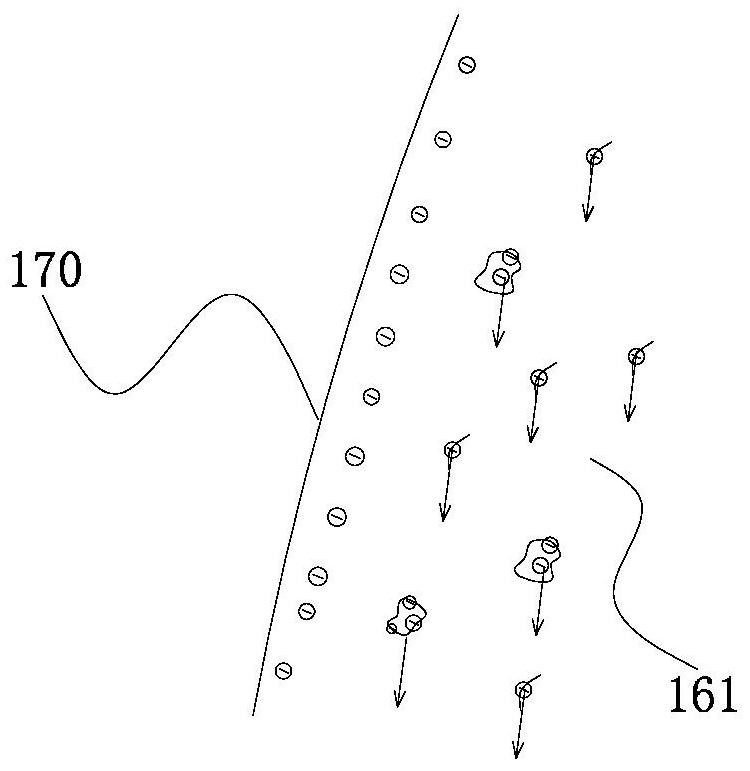

[0063] The impurity removal and carding mechanism includes a casing 110 provided with an opening chamber, an opening roller 120 is installed in the opening chamber, and a sliver feeding mechanism 130 which is respectively communicated with the opening chamber is arranged on the casing 110. and Fibre Channel 140.

[0064] The left side of the opening roller 120 is provided with a fiber transfer area 121 for transferring the carded sliver. The fiber transfer area 121 is arranged below the fiber feeding channel 140 , and the sliver first passes through the fiber transferring area 121 after being carded, and then is transported to the rotor through the fiber feeding channel 140 .

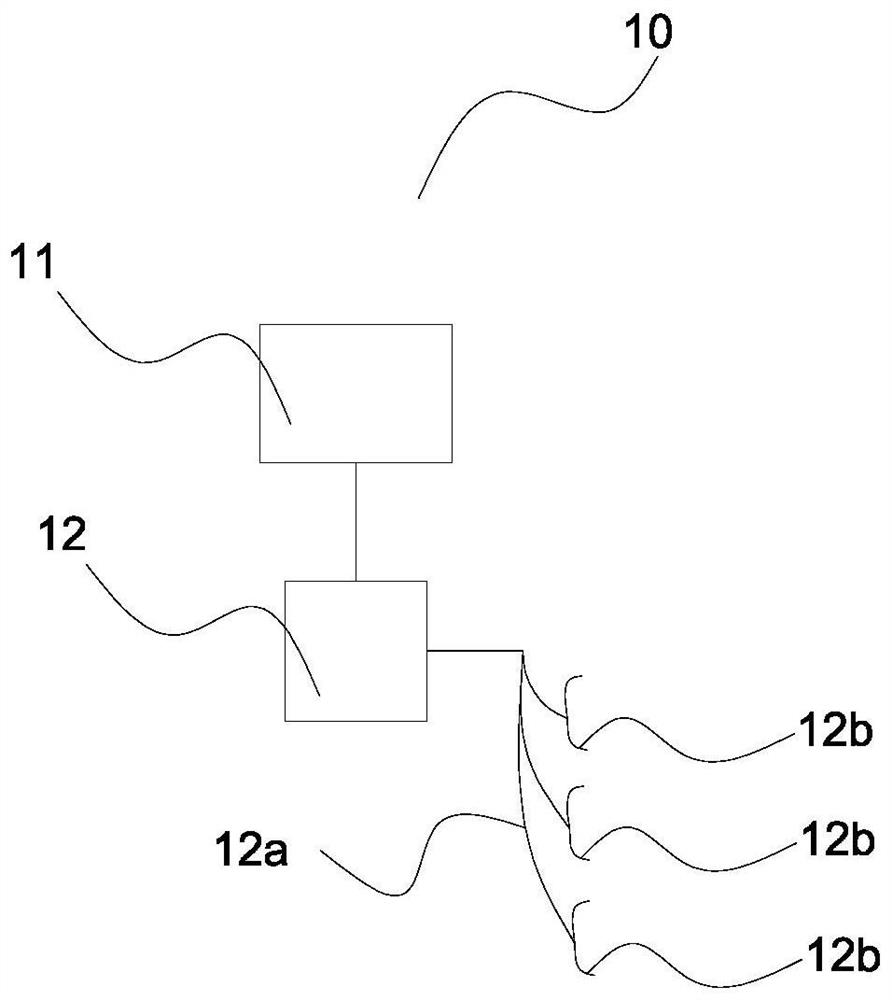

[0065] The sliver feeding mechanism 130 includes a sliver guide and a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com