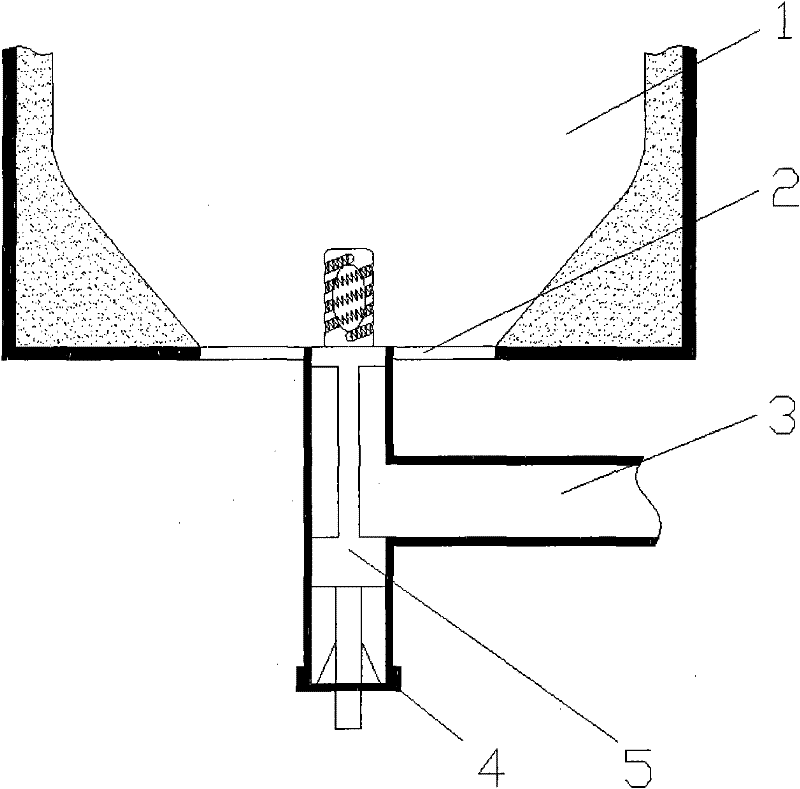

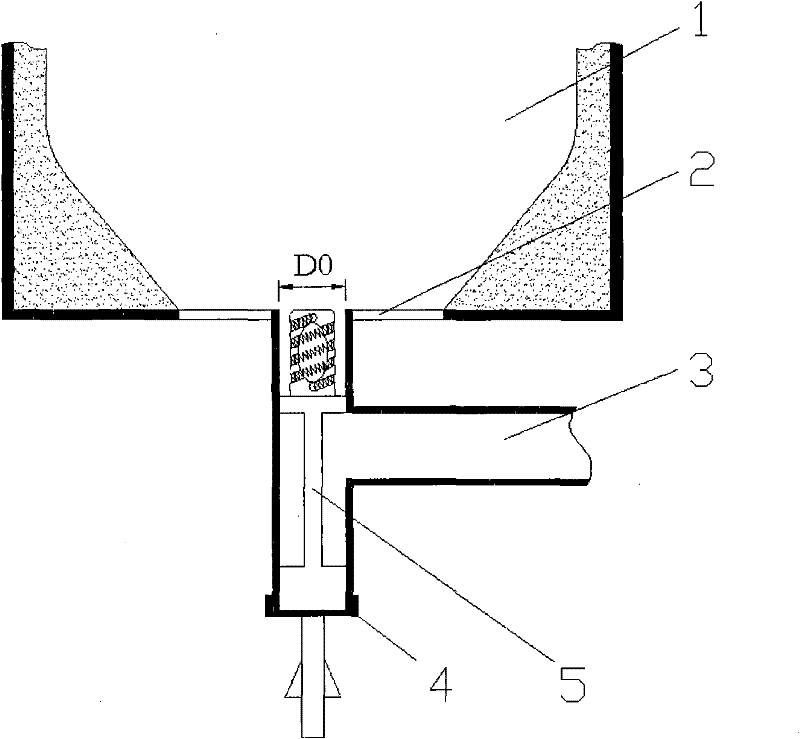

Ignition device for biomass gasification furnace and using method thereof

An ignition device and biomass technology, applied in the directions of combustion ignition, combustion method, incandescent ignition, etc., can solve the problems of easy ignition failure, broken ignition rod, high cost, and achieve wide raw material adaptability, prolong service life, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

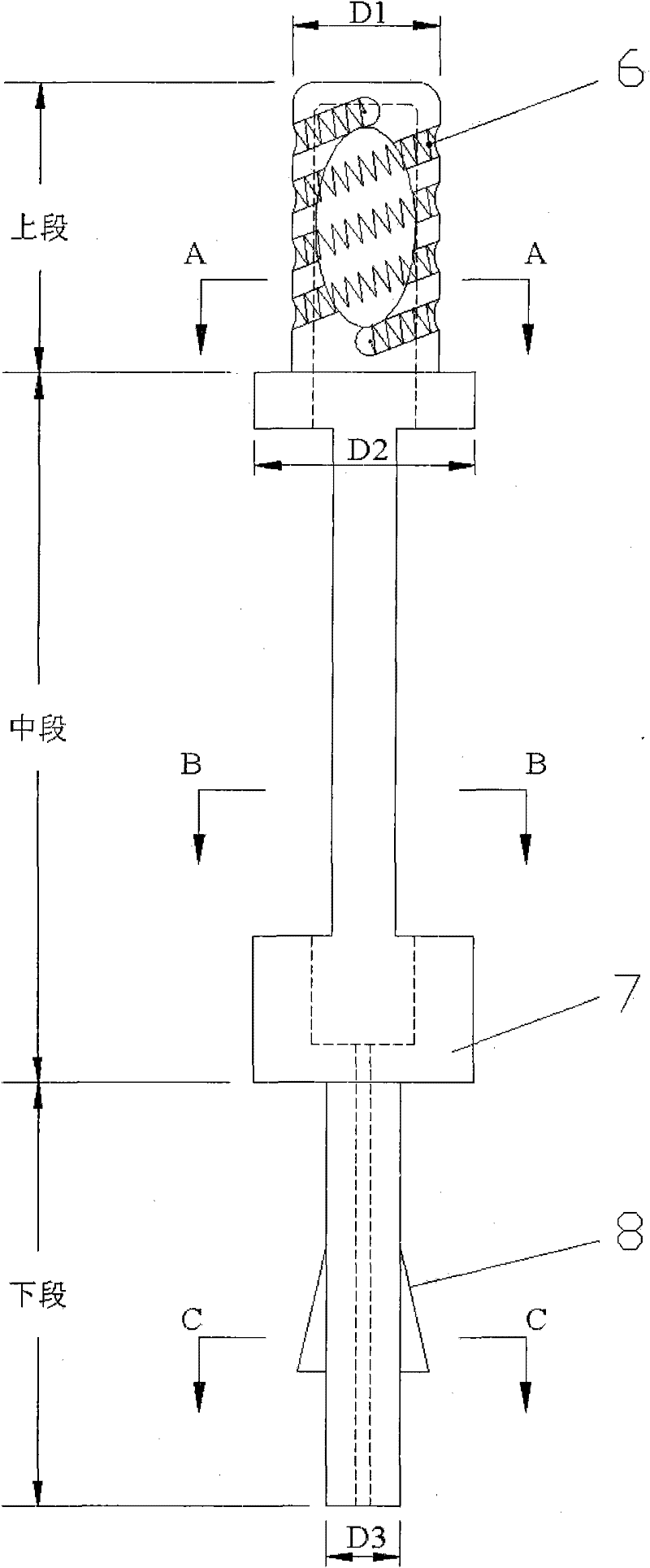

[0034] Straw is used as a raw material, the moisture content of the raw material is 12%, and the length is 5-15mm. Rotate the ignition rod so that its upper end protrudes from the tee-shaped air intake pipe, fill and compact the biomass gasifier, turn on the ignition rod power for 10 seconds, turn on the fan, and turn off the ignition rod power after another 10 seconds, twitch And rotate the ignition rod so that it retracts into the inside of the three-way intake pipe. After 3 minutes, ignitable biomass gasification synthesis gas was obtained.

Embodiment 2

[0036] Rice husk is used as a raw material, the moisture content of the raw material is 10%, and the particle size is 2-4 mm. Rotate the ignition rod so that its upper end protrudes from the tee-shaped air intake pipe, fill and compact the biomass gasifier, turn on the ignition rod power for 10 seconds, turn on the fan, and turn off the ignition rod power after another 10 seconds, twitch And rotate the ignition rod so that it retracts into the inside of the three-way intake pipe. After 2 minutes, ignitable biomass gasification synthesis gas was obtained.

Embodiment 3

[0038] Corn stalks are used as raw materials, the moisture content of the raw materials is 13%, and the length is 5-15 mm. Rotate the ignition rod so that its upper end protrudes from the tee-shaped air intake pipe, fill and compact the biomass gasifier, turn on the ignition rod power for 10 seconds, turn on the fan, and turn off the ignition rod power after another 10 seconds, twitch And rotate the ignition rod so that it retracts into the inside of the three-way intake pipe. After 3 minutes, ignitable biomass gasification synthesis gas was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com