A kind of ionic liquid type polyoxometalate catalyst and its preparation method and application

A technology of polyoxometalates and ionic liquids, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve problems such as no reports, achieve reduced operating time and temperature, and good product selection Sexuality and the effect of reducing application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh a certain amount of H 6 P 2 Mo 18 o 62 Fully dissolved in distilled water, different molar ratios of 1-(3-sulfonic acid) propyl-3-methylimidazole (MIMPS) were added to H 6 P 2 Mo 18 o 62 solution, the resulting mixture was aged at room temperature for 2-5h, suction filtered, washed, and dried to obtain [MIMPS] with n=1-6 n h 6-n P 2 Mo 18 o 62 Catalyst, and measure its productive rate, productive rate is 50-72%, wherein mechanical loss and man-made loss have bigger influence to productive rate, the results are shown in Table 1.

[0043] Table 1

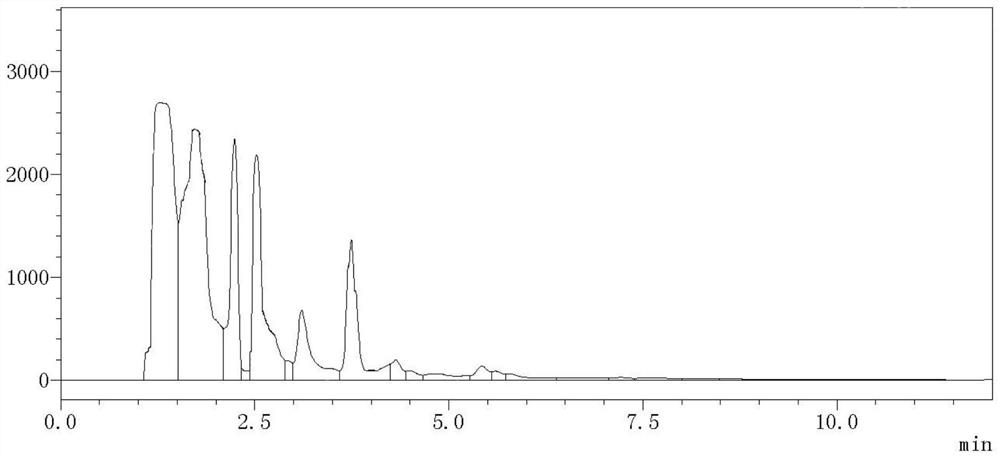

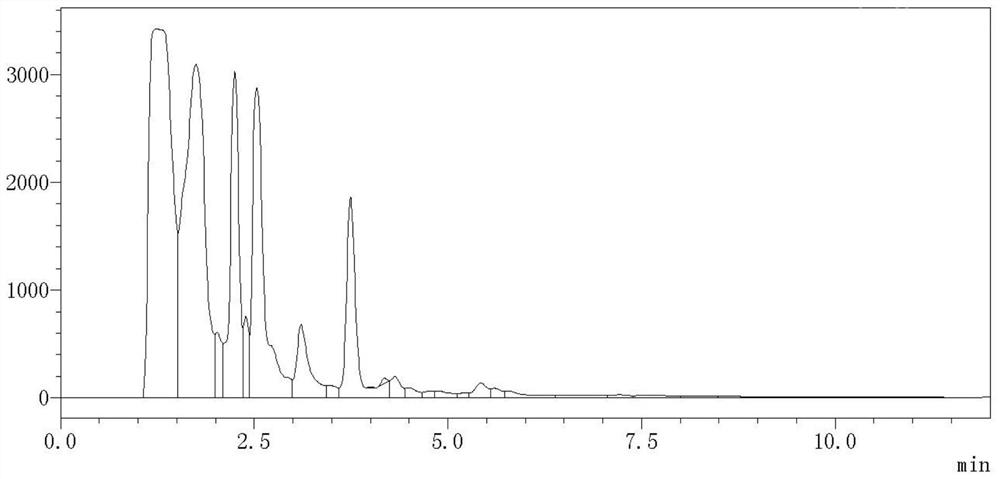

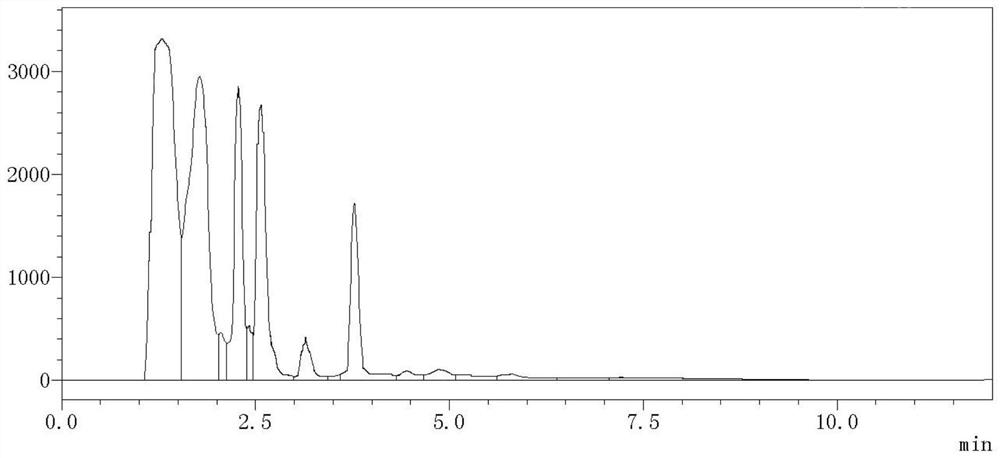

[0044]

[0045]

[0046] The method for catalyzing the multistage stepwise reaction of corn stalks with the ionic liquid type polyoxometalate catalyst provided by the invention is as follows:

[0047] In the autoclave, add 10~50mg of corn stalks and [MIMPS] n h 6-n P 2 Mo 18 o 62 Catalyst, when the mixed liquid is heated to 120-160°C, the pressure is 0.5-1.5MPa of oxygen, and the reaction is carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com