Biomass poly-generation equipment and method of integral pyrolysis-flue gas combined cycle

A combined cycle and biomass technology, applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of large amount of flue gas generation, poor controllability, and insufficient integration, and achieves the reduction of internal friction and adaptability. The effect of wide range and reduction of total demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

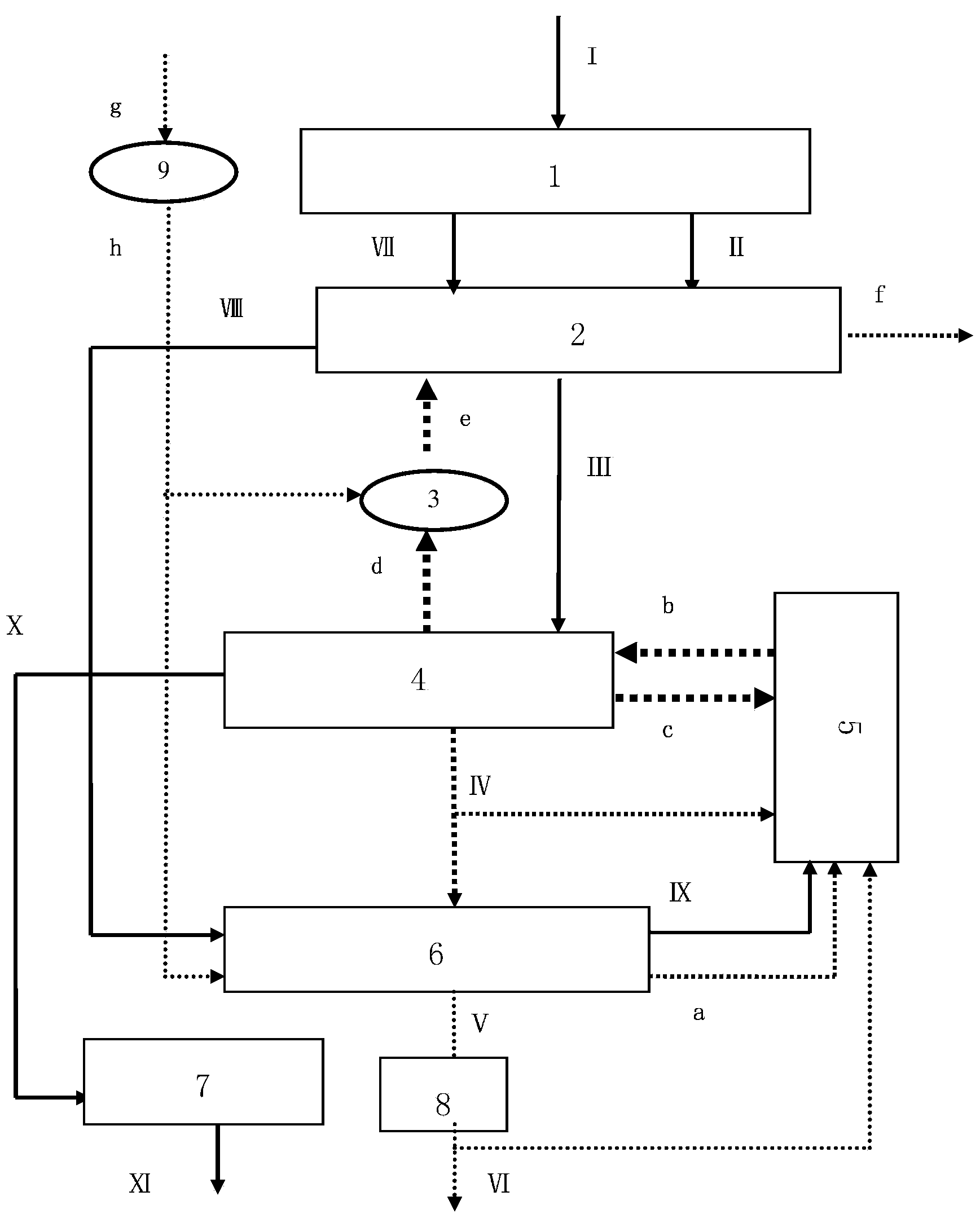

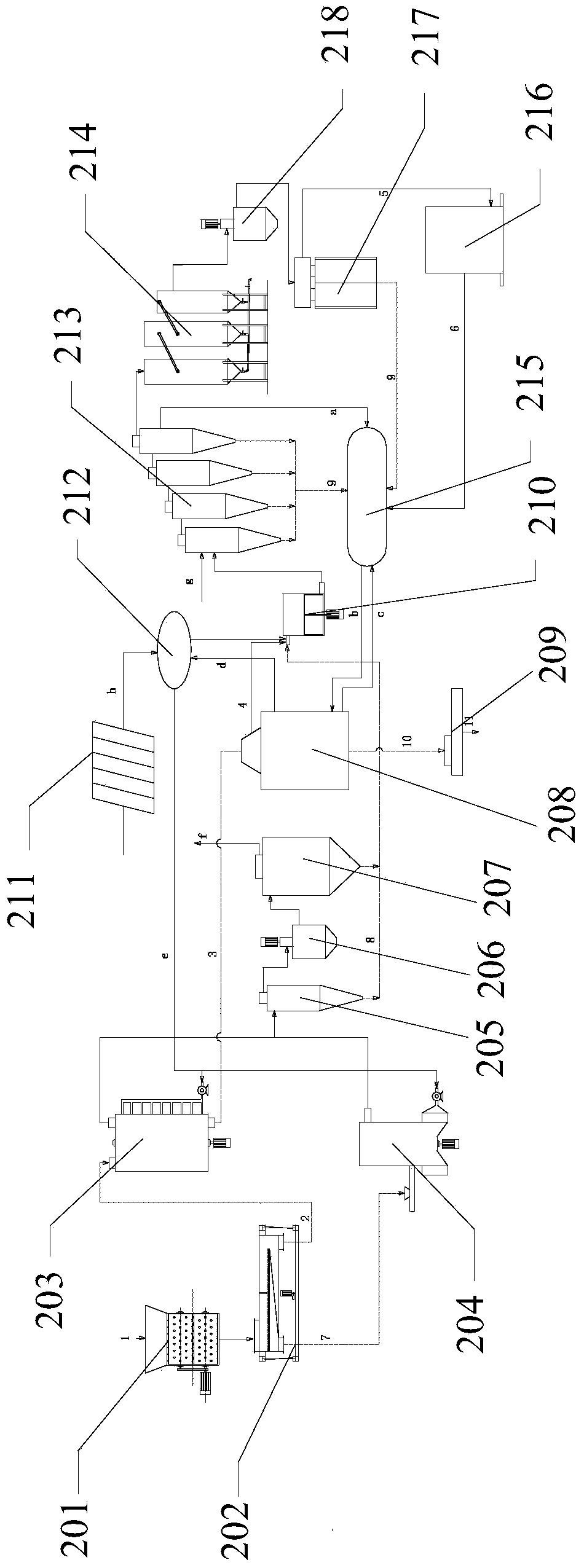

[0042] figure 1 It is the composition relationship and flowchart of the equipment and method of the present invention. The equipment of the present invention includes a pretreatment system 1, a drying system 2, a temperature adjustment system 3, an integral pyrolysis furnace 4, a comprehensive combustion furnace 5, a gas purification system 6, and a carbon forming system. 7. Gas storage cabinet 8. Solar collector 9. The pretreatment system 1 processes the biomass raw material I through crushing, screening, and impurity removal in sequence into granular material II (particle size 0.2-5cm) and powder material VII (particle size ≤ 2mm), and passes through the screw conveyor respectively. Send to drying system 2. Drying system 2 mixes granular material II and powder material VII (from pretreatment system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com