Device for preparing synthetic gas by virtue of non-thermal arc plasma pyrolysis of coal

A coal-to-synthesis gas and plasma technology, which is used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of large equipment investment, short process, high operation and maintenance costs, and achieve wide adaptability of raw materials and investment costs. Low, high hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

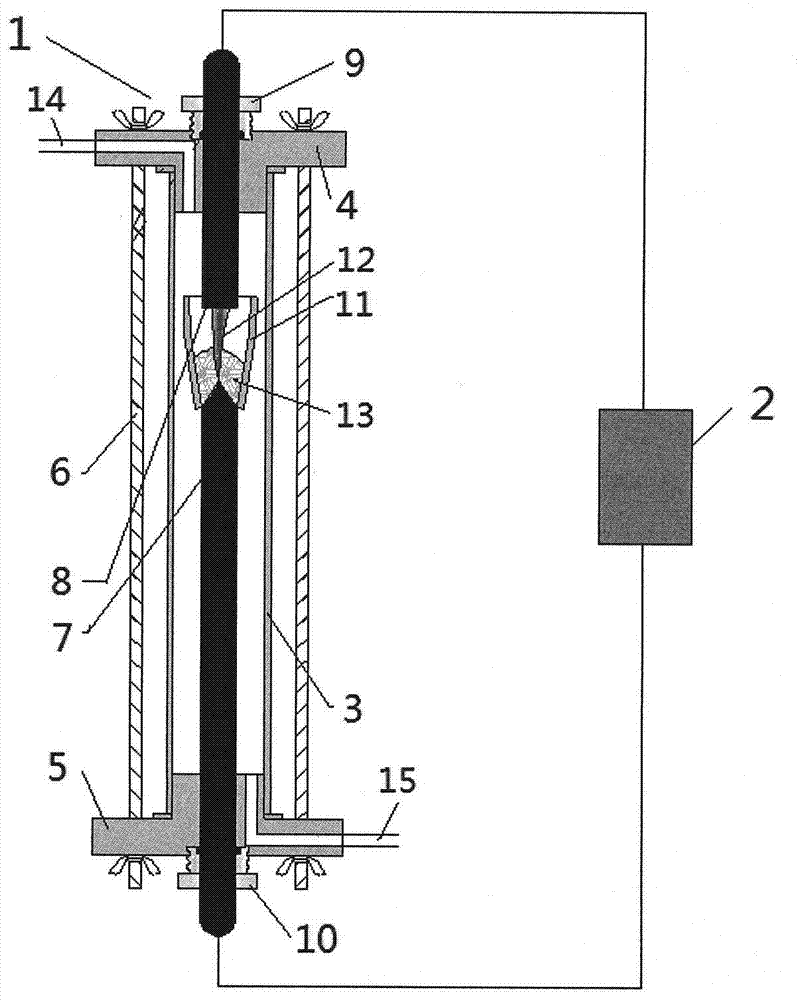

[0011] as attached figure 1 As shown, the present invention includes a non-thermal arc plasma reactor 1 and a high-voltage power supply 2 for powering the plasma reactor; the non-thermal arc plasma reactor includes a quartz container 3, an upper polytetrafluoroethylene flange 4, a lower polytetrafluoroethylene Fluoroethylene flange 5, stainless steel bracket 6, tip graphite electrode 7, flat bottom graphite electrode 8, upper copper sealing ring 9, lower copper sealing ring 10, ceramic crucible 11, non-thermal arc plasma 12, domestic garbage 13, air intake channel 14. Gas outlet channel 15; the tip graphite electrode (φ20mm) and the flat graphite electrode (φ20mm) are connected to the high voltage power supply (10kV / 200mA) through a high-voltage wire, and the tip graphite electrode and the flat graphite electrode are coaxially placed in a quartz container (using quartz glass Tube, length 500mm, inner diameter 40mm), the electrode spacing is fixed at 16mm, the quartz container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com