Rotational-flow electrolysis method and device thereof

A swirl electrolysis and swirl cell technology, which is applied in photography technology, instruments, photography auxiliary technology, etc., can solve the problems of uneven current distribution, difficulty in removing impurities from solution, and low electrolysis current density, so as to avoid acid mist emission. , The effect of reducing technical risk and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

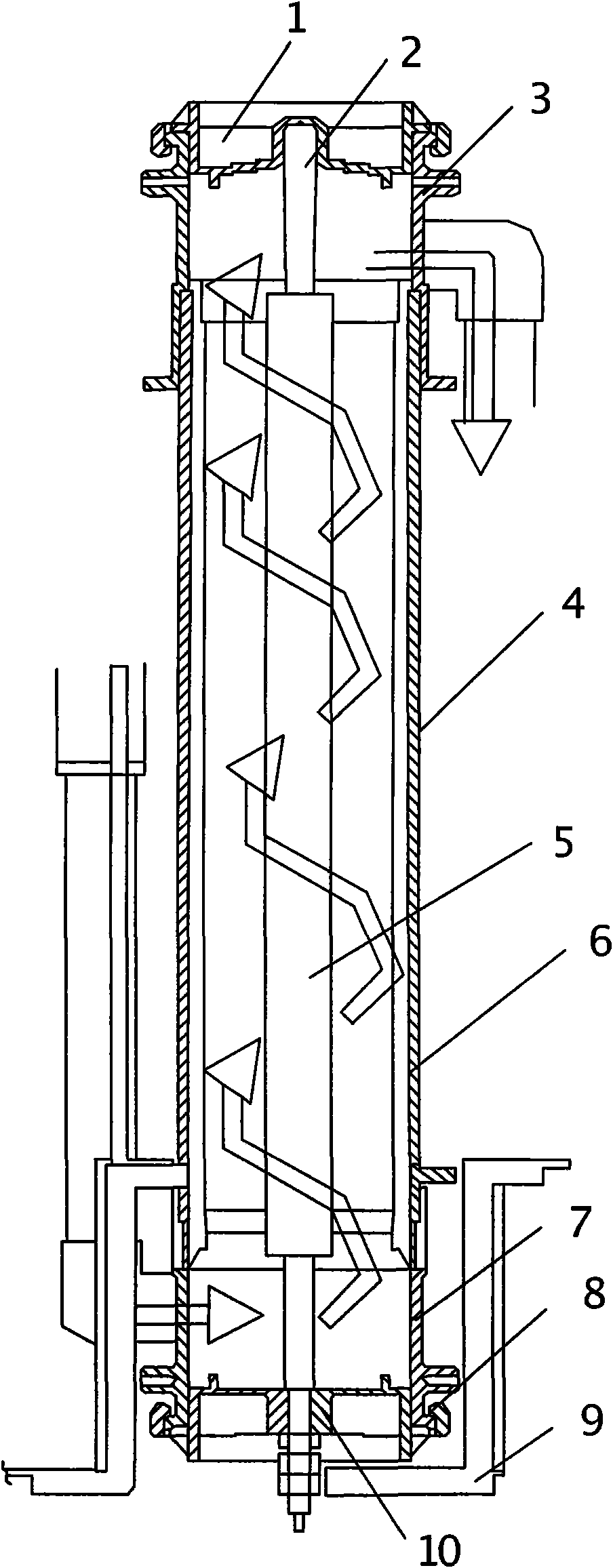

[0035] Next, a cyclone electrolysis method and its device of the present invention will be described in detail below with reference to the accompanying drawings.

[0036] In the swirling flow electrolysis method of the present invention, the solution in the swirling flow tank container rotates and flows in a spiral shape during the electrolysis process. It can perform selective electrolysis (electrowinning) on valuable metals, and is especially suitable for the selective electrolysis (electrowinning) separation and purification of low-concentration and complex-component solutions in the metallurgical industry, as well as the stripping of heavy metal ions in wastewater.

[0037] A device for swirl electrolysis method, its structure includes cathode 6, coating anode 5, upper connector 3, lower connector 7, upper end cover 1, lower end cover 10, electrolysis swirl cell body 4; The coated anode and cathode in the electrolytic whirlpool are respectively located in its center and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com