Patents

Literature

44results about How to "Short ignition time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

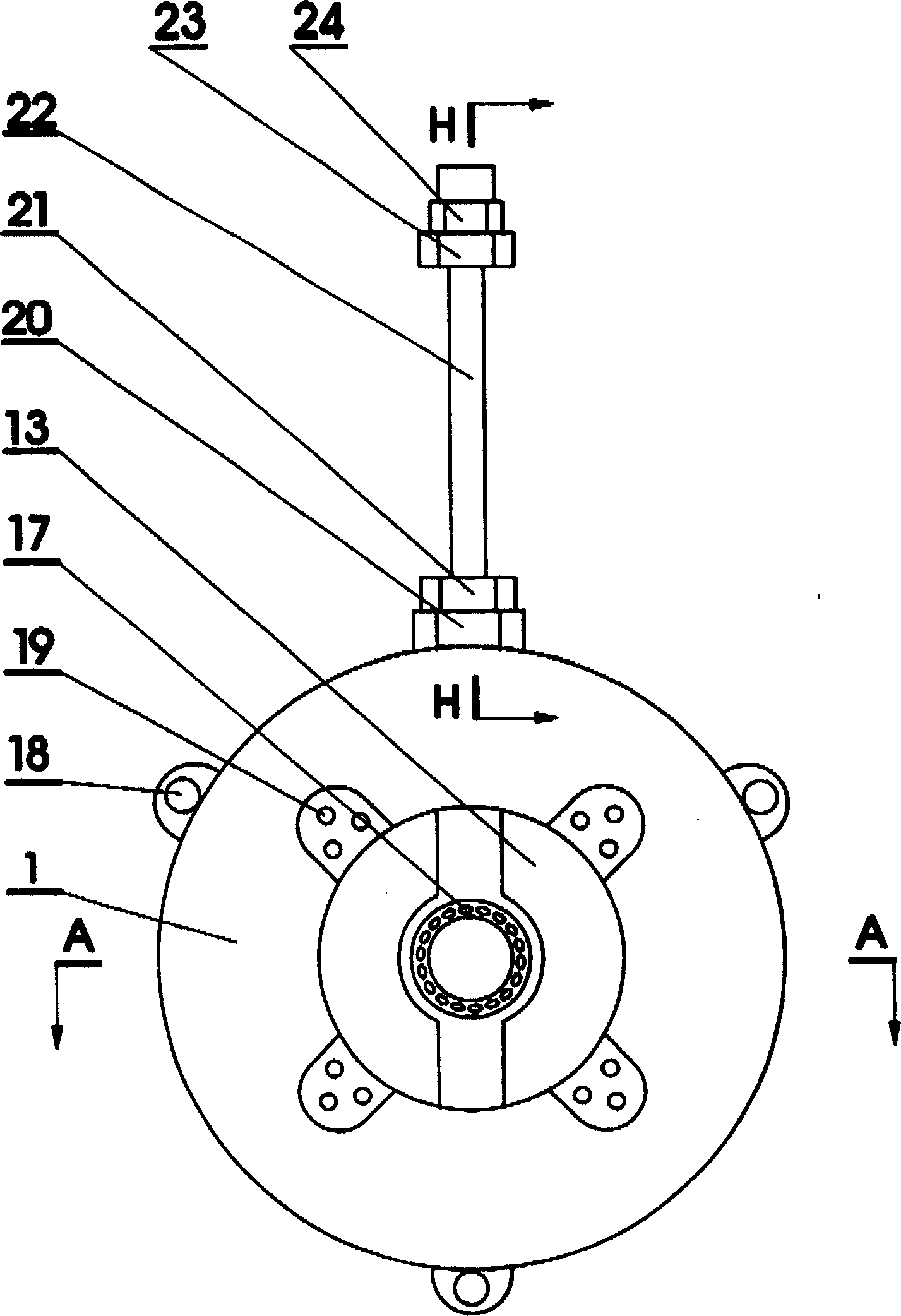

Small-size quickly separated firer-unlocking bolt

InactiveCN102155883ARealize the separation functionShort ignition timeScrewsSelf-propelled projectilesEngineeringMicrosecond

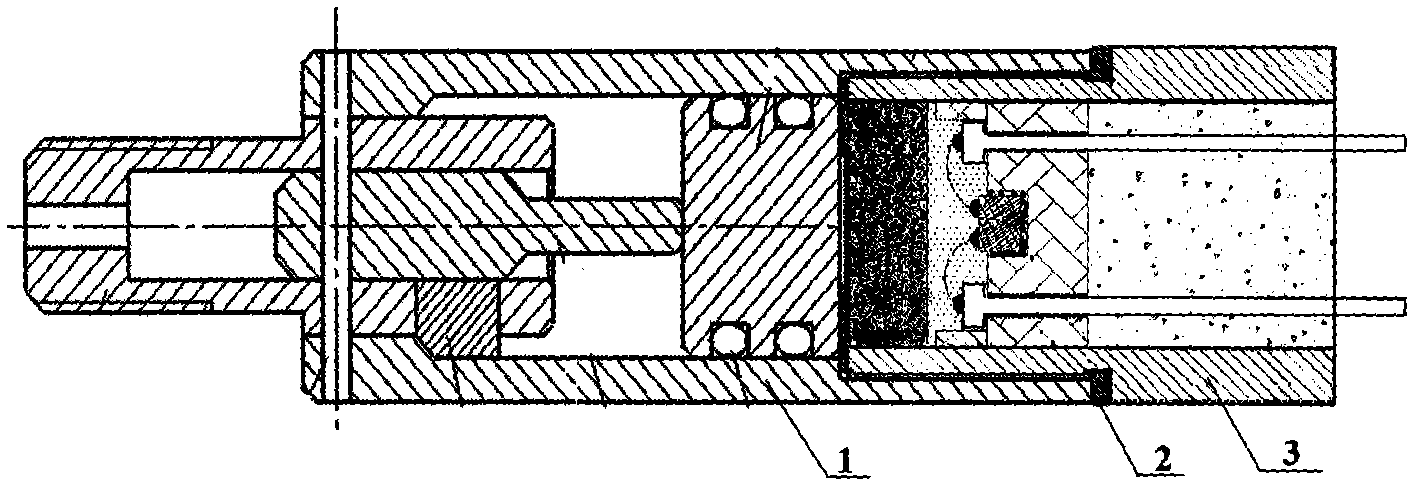

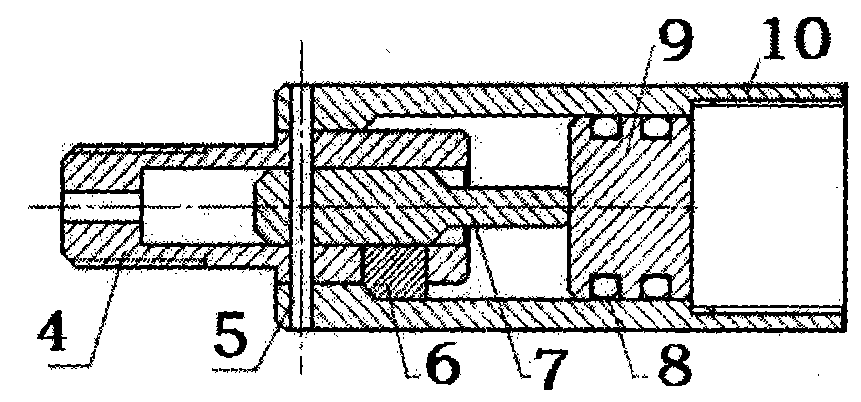

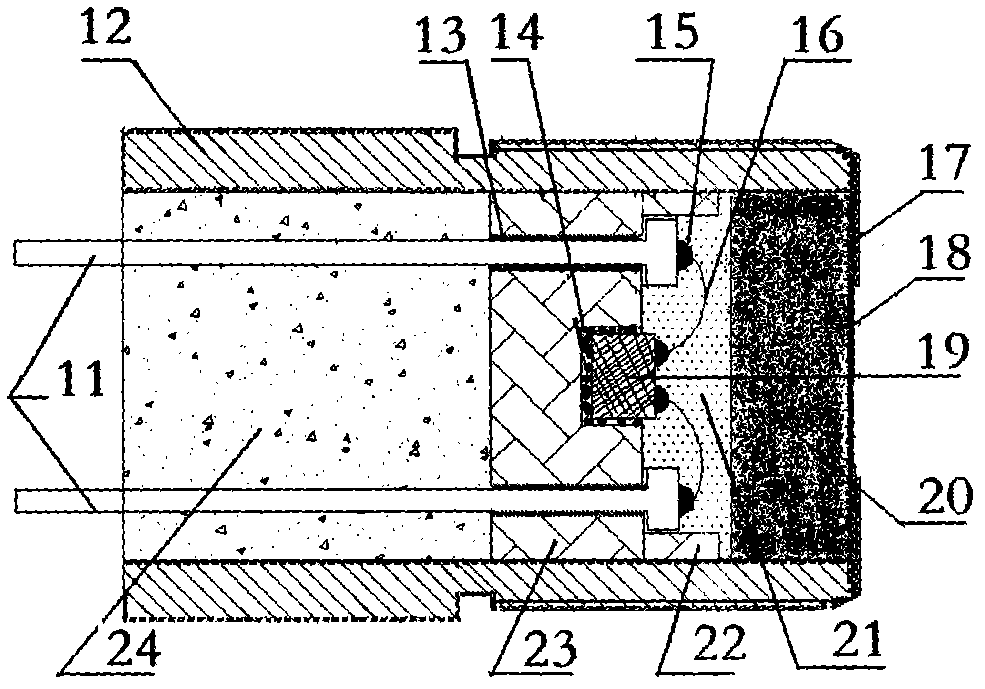

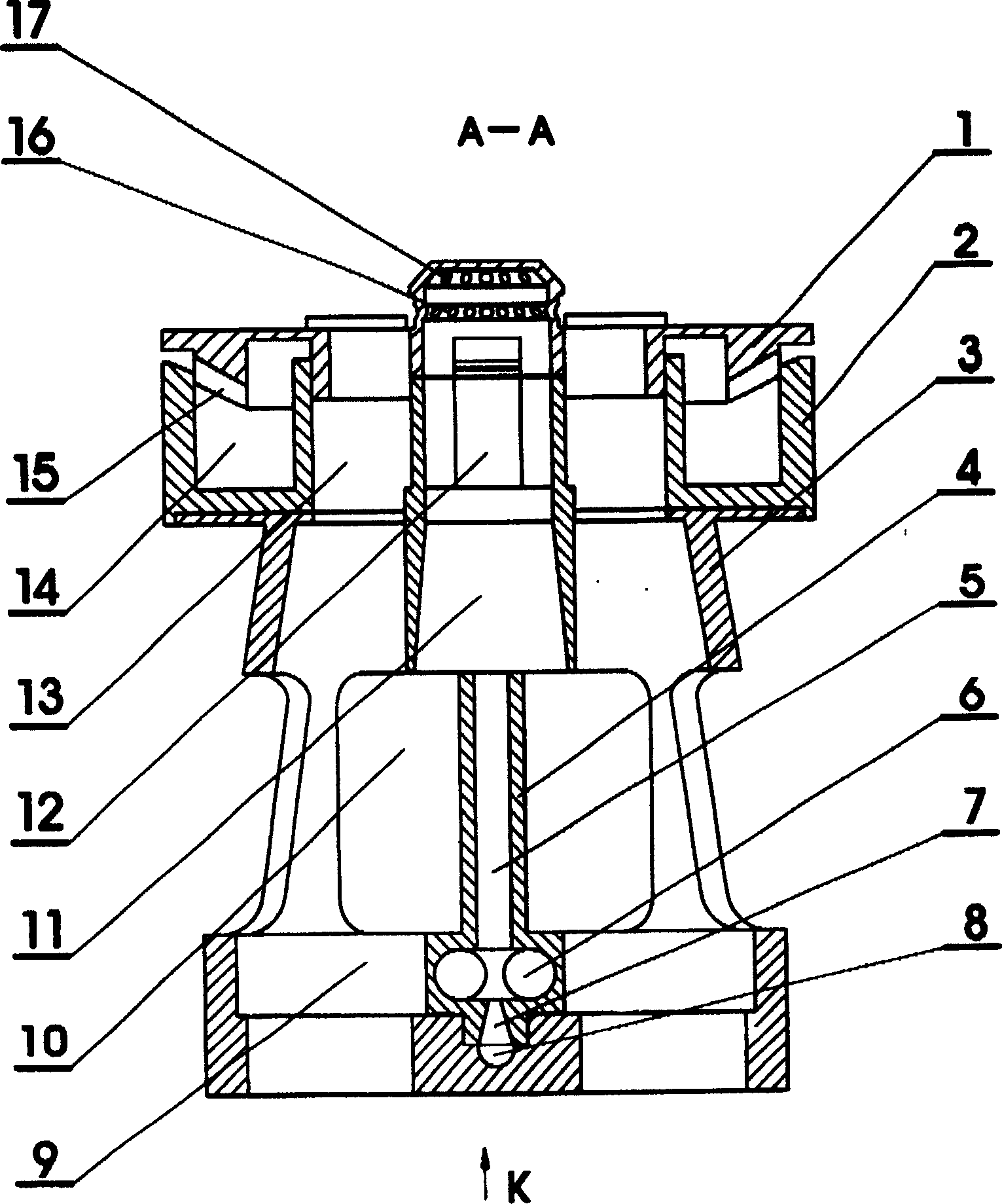

The invention provides a small-size quickly separated firer-unlocking bolt. The small-size quickly separated firer-unlocking bolt comprises an unlocking bolt main body (1), a sealing ring (2) and a semiconductor bridge-type pressure cartridge case (3). In the small-size quickly separated firer-unlocking bolt, a semiconductor bridge firing element is adopted as a firer connection and separation mechanism of the firing element; the whole axial length of the small-size quickly separated firer-unlocking bolt is 60 to 65 millimeters, and the radial size is less than or equal to 16 millimeters; the separation time of the small-size quickly separated firer-unlocking bolt is 1.0 to 1.1 microseconds, the separation synchronism is 0.10 to 0.15 microseconds, and the connection bearing capacity is 21 to 25kN. The small-size quickly separated firer-unlocking bolt has the characteristics of small structural size, short separation time, high synchronism, low firing energy and the like; a safe, quick and synchronous separation function of the interstage of a spacecraft can be realized; the small-size quickly separated firer-unlocking bolt can be directly applied to interstage separation systems of the spacecrafts such as high-speed guided missiles, airships, satellites and the like; meanwhile, a beneficial reference is provided for a design of a similar power source firer mechanism.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

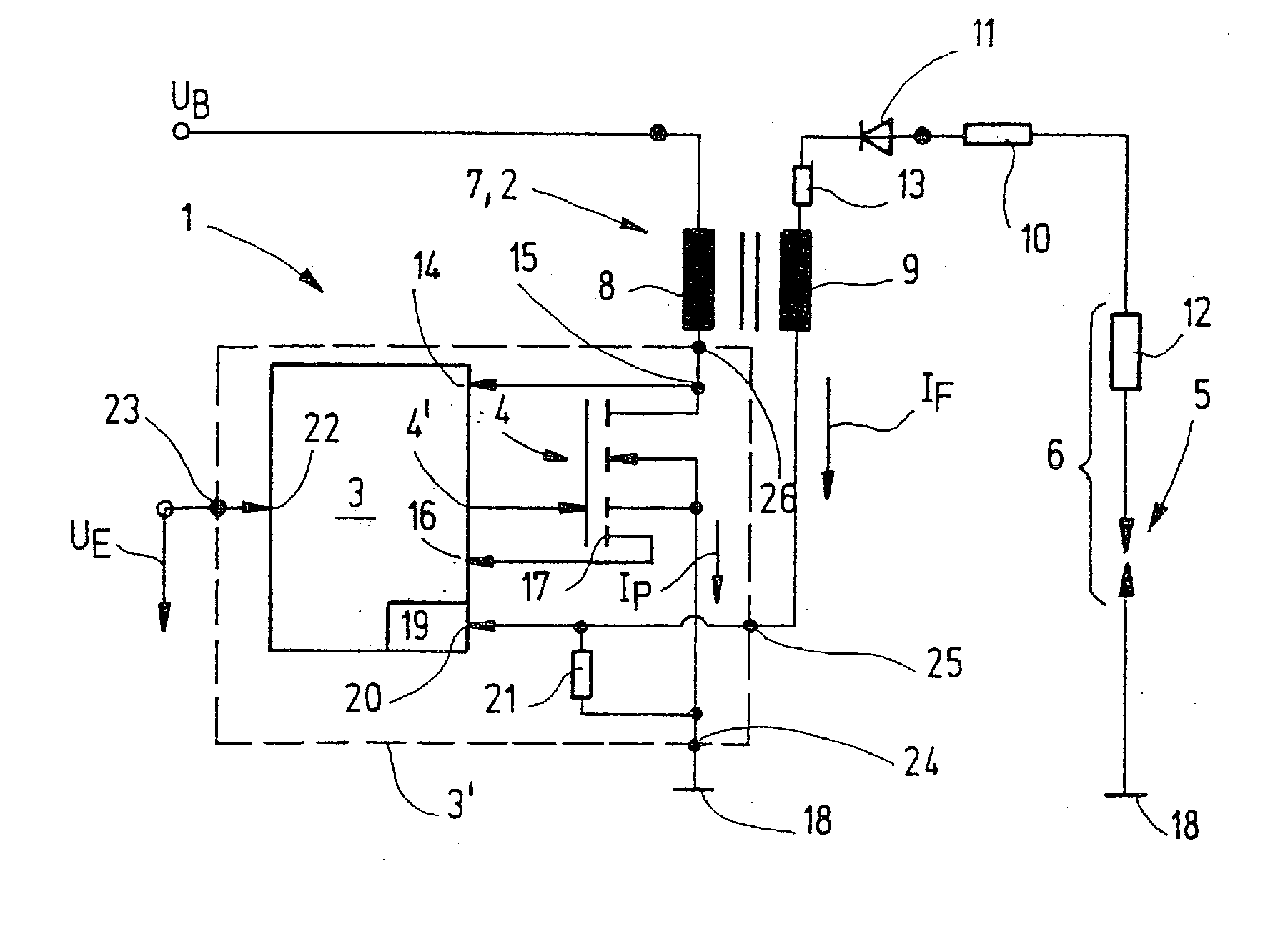

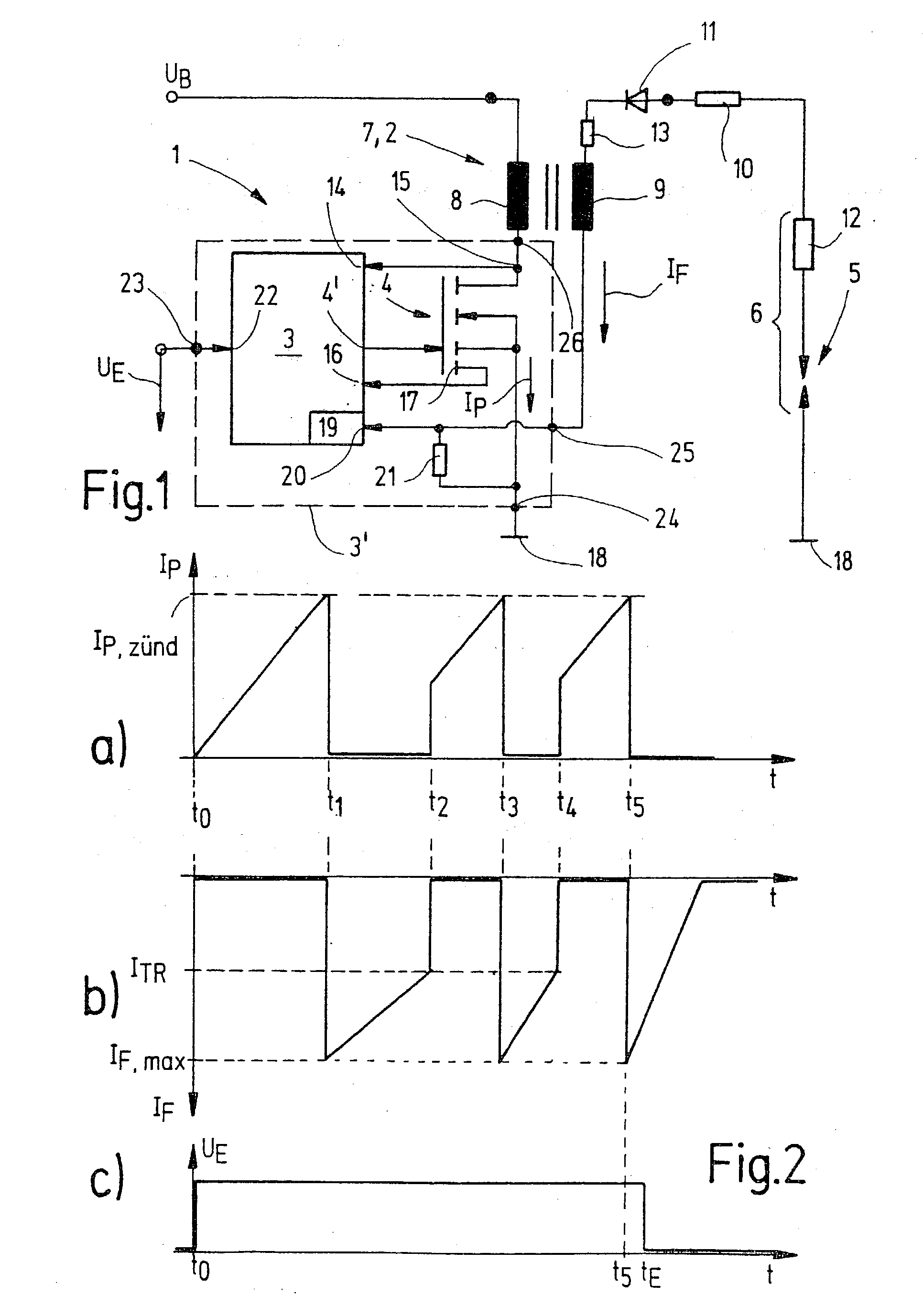

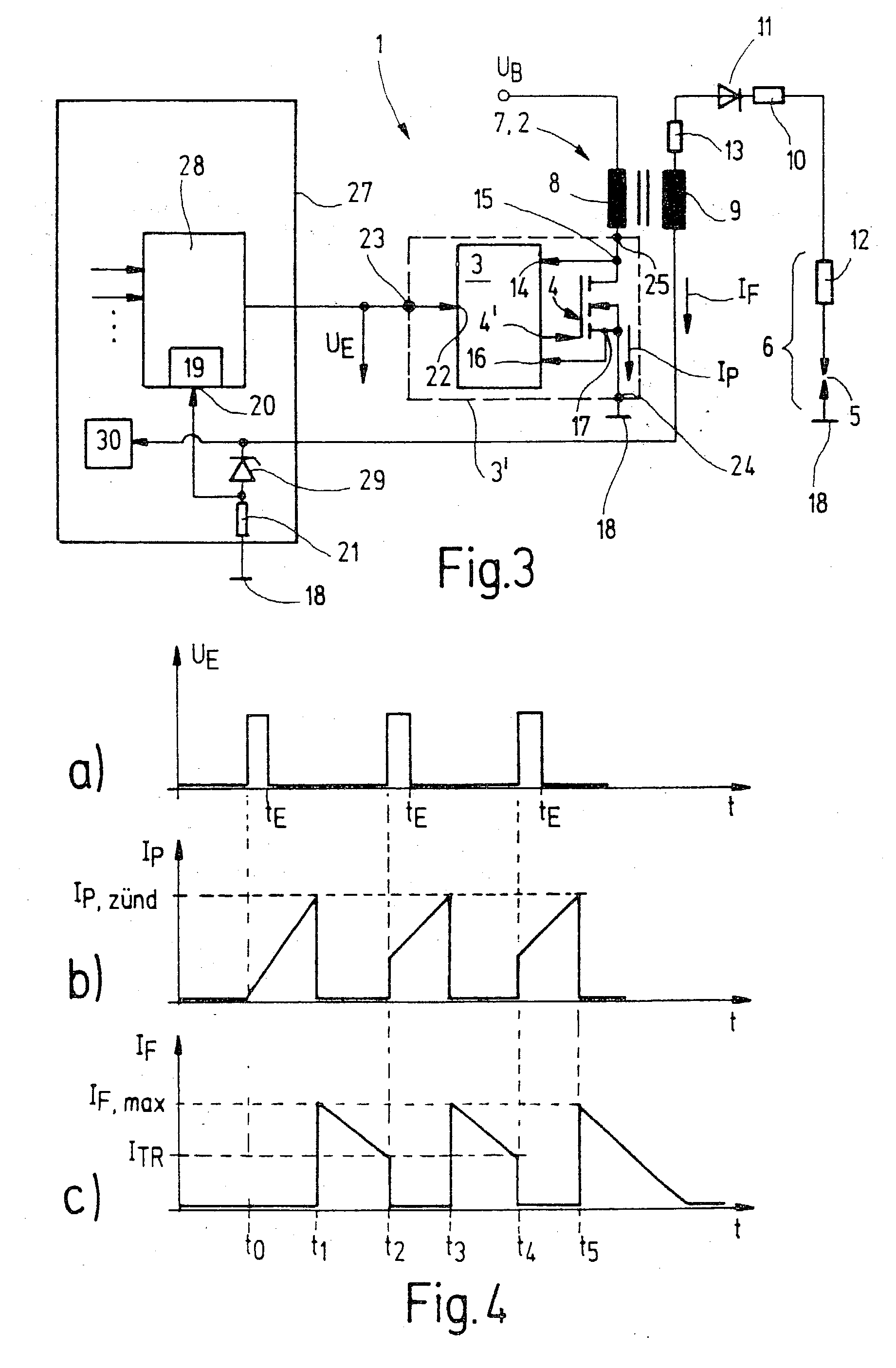

Method for producing a sequence of high-voltage ignition sparks and high-voltage ignition device

InactiveUS20030089355A1Reduce capacitanceShorten charging timeElectric spark ignitersMachines/enginesHigh pressureEnergy storage

A method of generating a sequence of high-voltage ignition sparks is described, wherein an ignition energy storage device (2) is charged up to a specifiable charge state (IP, ZÜND), by a discharge of the ignition energy storage device (2), a spark is generated on an ignition spark generating means (6) connected to the ignition energy storage device (2), a recharging operation of the ignition energy storage device (2) is started before the ignition energy storage device (2) is completely discharged, and by discharging the ignition energy storage device (2), an additional ignition spark is generated on the ignition spark generating means (6).

Owner:ROBERT BOSCH GMBH

Ni-Cr alloy thin film igniter with low ignition voltage and preparation method thereof

InactiveCN102384486AIncrease reaction rateAchieve mass productionCombustion ignitionNi cr alloyOptoelectronics

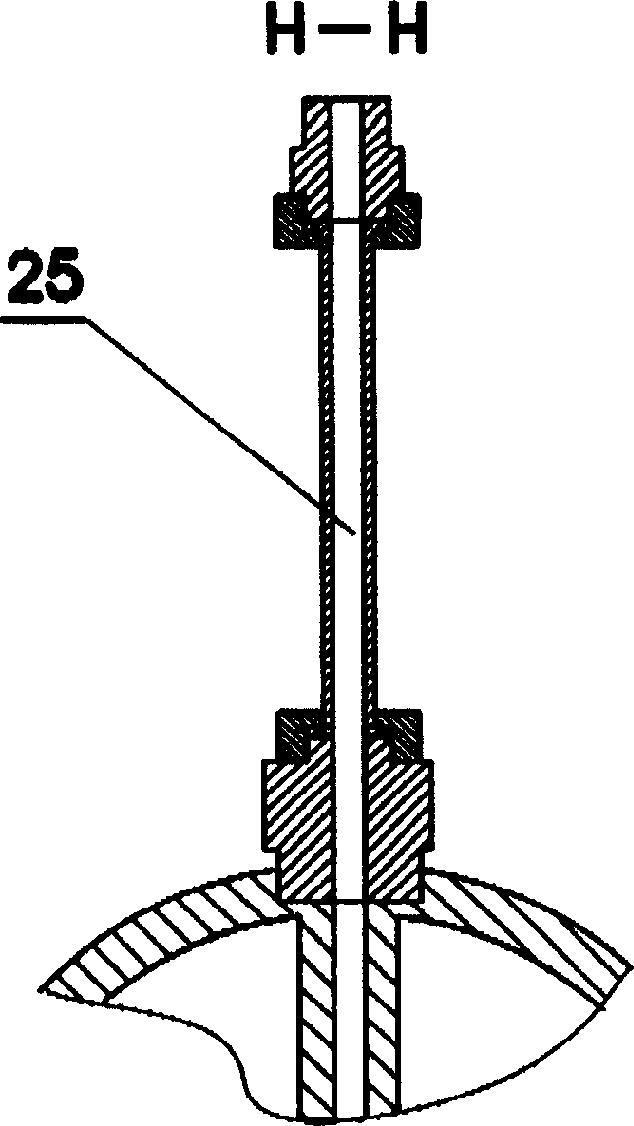

The invention discloses a Ni-Cr alloy thin film igniter with a low ignition voltage and a preparation method thereof and belongs to the technical field of a priming system. The Ni-Cr alloy thin film igniter with the low ignition voltage comprises a base; an isolating film is arranged on the base; an igniting element is arranged on the isolating film; the igniting element is provided with a bonding pad area of an igniter lead wire; and the igniting element is made of Ni-Cr alloy. According to the preparation method provided by the invention, the igniter is prepared by using a micro-machining technology. In the Ni-Cr alloy thin film igniter, the ignition is reliably realized at a lower ignition voltage; the ignition voltage is as low as 4.8 V / 10 muF and the ignition energy is as low as 100 mJ; and the shake-proof performance is good.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

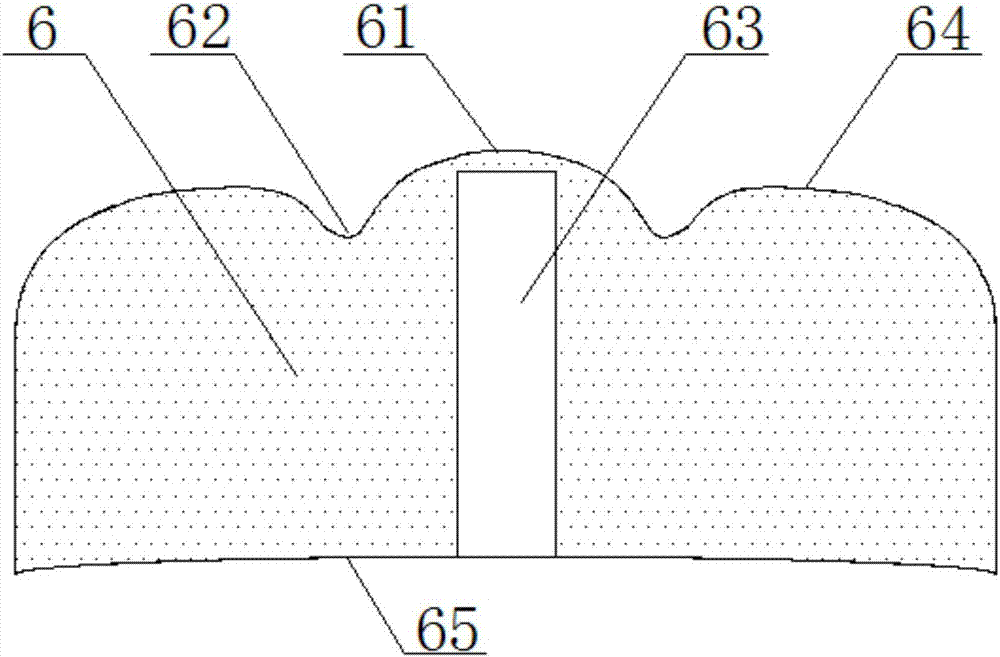

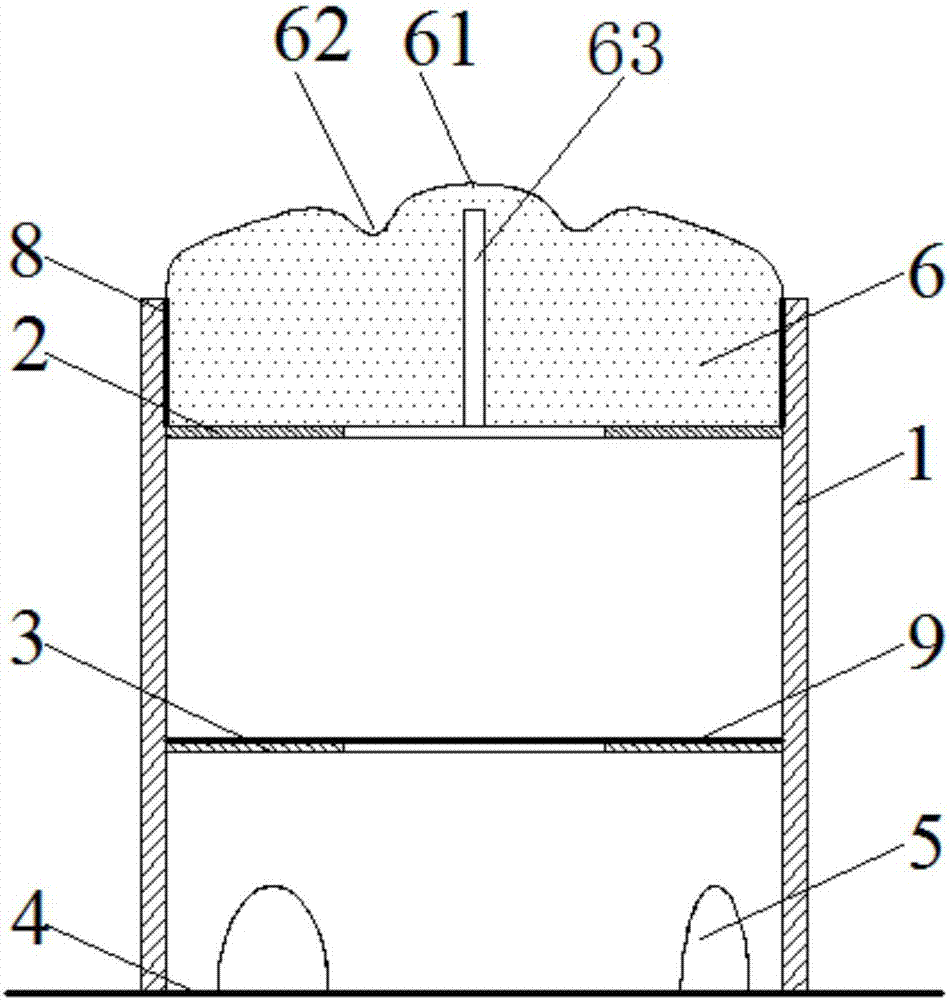

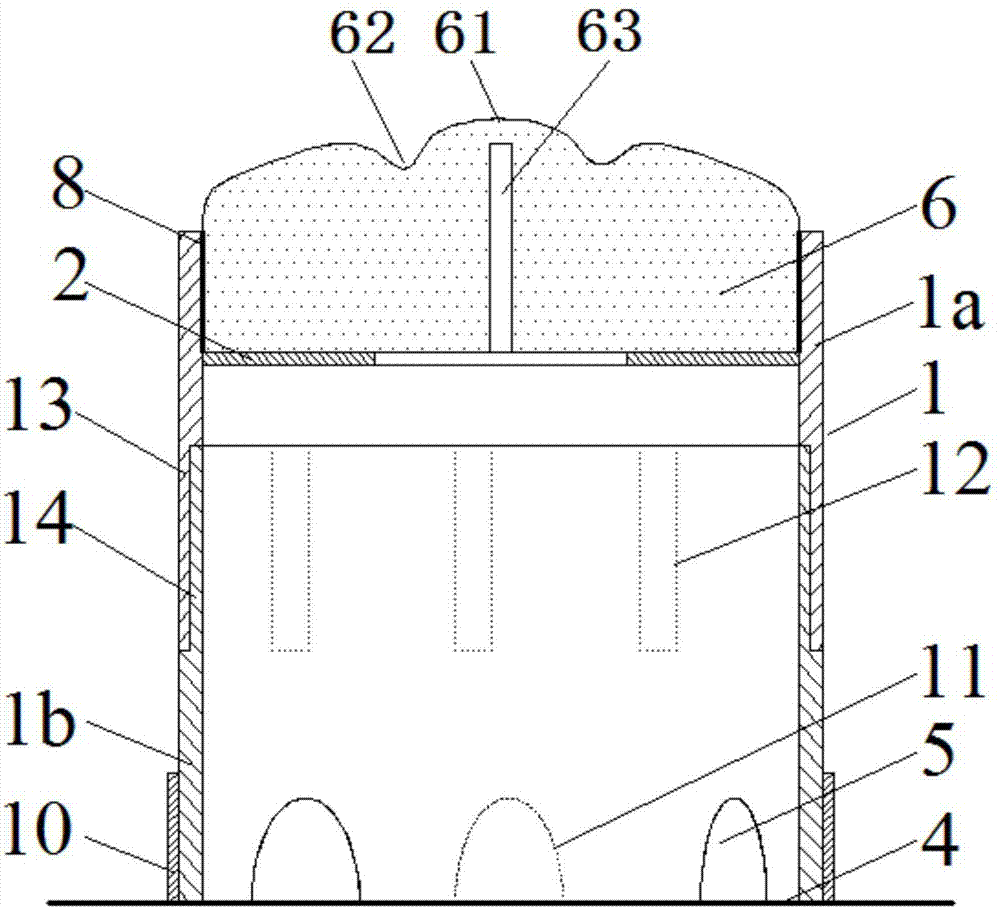

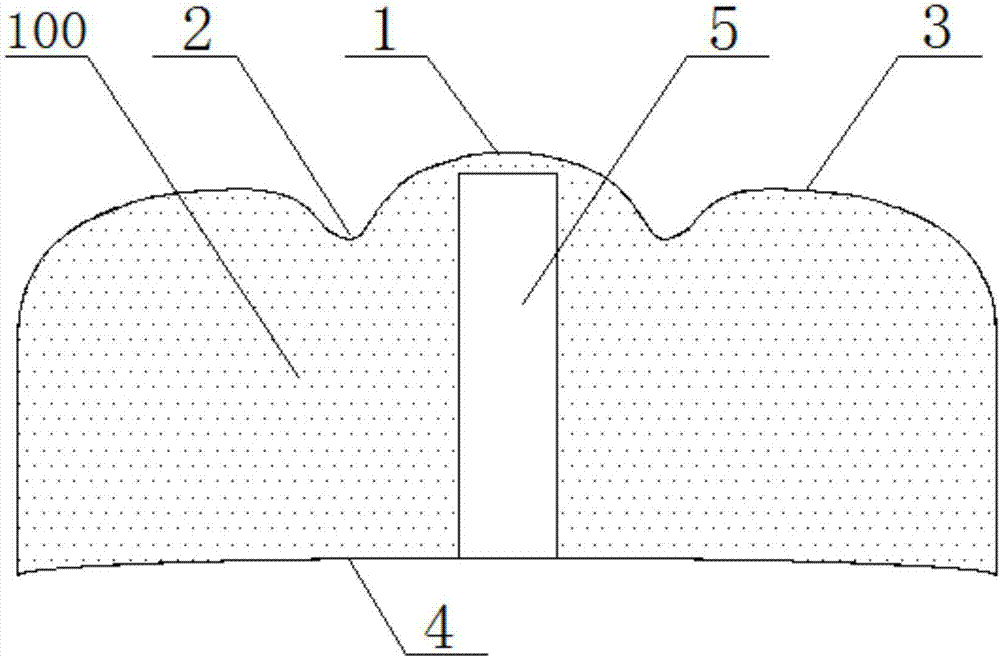

Moxa-moxibustion tool and preparation process thereof

ActiveCN107280965AAdvantages of preparation processWon't fallDevices for heating/cooling reflex pointsPharmaceutical product form changeEngineeringMaximum size

The invention relates to a moxa-moxibustion tool and a preparation process thereof. The moxa-moxibustion tool comprises a moxibustion tool and a moxibustion core, wherein an air hole is formed in the bottom end of the moxibustion tool, the moxibustion tool is of a cylindrical structure, the moxibustion core is fixed to the upper portion of the inner cavity of the moxibustion tool, the upper surface of the moxibustion core protrudes out of the moxibustion tool, and the portion, in contact with a moxa cake, of the inner surface of the moxibustion tool is a flame-retardant face and is of a wedge surface structure. The moxibustion core is the moxa cake, the maximum size of the bottom surface of the moxa cake is 1-5 times of the height of the moxa cake, the bottom surface of the moxa cake is a cambered surface protruding upwards, the center of the upper surface of the cambered surface protrudes and is higher than the upper surface of the cambered surface, the bottom surrounding of the protrusion is downwards sunken and is lower than the upper surface of the moxa cake, a blind hole with a downward opening is formed in the moxa cake, and the hole bottom of the blind hole is located in the protrusion. The invention also correspondingly provides the preparation process of the moxa-moxibustion tool. The moxa-moxibustion tool is aligned during the moxa cake releasing, releasing and installation of the moxa cake can be simultaneously achieved, and working processes are saved. A central hole of the moxa cake is the blind hole, and the blind hole blocks an upper-end outlet of a flue, so that moxibustion smoke only flows downward, and the moxibustion utilization rate is improved.

Owner:湖北蕲艾堂科技有限公司

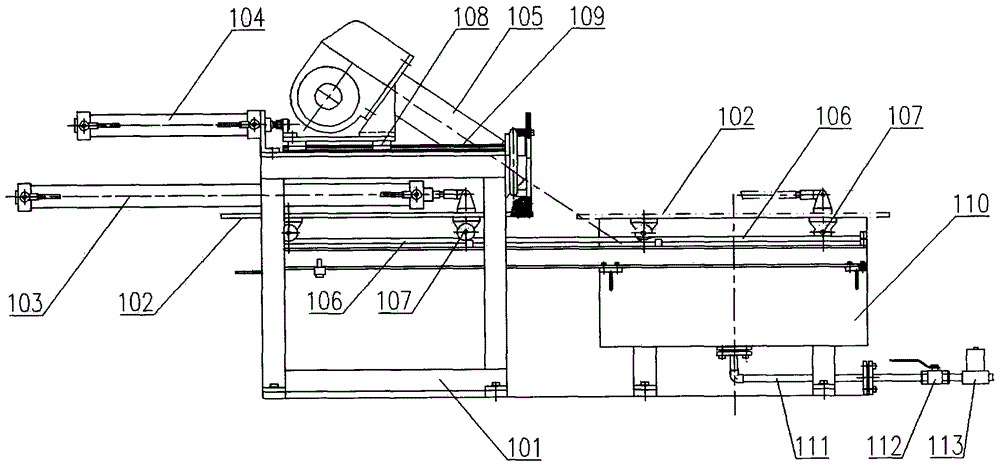

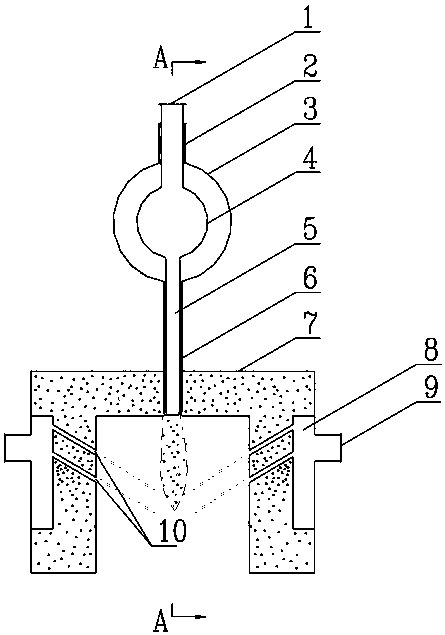

Ignition device for biomass gasification furnace and using method thereof

InactiveCN101726002APromote combustionImprove ignition success rateIncandescent ignitionCombustible gas productionElectricityEngineering

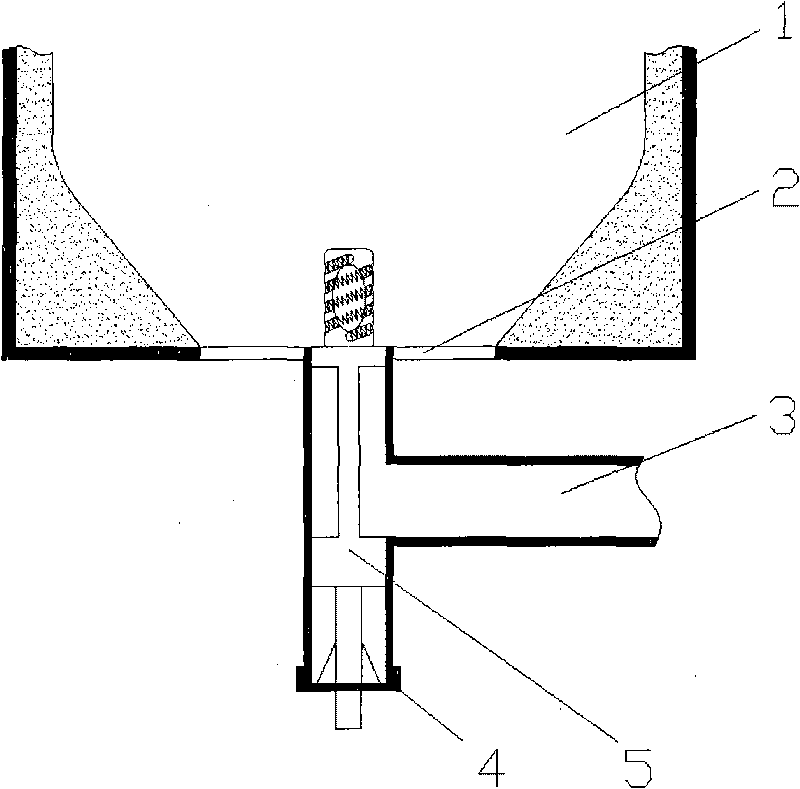

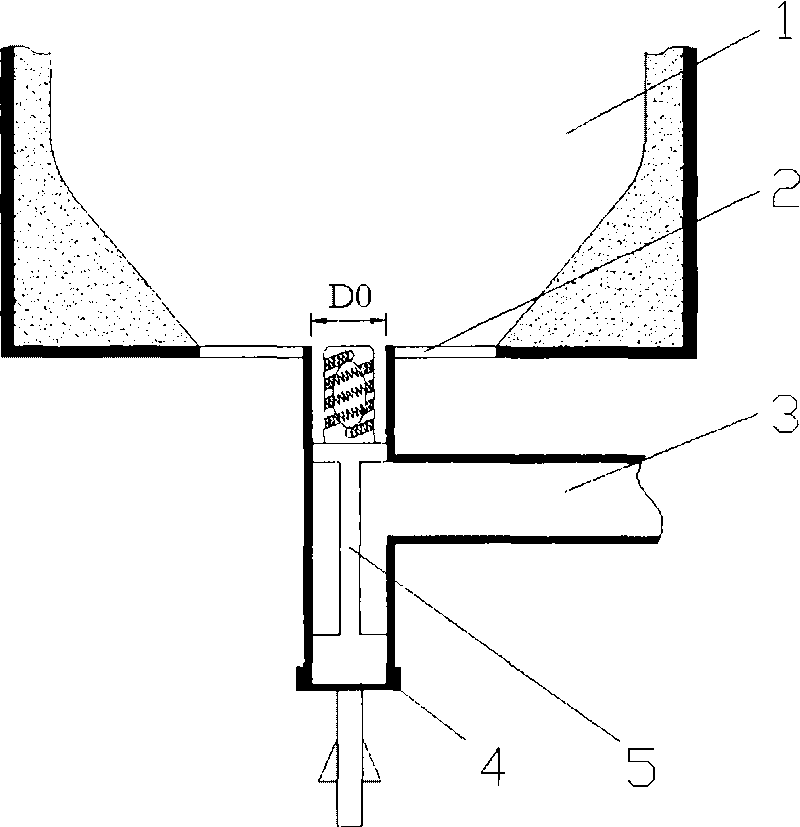

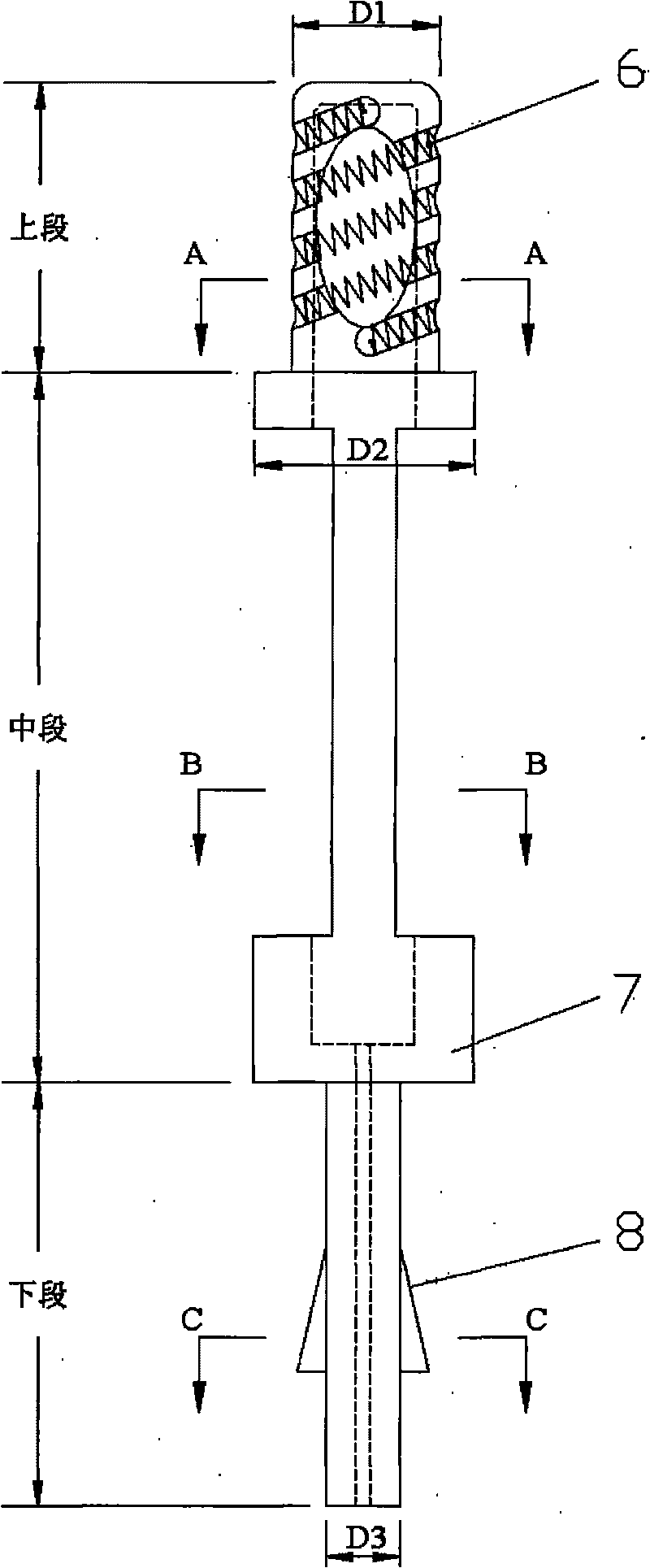

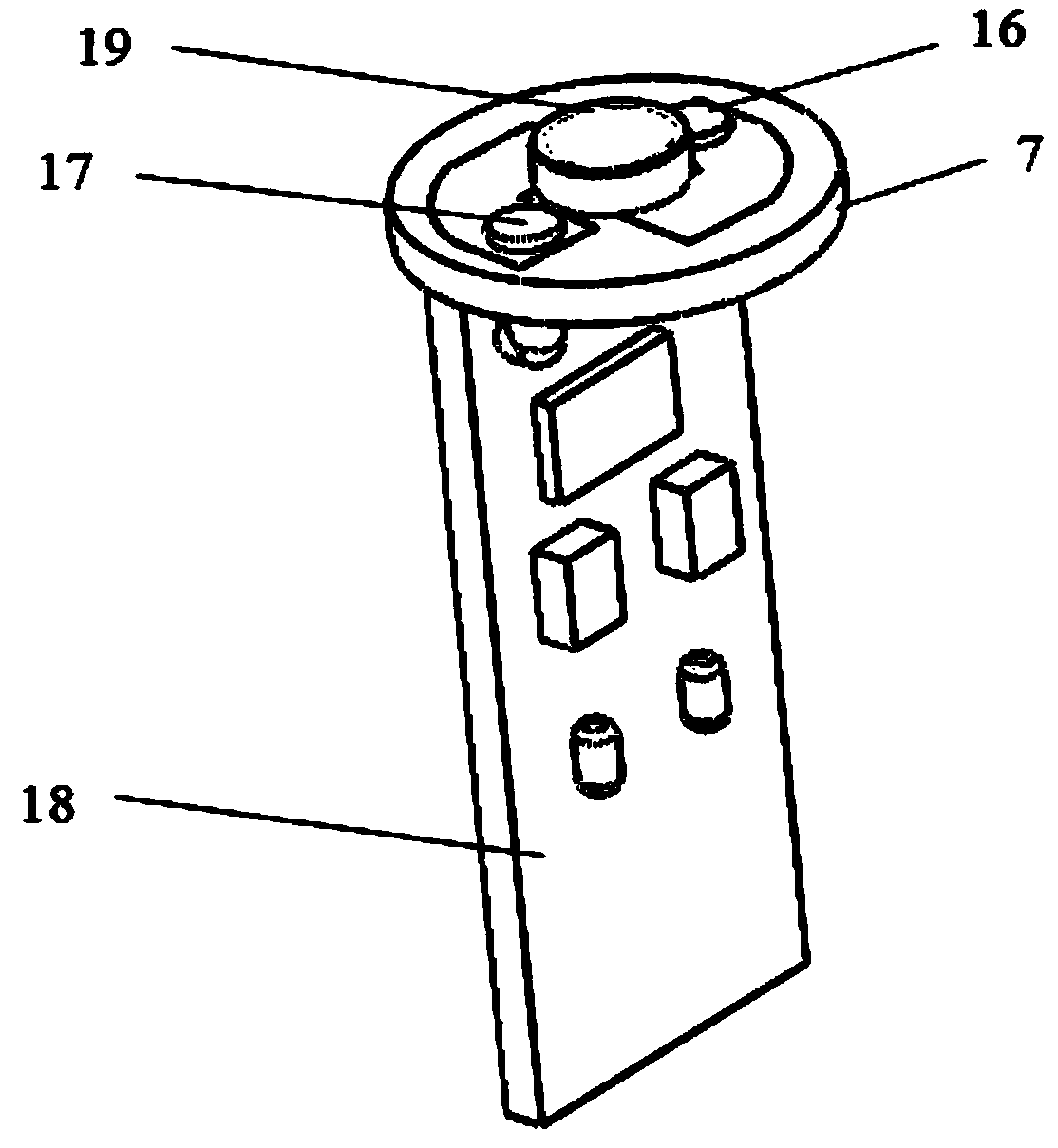

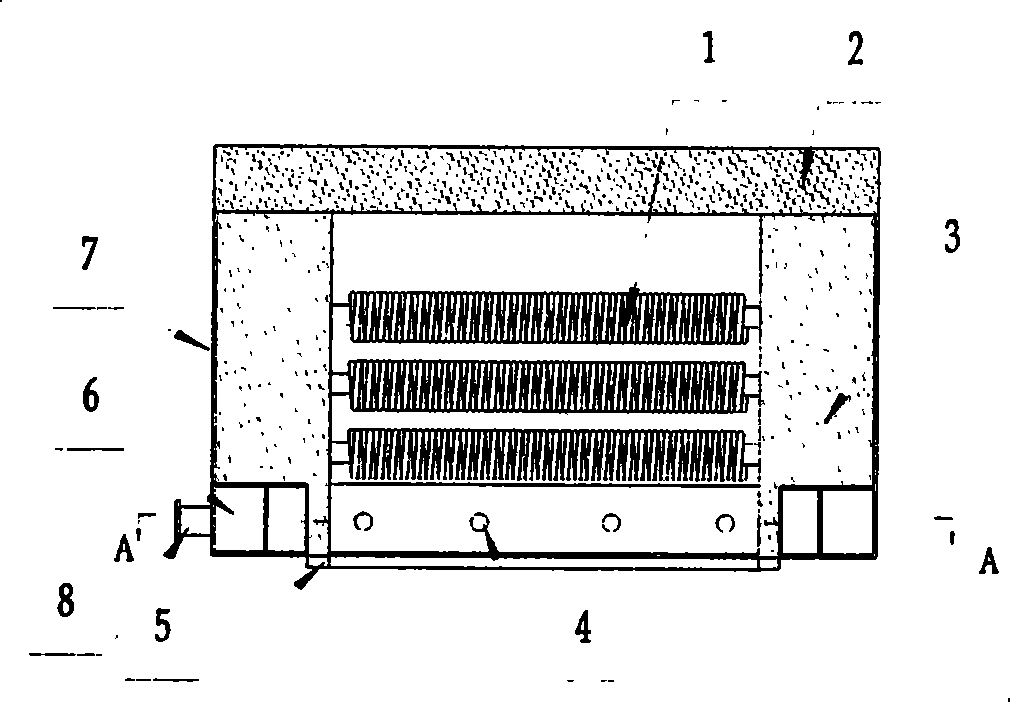

The invention relates to an ignition device for a biomass gasification furnace and a using method thereof. In the device, an ignition bar formed by a heating wire and a ceramic tube element is vertically arranged in a three-way inlet tube of the biomass gasification furnace; the upper end of the ceramic tube element wound with the heating wire is positioned above a grate; the biomass gasification furnace are filled by granular biomass materials and compacted; the biomass materials are closely contacted with the heating wires; after the ignition bar is electrified, the biomass materials at the periphery of the ignition bar is directly heated; a draught fan is opened after 10 to 20 seconds of heating, air is introduced to the bottom of the gasification furnace from the lateral side of the upper section of the ignition bar; the power supply of the ignition bar is closed after the electrification lasts for 10 to 20 seconds; and the ignition bar is twitched downwards and is rotated to ensure that the ignition bar is retracted inside the three-way inlet tube, the ignition bar is separated from the biomass material subjected to high-temperature gasification reaction with the ignition bar, and the air is introduced into the biomass gasification furnace from clearance between the upper end of the ignition bar and the inlet tube to maintain constant performance of the gasification reaction. The ignition device has the advantages of high success rate of ignition, short ignition time, simple and convenient operation and safe use.

Owner:JIANGSU UNIV +1

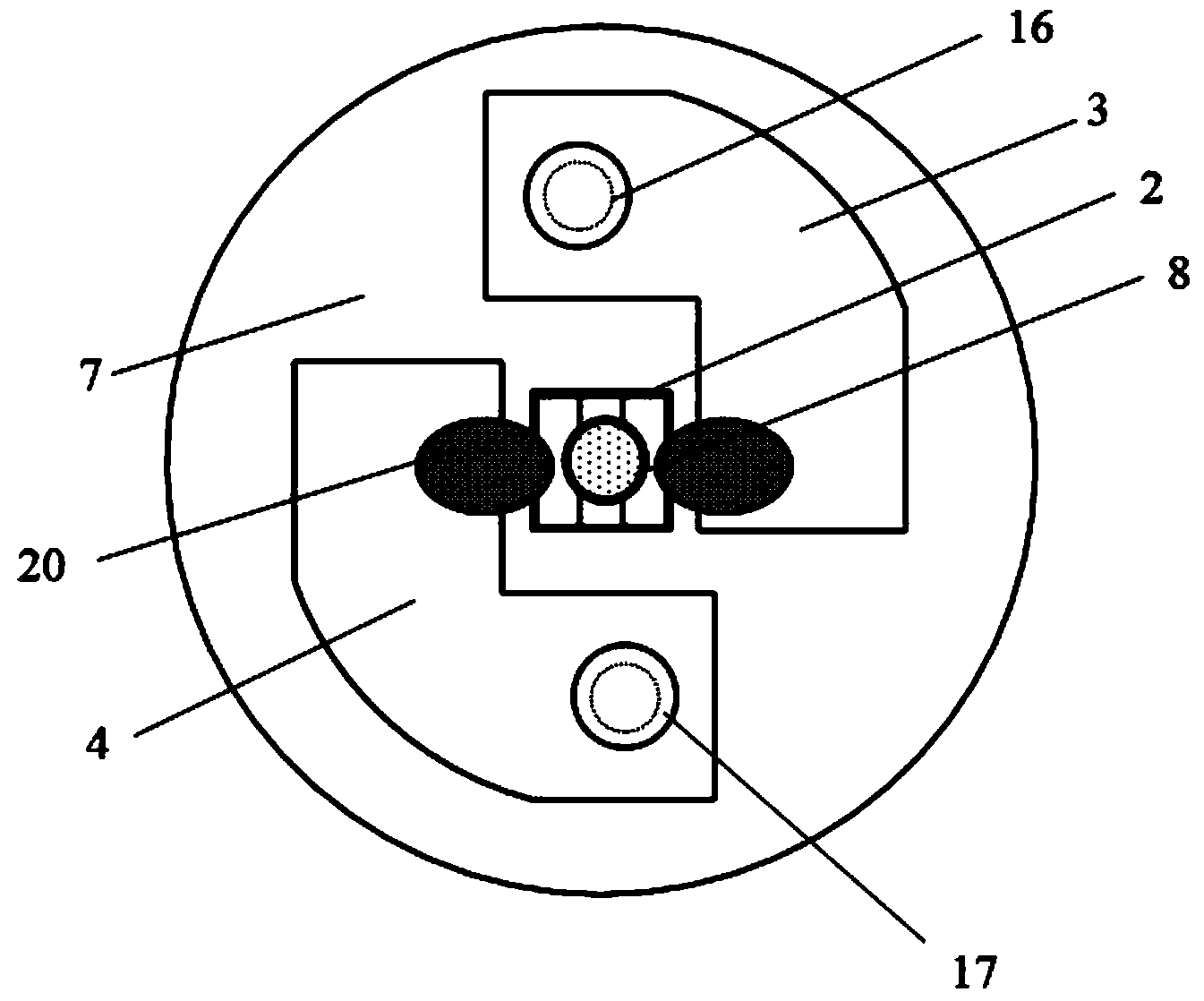

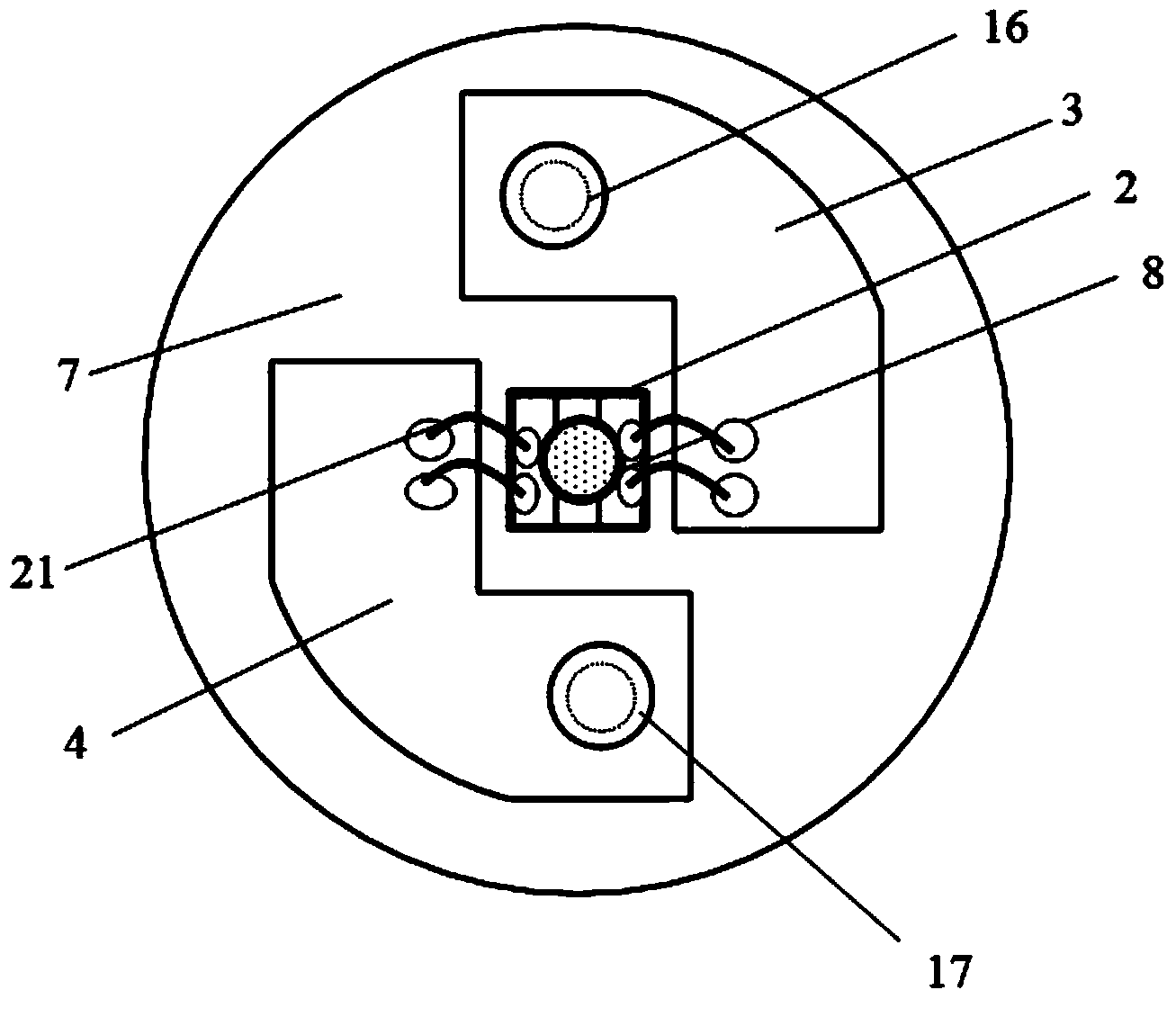

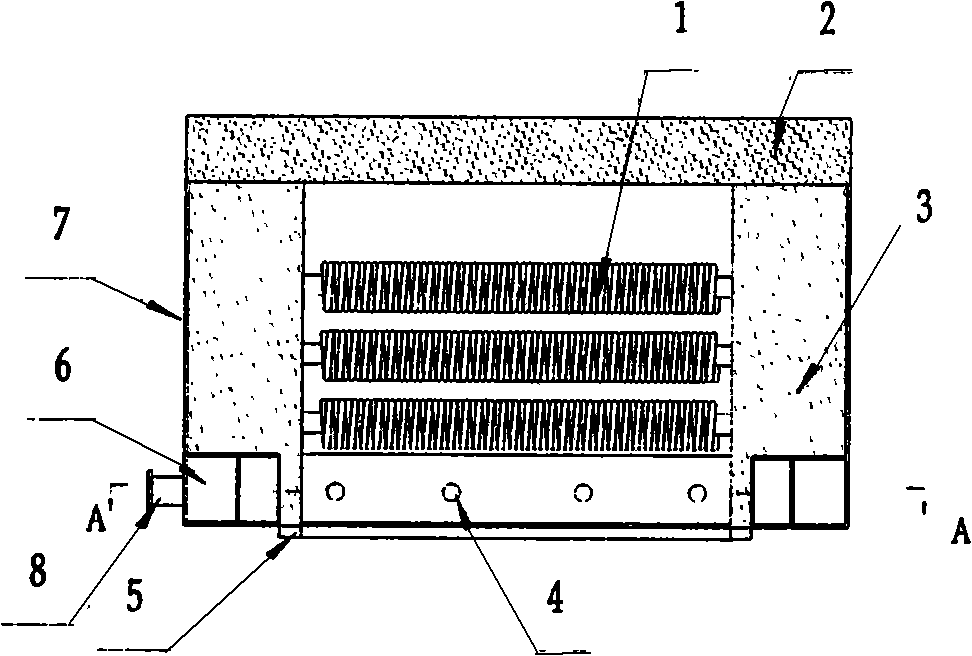

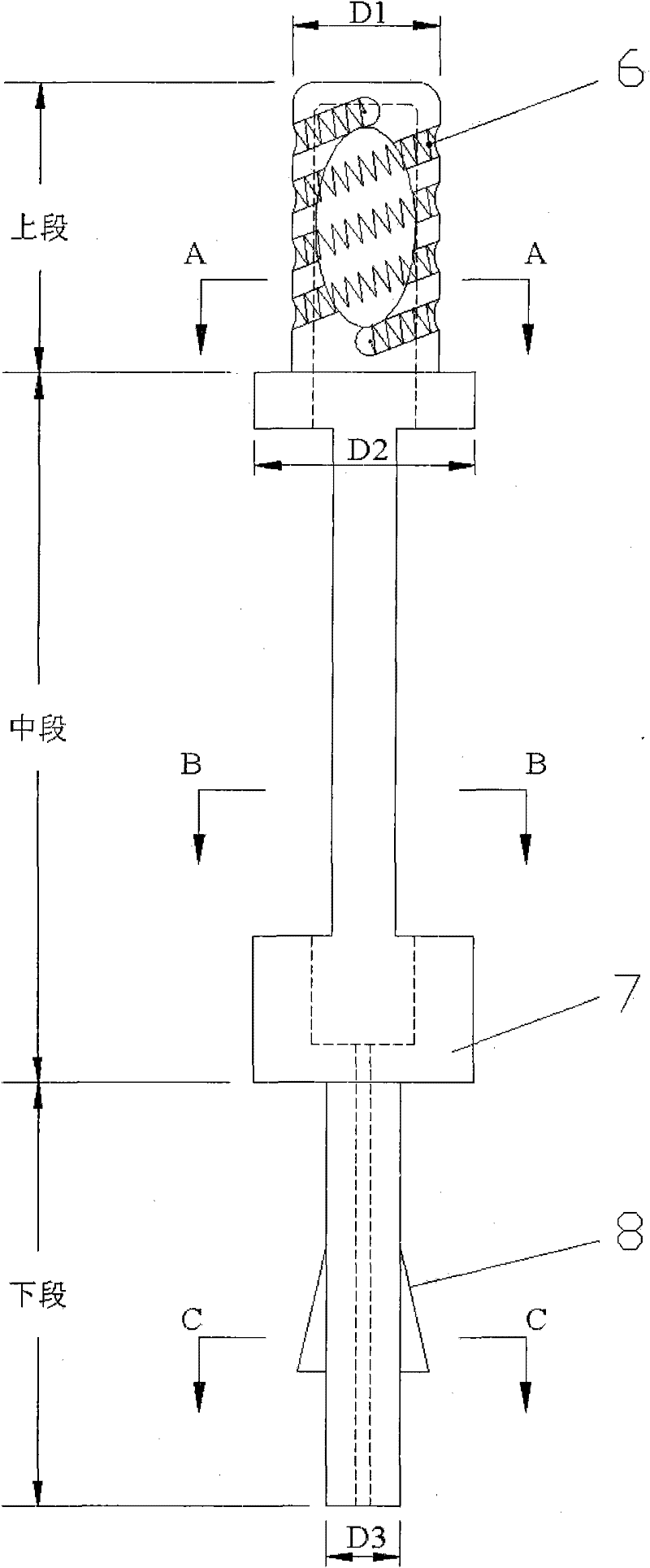

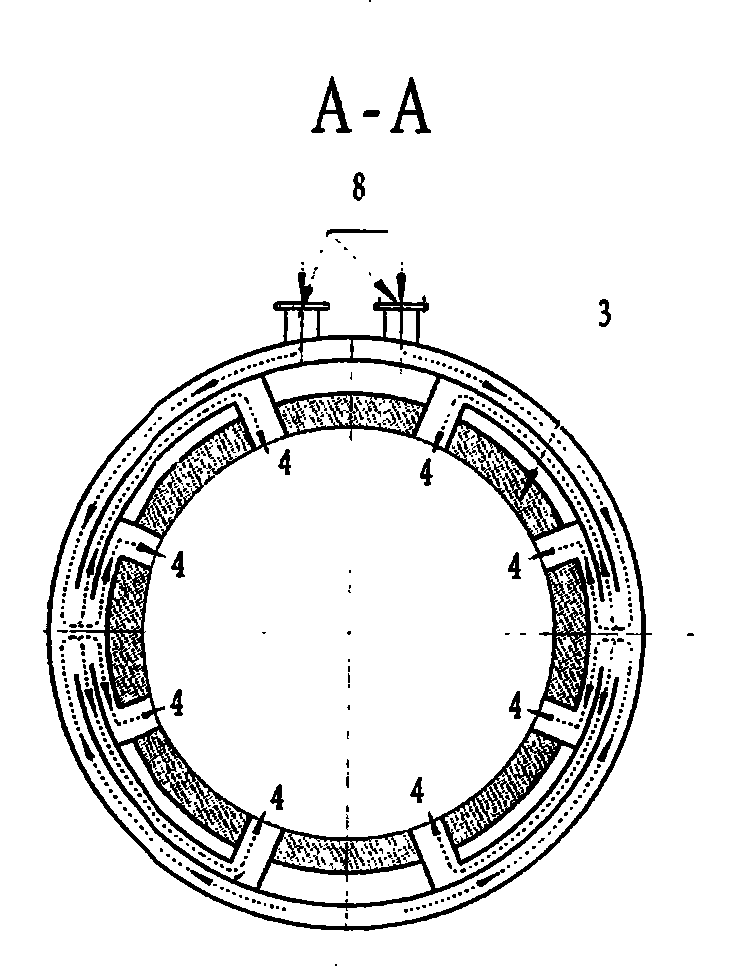

PCB (printed circuit board) type low-voltage semiconductor-bridge ignition assembly

The invention relates to a PCB (printed circuit board) type low-voltage semiconductor-bridge ignition assembly which comprises a semiconductor-bridge transducer chip, an ignition charge, a main circuit board and a PCB. The main circuit board and the PCB form a T-shaped circuit board connection structure. The semiconductor-bridge transducer chip is fixed to the PCB through conducting resin or bonding wires. The ignition charge is packaged through a plastic sleeve. A pair of horse-head-shaped copper discharge plate structures with saw teeth covers the back of the PCB; each of the discharge plates is provided with at least two saw teeth facing the circumference; the saw teeth are of angle of 50-80 degrees. The ignition assembly can meet requirements of low ignition voltage, high electromagnetism safety, short ignition time, small size, firm structure and the like.

Owner:北京理工北阳爆破工程技术有限责任公司

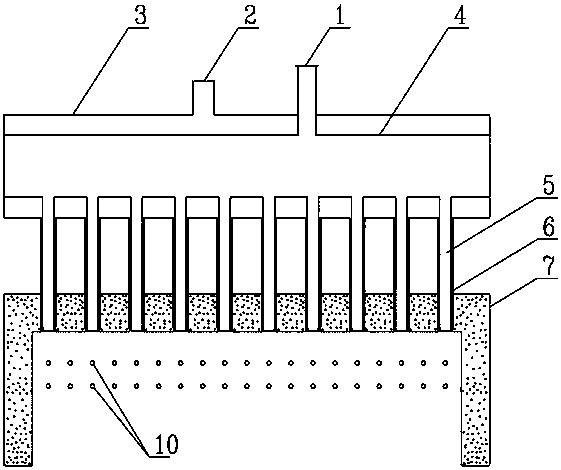

Ignition method and apparatus of product line for sintering porcelain granule

InactiveCN101269949AImprove ignition efficiencySimple structureClaywaresProduction lineThermal energy

The present invention relates to an ignition method and an ignition device, which are applied to the baking porcelain grain production line. The ignition method: the temperature of the ignition device is increased to pre-determined temperature, generally 800 to 1350 DEG C, a baking box that is fully provided with the baking raw materials is close to the ignition device at high temperature to reach the closed state, and then to be preheated; the baking box is ventilated with air or other combustion-assistant gas to assist the combustion, so that the surface of the raw materials can be combusted adequately; the temperature in the ignition device is introduced downwards by the guiding air so as to increase the thickness of the ignition layer; the air introduction is stopped after the ignition, and the ignited baking box is moved to a next position, and simultaneously the next baking box that is fully provided with the baked raw materials is moved to the ignition position. With the present invention, the ignition efficiency at the surface of the baking box is high, thereby greatly reducing the heat waste and shortening the ignition time; moreover, the porcelain grain that is arranged on the surface of the baking box is combusted adequately without breaking or dust; the particle is complete, thus improving the rate of the finished product of the production line. The ignition device has simple structure, not only has low production cost, but also greatly reduces the running operation compared with the traditional ignition system.

Owner:BEIJING SIDIQI SCI & TECH

Moxa cake and preparation process thereof

InactiveCN107280964AImprove AI utilizationWon't fallDevices for heating/cooling reflex pointsPharmaceutical product form changeFlueEngineering

The invention relates to a moxa cake and a preparation process thereof. The moxa cake is formed by pressing moxa, the whole moxa cake is cake-shaped, the maximum size of the bottom surface of the moxa cake is 1-5 times of the height of the moxa cake, the center of the upper surface of the moxa cake protrudes and is higher than the upper surface of the moxa cake, the bottom surrounding of the protrusion is downwards sunken and is lower than the upper surface of the moxa cake, a blind hole with a downward opening is formed in the moxa cake, and the hole bottom of the blind hole is located in the protrusion. The preparation process incudes a cold-press method or a hot-press method. A central hole of the moxa cake is the blind hole, the hole bottom of the blind hole is located in the protrusion of the moxa cake and is higher than the upper surface of the moxa cake, the blind hole is kept unchanged at a preliminary burning stage, moxa produced during moxa burning covers the hole bottom when the hole bottom of the blind hole is burned, so that the inside of the moxibustion smoke is always the blind hole, the upper end blocking a flue of the blind hole is opened, the moxa smoke only flows downward, and the moxibustion utilization rate is improved.

Owner:湖北蕲艾堂科技有限公司

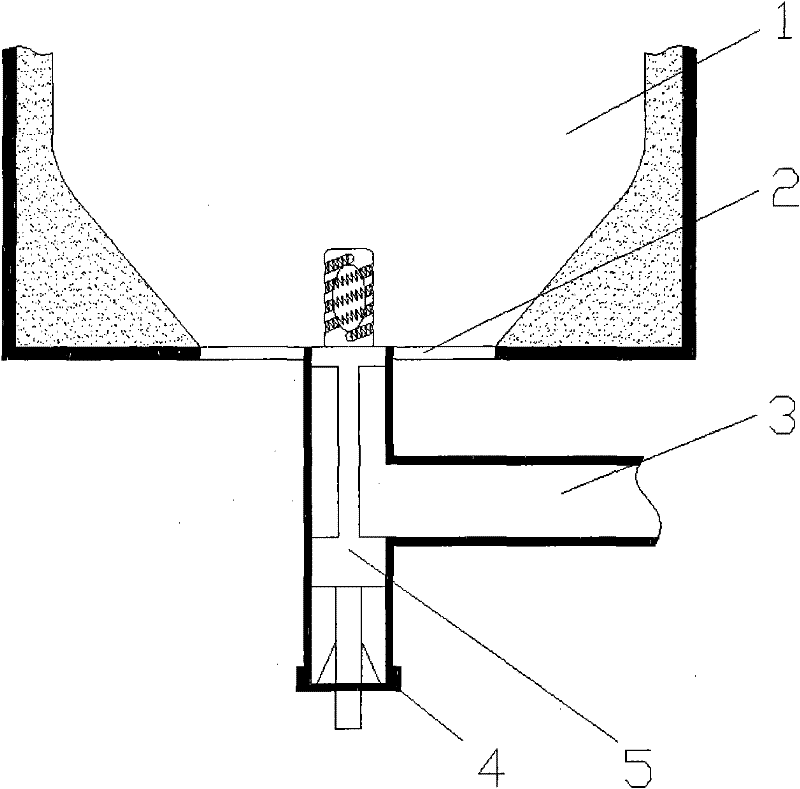

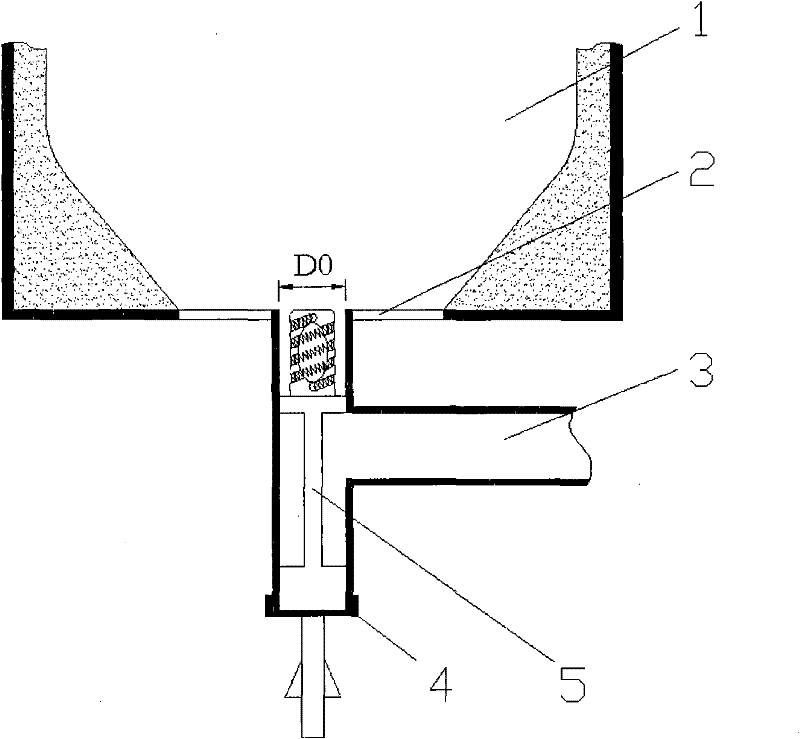

Ignition destroy bomb and preparation method thereof

InactiveCN105674828AReasonable structural designImprove acceleration performanceBlasting cartridgesBlastingEngineeringFrustum

The invention provides an ignition destroy bomb and a preparation method thereof. The ignition destroy bomb comprises an outer shell body, a jet nozzle, a tubular powder column and a seal cap, wherein the jet nozzle, the tubular powder column and the seal cap are sequentially arranged inside the outer shell body from bottom to top. The outer shell body includes an upper cylindrical portion and a lower conical frustum portion. The jet nozzle is arranged inside the conical frustum portion of the outer shell body. Furthermore, the external surface of the jet nozzle abuts against the internal wall of the conical frustum portion. A cylinder-shaped inner shell body is arranged inside the cylindrical portion of the outer shell body and abuts against the internal wall of the cylindrical portion. The powder column is loaded inside the inner shell body. The powder column includes a main powder charging column and an igniting powder column, wherein the bottom end face of the main powder charging column is a conical surface protruding outwards, and the conical surface is attached to the top portion of the jet nozzle closely; the igniting powder column is loaded in an inner cavity of the main powder charging column, and the length of the igniting powder column is equal to that of the main powder charging column; and two pieces of seal paper are stick on the upper end face of the main powder charging column and the lower end face of the igniting powder column respectively. By means of the ignition destroy bomb, unexploded bombs can be destroyed fast, safely and efficiently.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

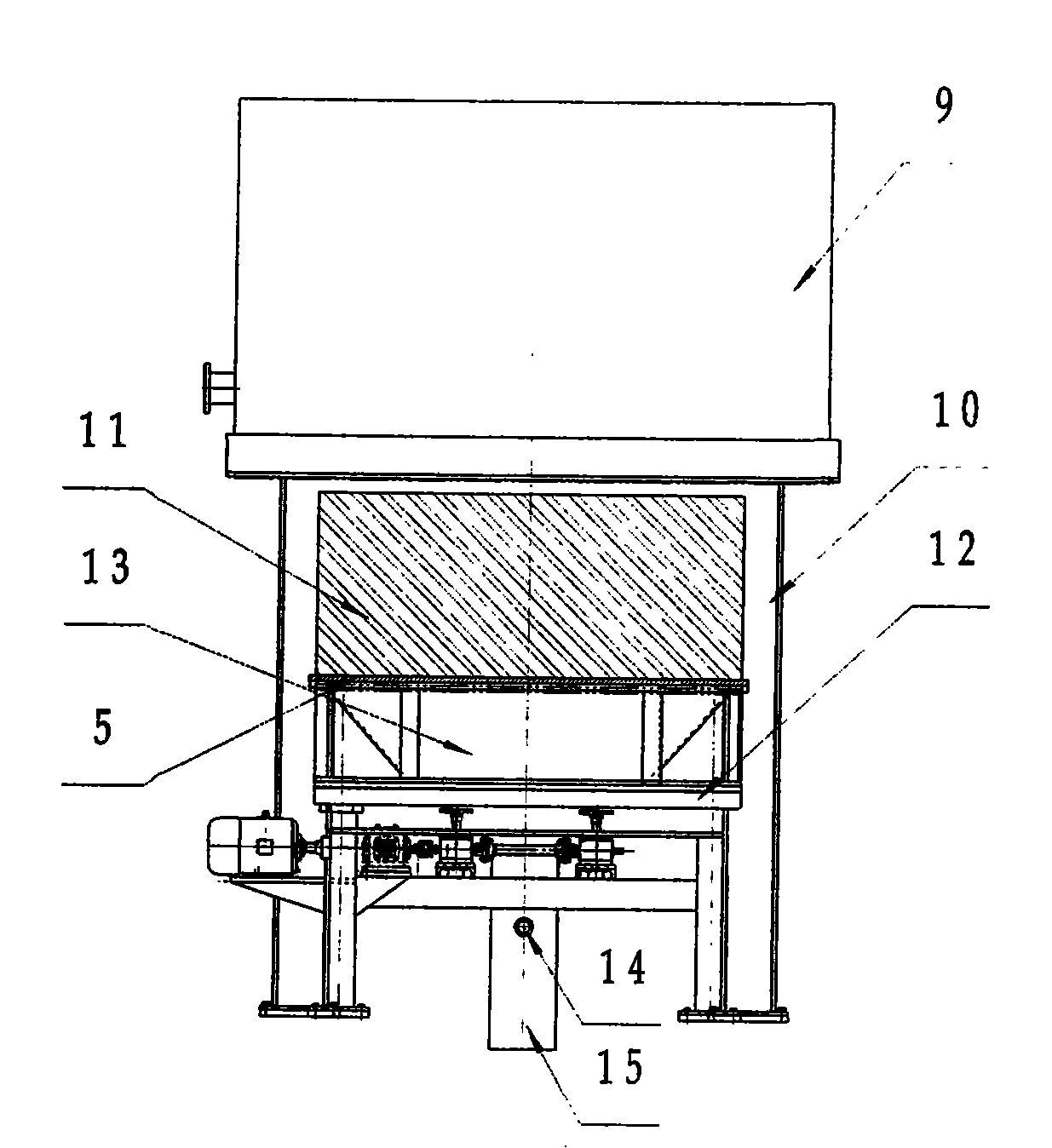

Large biomass boiler

InactiveCN109140518AShort ignition timeImprove efficiencyLighting and heating apparatusStove/ranges for heating waterHearthBiomass boiler

The invention discloses a large biomass boiler which comprises a boiler body. The large biomass boiler further comprises a hearth, a boiler circle, an ash discharge device, an ash collection box, a stock bin, a spiral feeding device, a waste heat recycling chamber, a waste heat water tank, a first smoke dust filter device, a second smoke dust filter device, a first fan, a second fan, a third fan and a controller which are matched with the boiler body and assembled into a whole. A fire stop ring is arranged above the hearth and located below the boiler circle, a fire grate is arranged inside the hearth, and the lower end of the hearth is provided with an ash discharge hopper. Smoke residual heat is utilized more sufficiently, the waste heat utilization efficiency is improved, the efficiencyis high, energy is saved, waste gas is exhausted after being filtered to reach standards, environmental protection is better, fuel ignition time is shorter, ash removal operation can be automaticallycompleted, manual treatment is not needed, the working efficiency is high, biomass fuel combustion is more sufficient, and combustion time is longer.

Owner:无锡晶瑜智能机械有限公司

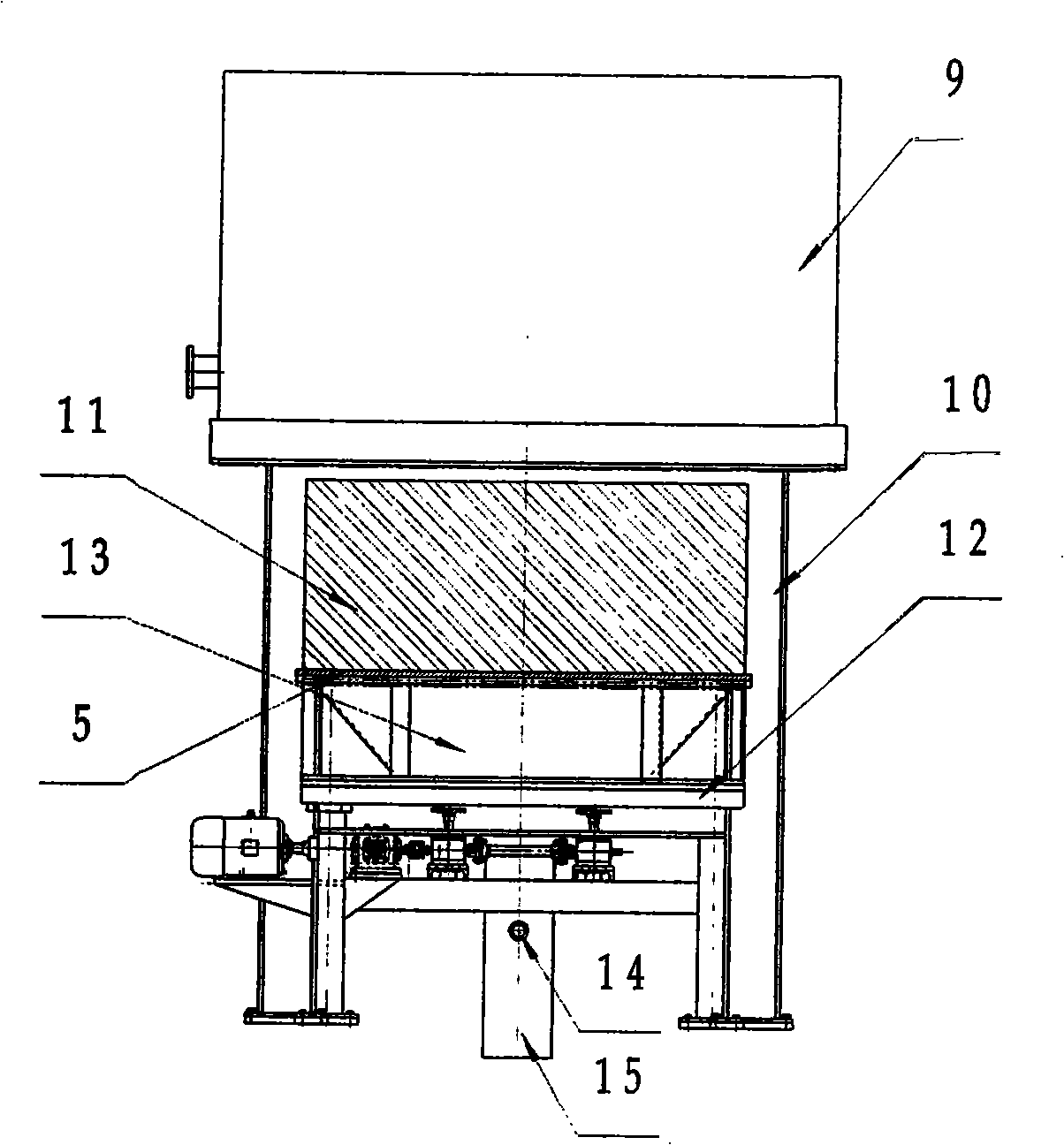

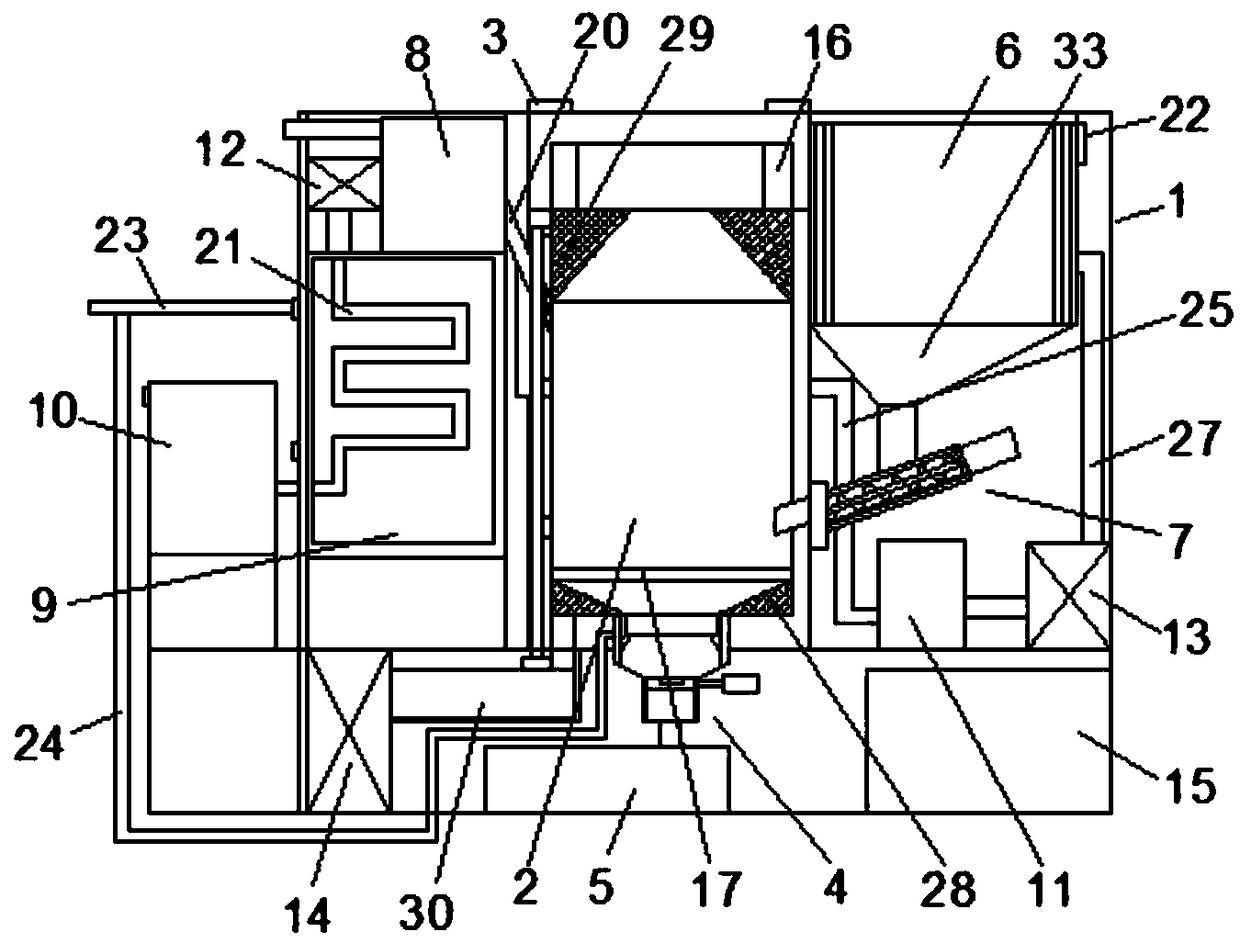

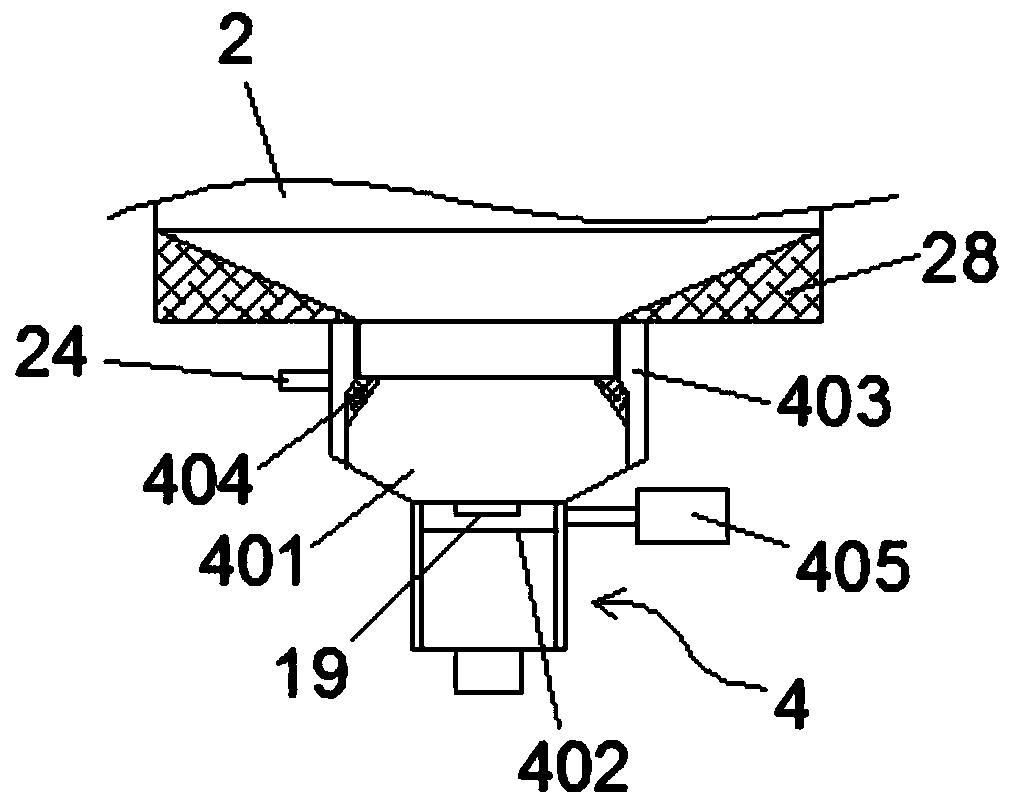

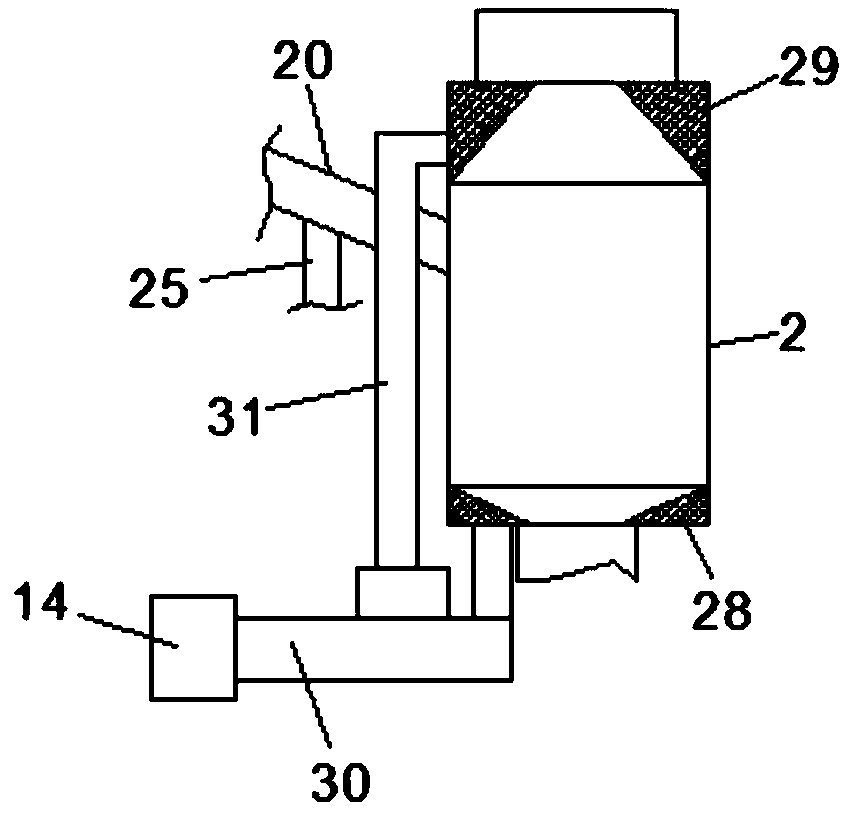

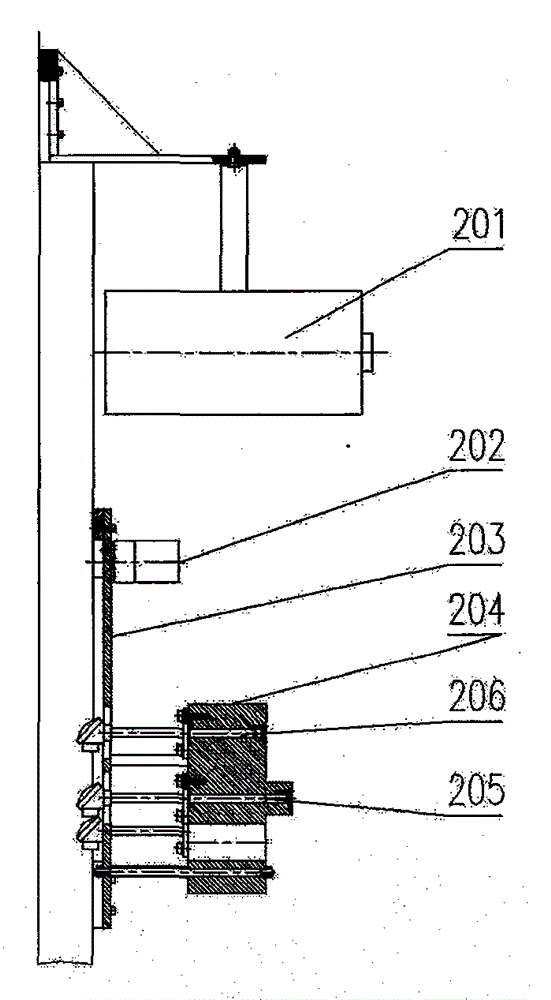

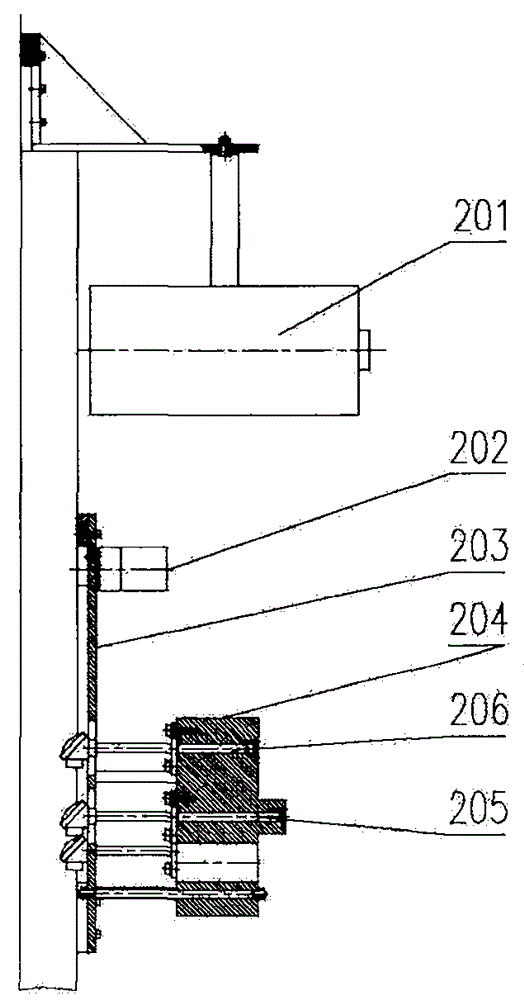

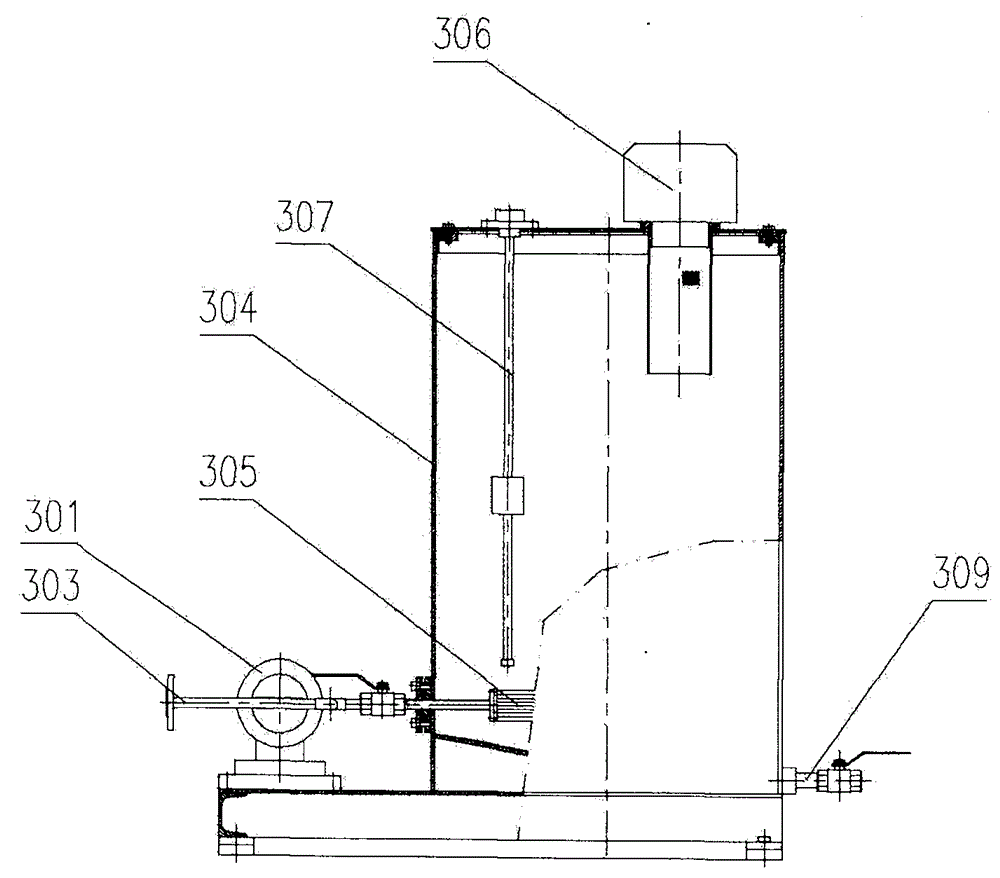

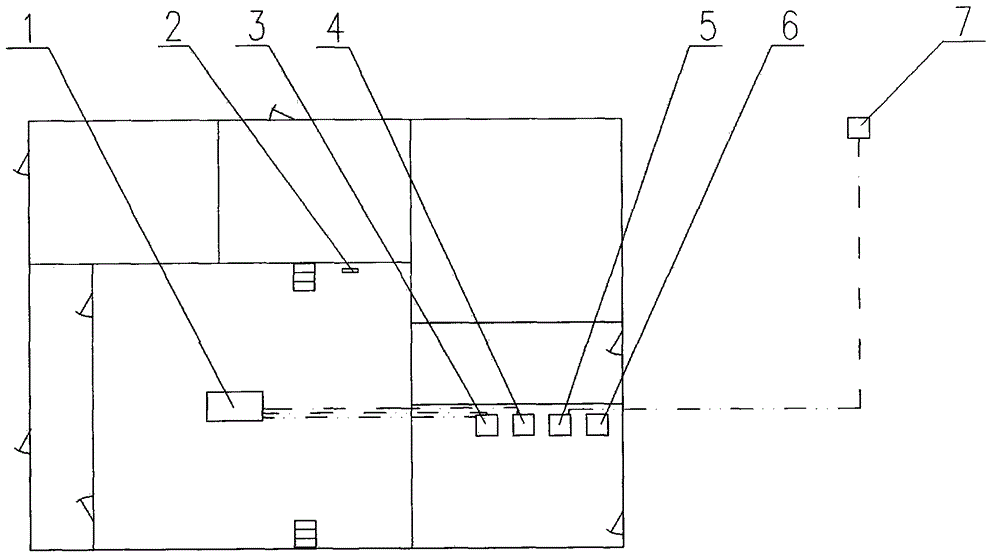

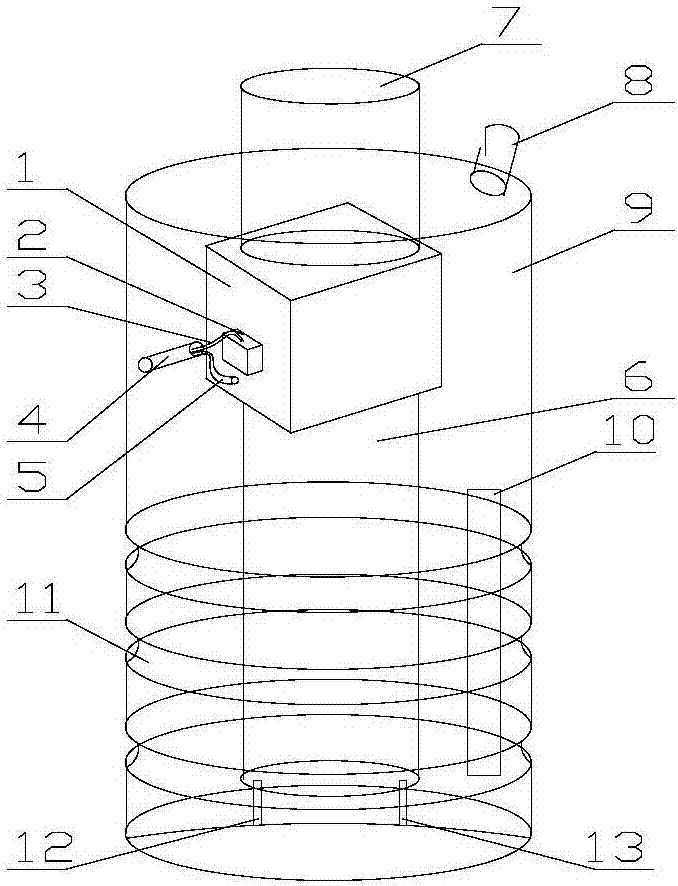

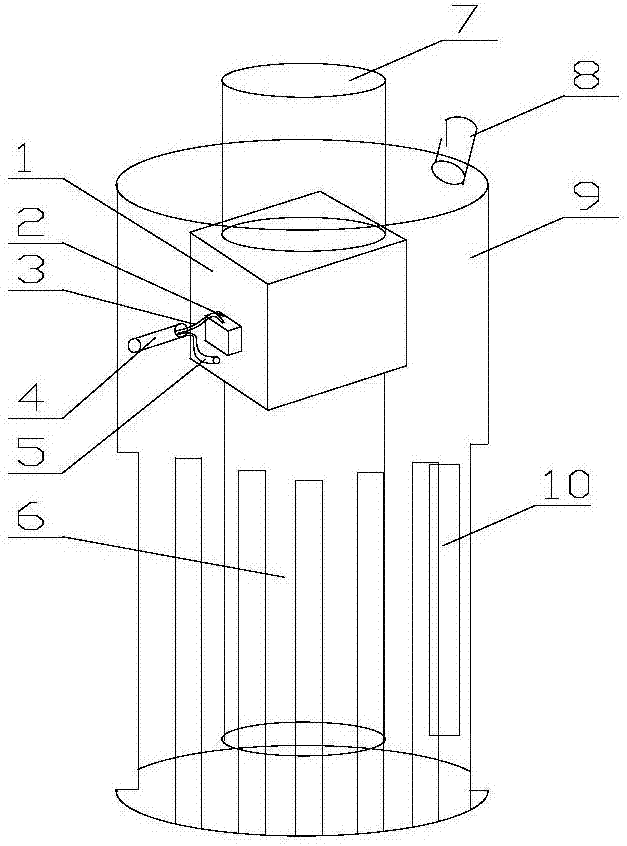

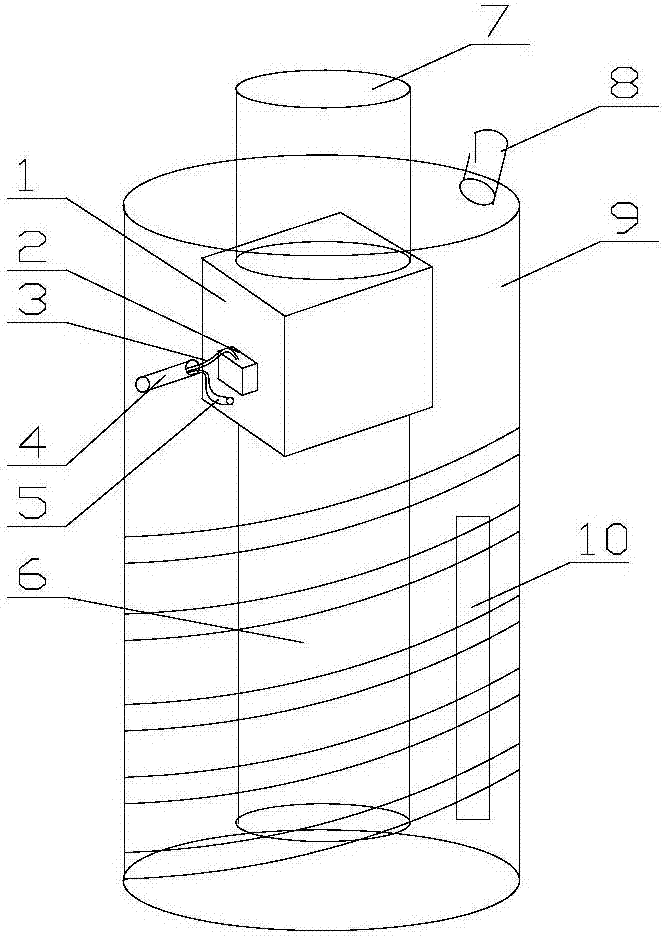

Fire source and smoke simulation training system

InactiveCN104464426AShort ignition timeEasy to useCosmonautic condition simulationsSimulatorsCombustionEconomic benefits

The invention relates to a fire source and smoke simulation training system. The fire source and smoke simulation training system includes a fire pool (1), an electric fire simulator (2), a fuel oil storage and transportation cabinet (3), a pneumatic part (4), a system control cabinet (5), a first smoke generator (6) and a remote controller (7), wherein the fire pool (1) and the electrical fire simulator (2) are installed in a simulation cabin, and the fuel oil storage and transportation cabinet (3), the pneumatic part (4), the system control cabinet (5) and the first smoke generator (6) are installed at the exterior of the simulation cabin. With the fire source and smoke simulation training system of the invention adopted, a fire source and smoke in a fire can be simulated. The fire source and smoke simulation training system is simple and convenient to use. According to the fire source and smoke simulation training system of the invention, the ignition time of the fire pool is short, and the fire pool can be refueled repeatedly; and a combustion area can be increased or decreased according to actual needs; a plurality of safety measures are adopted, so that high safety can be realized; and the fire source and smoke simulation training system can be trained and used repeatedly, so that the cost and use cost of the device are low, and therefore, great economic benefits can be brought about.

Owner:中国人民解放军92537部队 +1

Preparation method of environmentally-friendly bio-combustible granular fuel

InactiveCN108624374AShort ignition timeHigh calorific valueBiofuelsSolid fuelsEnvironmental resistanceEngineering

The invention discloses a preparation method of environmentally-friendly bio-combustible granular fuel. The preparation method is a process method for making the bio-granular fuel by adopting crop straws and forest wastes as raw materials and comprises the following specific steps: (1) preparation; (2) drying; (3) pressure-forming; (4) packaging. Compared with other fuel preparation processes, thepreparation method disclosed by the invention has the benefits that the production cost is low, the preparation process is simple, the prepared bio-granular fuel is short in ignition time, high in calorific value, long in burning time, and full and complete in combustion and not only eliminates various potential safety hazards brought by incinerating the straws by people, but also reduces the possibility of environmental pollution.

Owner:刘冬良

Biomass particle fuel

InactiveCN106147915AImprove drynessHigh densityBiofuelsSolid fuelsLivestock manureNon-renewable resource

The invention discloses a biomass particle fuel. The biomass particle fuel is prepared from 10%-20% of bamboos, 50%-60% of xylon, 2%-6% of rice hull, 10%-15% of livestock manure, 8%-12% of grease, 6%-10% of coal gangue powder and 0.5-1% of calcium oxide. According to the biomass particle fuel, the bamboos, various kinds of xylon, the rice hull, the livestock manure, the waste grease, the coal gangue powder and calcium oxide are combined, the raw material source is wide, waste biomass is fully utilized, energy saving and environment friendliness are achieved, the heating value is large, non-renewable energy resources can be fully utilized, and emissions of carbon dioxide, sulfur dioxide and other harmful gas can be reduced. Meanwhile, the biomass particle fuel can fundamentally solve the problem that the utilization rate of rural waste is low, waste is turned into wealth, and environment friendliness and energy saving are achieved.

Owner:长沙振科新能源科技有限责任公司

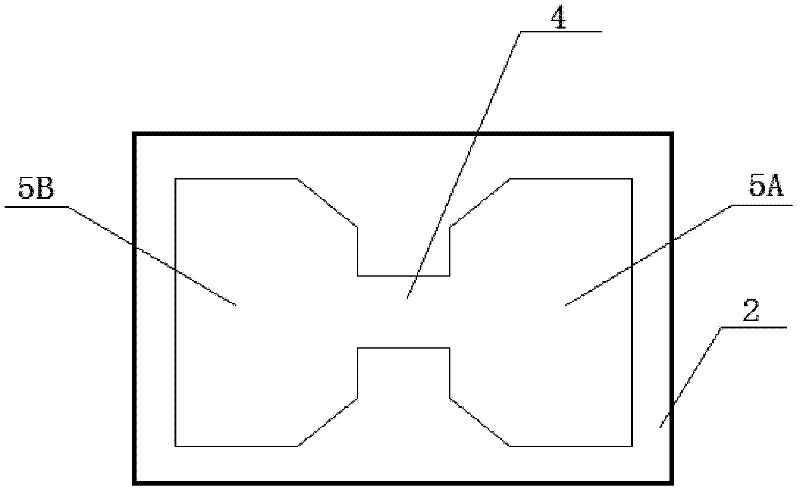

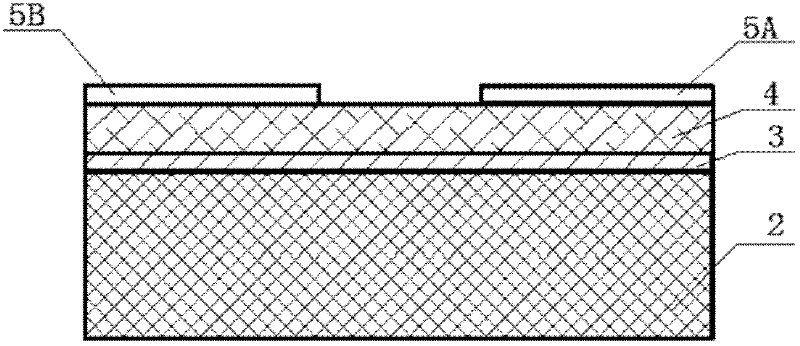

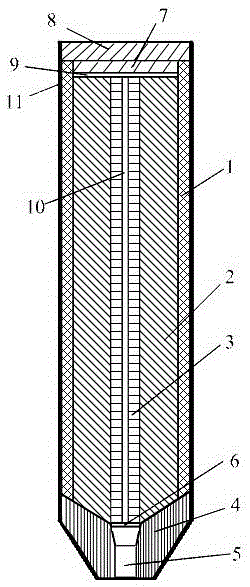

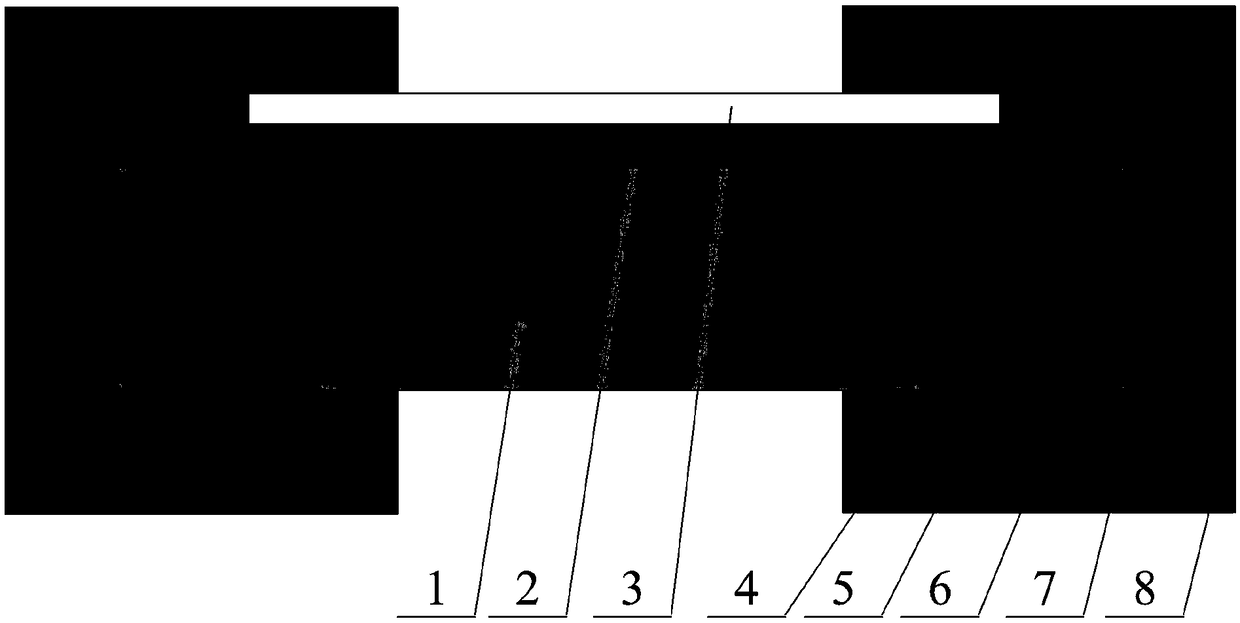

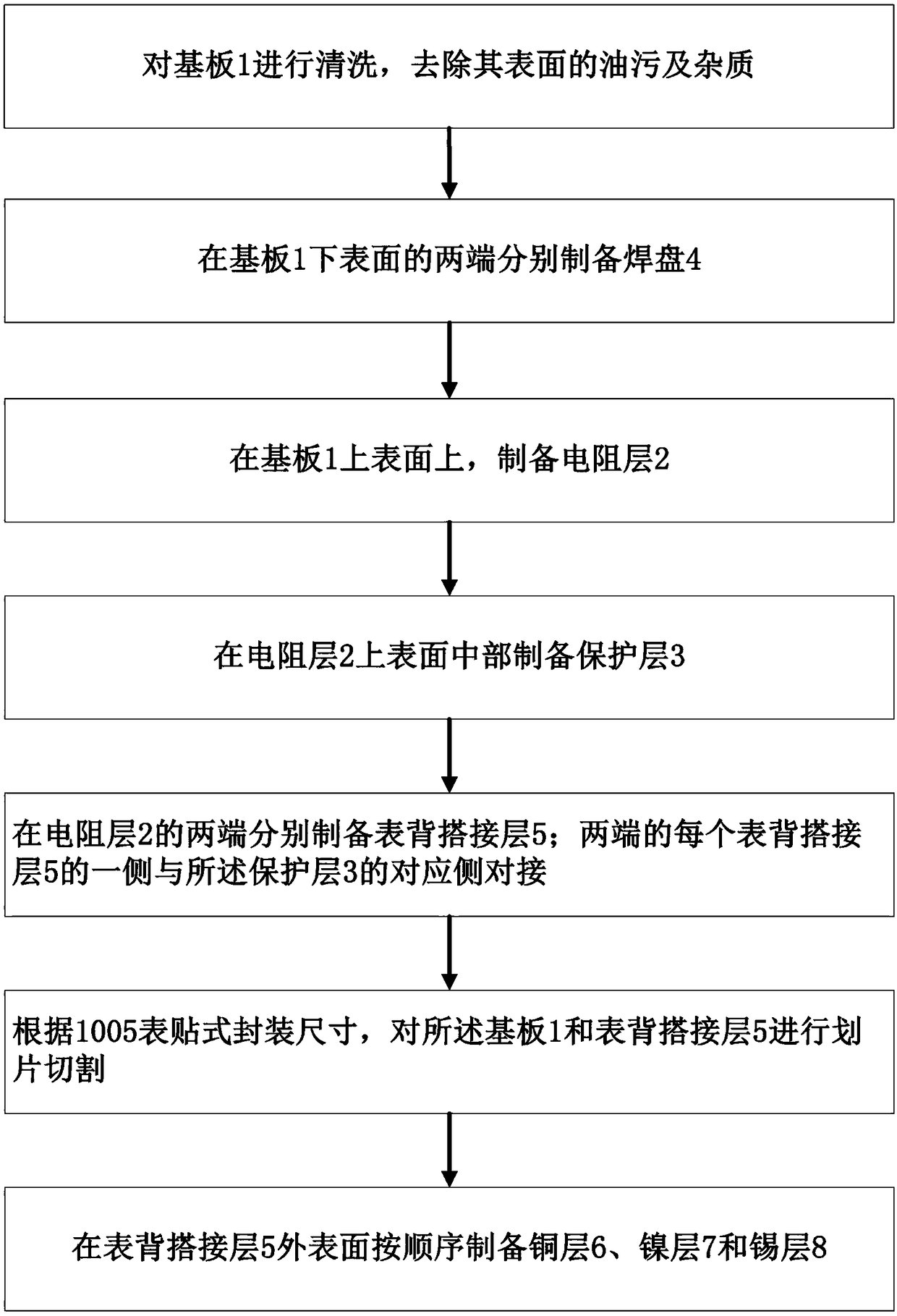

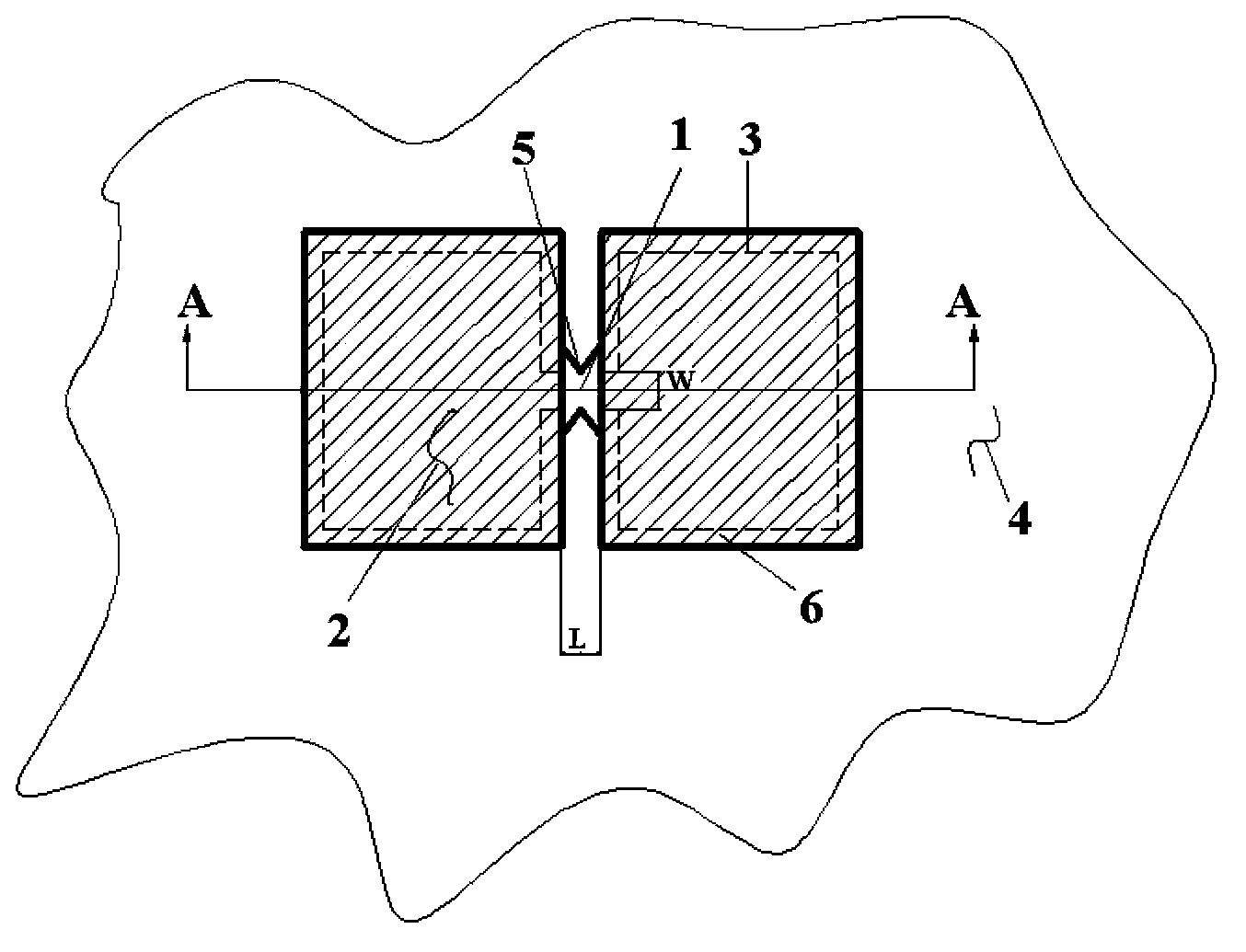

Miniature surface-mounted ignition resistor and preparation method thereof

ActiveCN108981506AReduce package sizeIncrease the areaAmmunition fuzesElectrical resistance and conductancePower flow

The invention relates to a miniature surface-mounted ignition resistor and a preparation method thereof, belongs to the technical field of electric explosive devices, and solves the problems of oversize encapsulation dimension, relative too high firing current and poor safety in the prior art. The miniature surface-mounted ignition resistor disclosed by the invention comprises a base plate 1, a resistance layer 2, a protection layer 3, bonding pads 4, a surface back lap joint layer 5, a copper layer 6, a nickel layer 7 and a tin layer 8, wherein the resistance layer 2 is arranged on the uppersurface of the base plate 1; the bonding pads 4 are respectively arranged at two ends of the lower surface of the base plate 1; the two ends of the resistance layer 2 are connected with the corresponding bonding pads 4 through the surface back lap joint layer 5; the protection layer 3 is also arranged on the middle part of the upper surface of the resistance layer 2; the copper layer 6, the nickellayer 7 and the tin layer 8 are sequentially arranged at the outer surface of the surface back lap joint layer 5. The ignition resistor has the advantages that the encapsulation dimension is small; the ignition current is about 0.1A; the ignition time is smaller than 100mus; the firing energy is about 1mJ; the fast firing under the micro excitation can be realized; the safety performance is good;the prominent technical advantages are realized.

Owner:BEIJING MECHANICAL EQUIP INST

Anti-slagging biomass pellet fuel and preparation method thereof

InactiveCN113322111AImprove molding rateHelp shapeBiofuelsSolid fuelsHydroxypropylmethyl celluloseEnvironmental chemistry

The invention relates to the field of fuels, in particular to an anti-slagging biomass pellet fuel and a preparation method thereof. The anti-slagging biomass pellet fuel is prepared from straw, peanut shells, sawdust, activated sludge, fly ash, mushroom stick waste residues, dealkalization treatment liquid, hydroxypropyl methyl cellulose, modified kaolin and an anti-slagging agent. The biomass pellet fuel prepared by the invention is low in slagging rate (less than or equal to 0.12%), high in calorific value (greater than or equal to 2.42 MJ / kg), short in ignition time (less than or equal to 50s), high in crushing strength and not easy to crack and generate dust in the storage and transportation processes, and is a relatively ideal fuel capable of replacing coal.

Owner:湖南创威科技有限公司

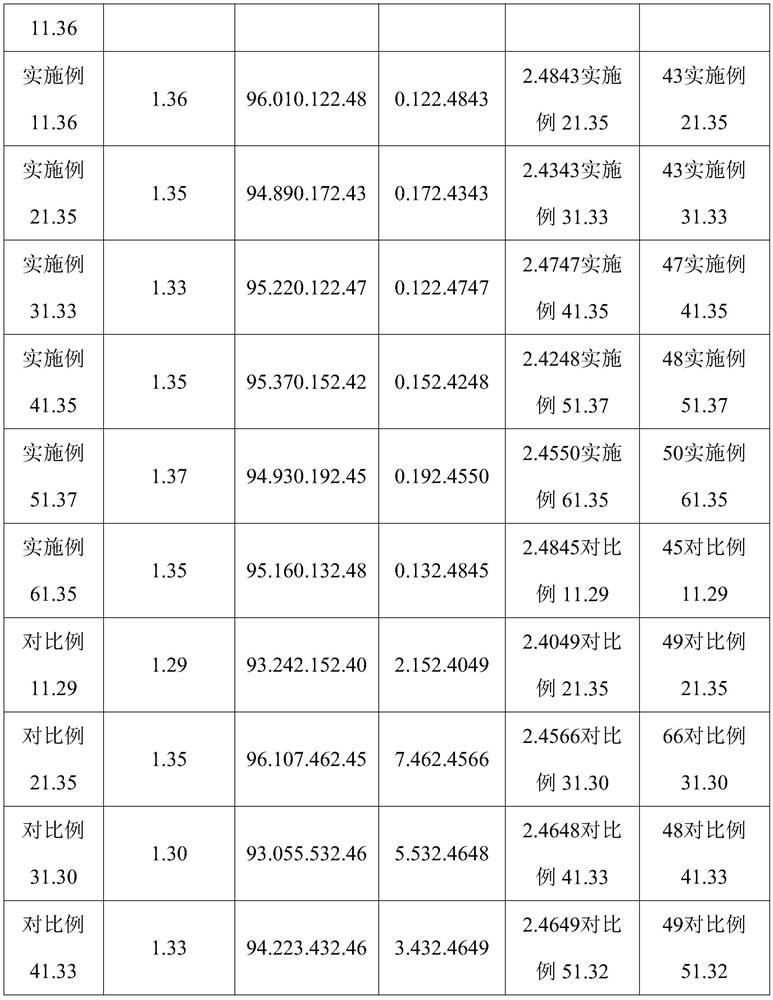

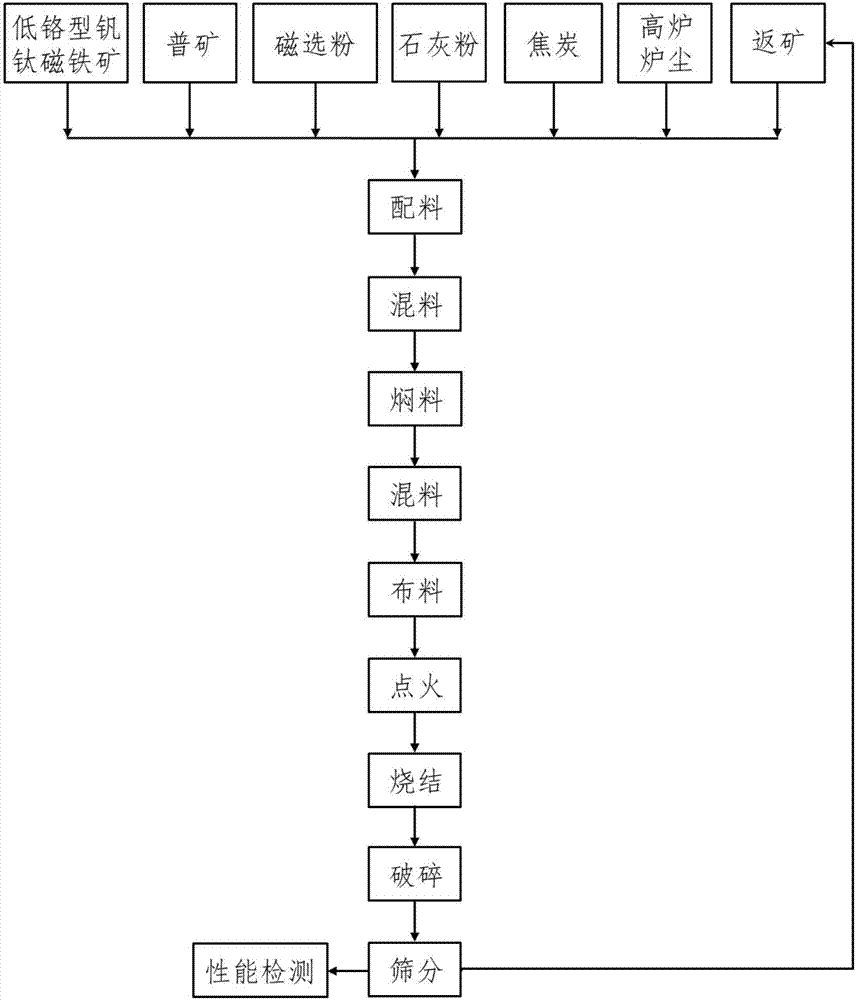

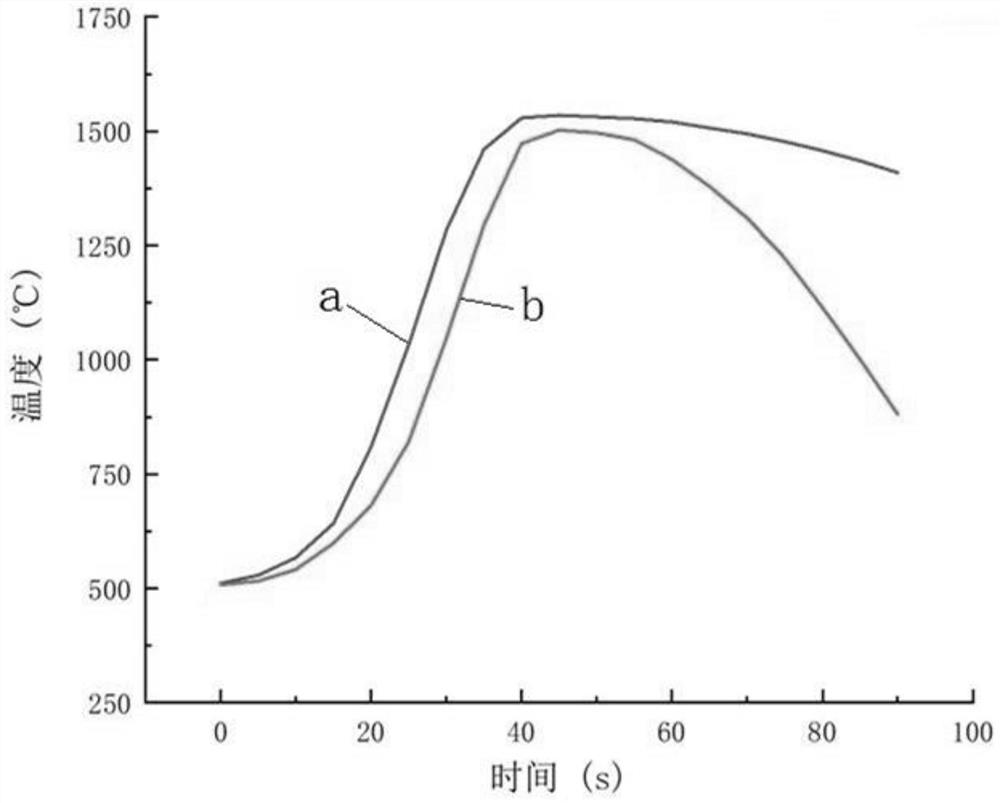

Method for preparing sintered ores by adding common iron ores into low-chromium vanadium titano-magnetite

The invention discloses a method for preparing sintered ores by adding common iron ores into low-chromium vanadium titano-magnetite. The method is characterized in that the low-chromium vanadium titano-magnetite, the common iron ores and other sintered materials are subjected to the following steps of material mixing, material stewing, material mixing, material pelleting, material distribution, ignition, sintering, crushing and sieving to obtain the sintered ores. According to the method, the obtained low-chromium vanadium-titanium sintered ores has the advantages that the sintering rate is high, the soft melting temperature is high, the soft melting interval is narrow, the obtained sintered ores have good air permeability in a soft melting and dropping zone, and the performance of moltendrops is good.

Owner:NORTHEASTERN UNIV

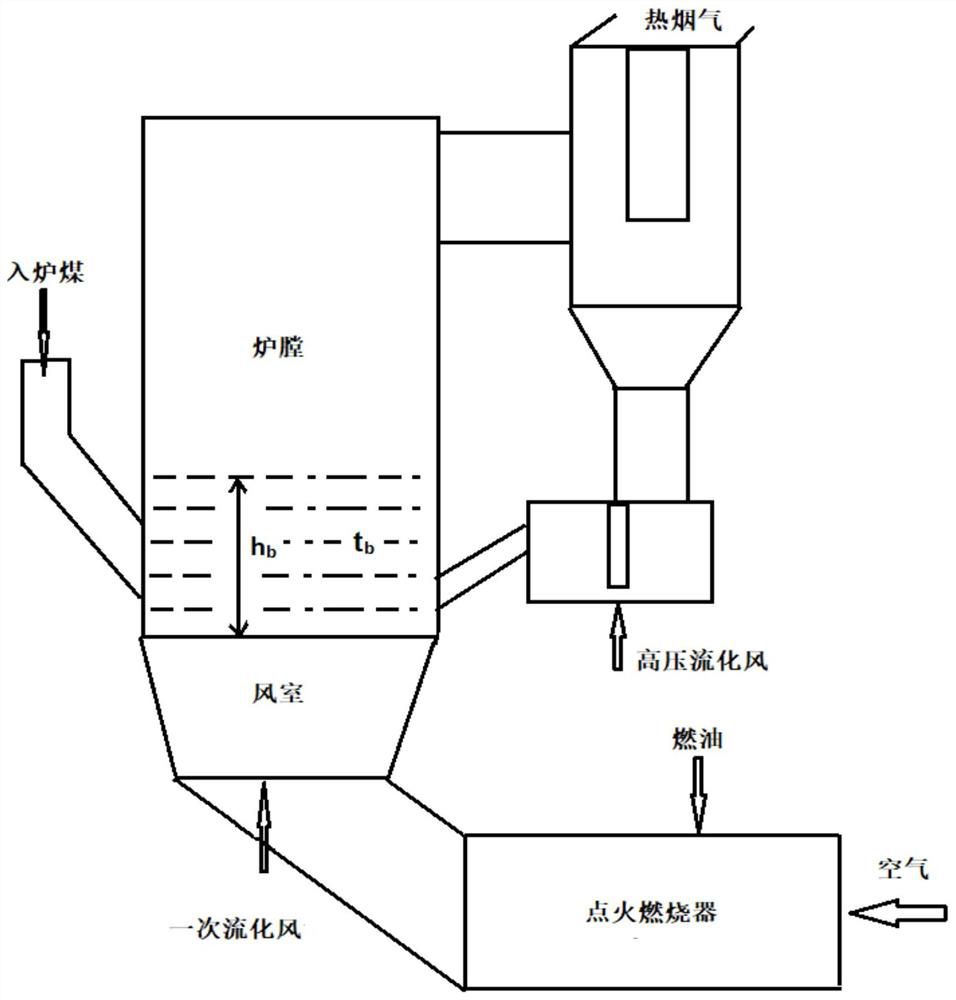

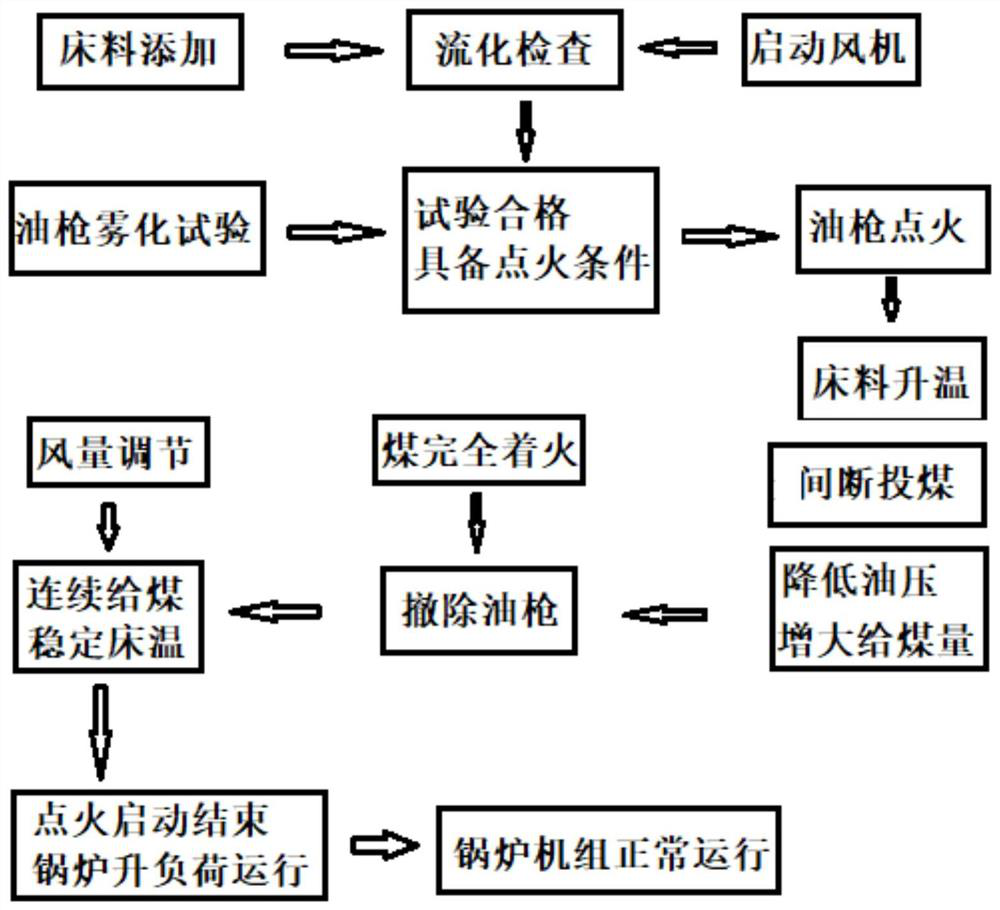

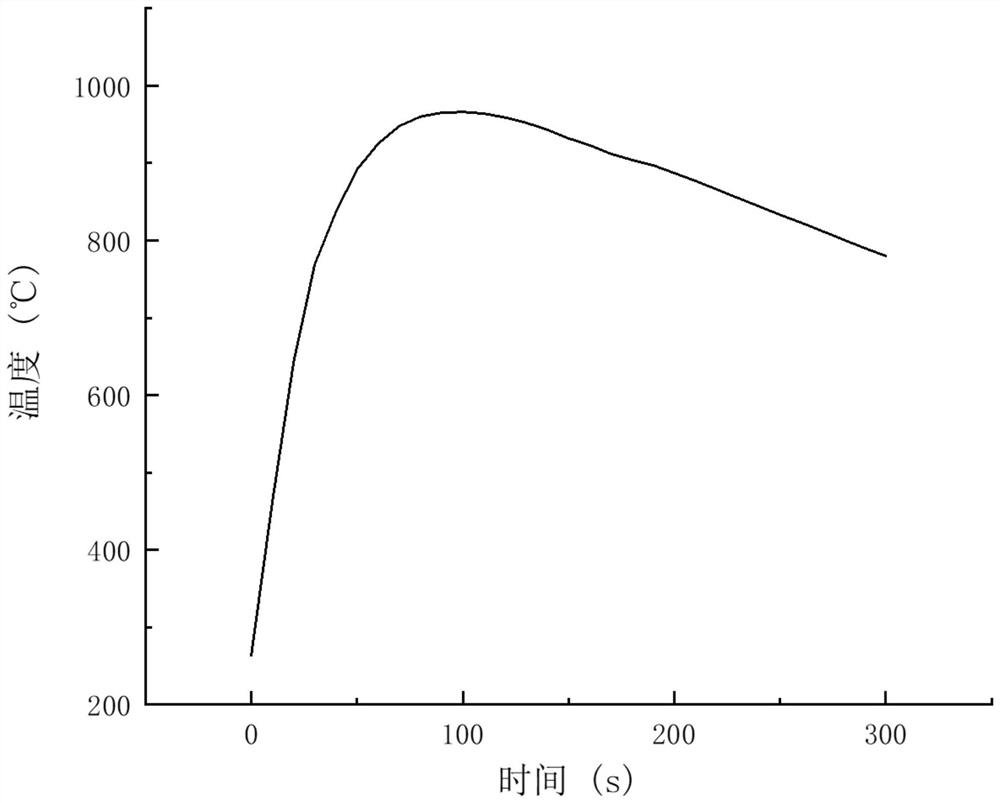

Microfluidization cold-state ignition starting method for circulating fluidized bed boiler

InactiveCN113028392AReduce oil pressureShort ignition timeFluidized bed combustionApparatus for fluidised bed combustionCombustorFluidized bed

The invention discloses a microfluidization cold-state ignition starting method for a circulating fluidized bed boiler, and belongs to the technical field of energy power. The starting method comprises the following steps: S1, testing whether an ignition condition is met or not, if yes, entering the next step, and if not, returning to debug; S2, igniting through an oil gun to heat a bed layer; S3, according to different initial coal feeding temperatures of ignition of different coal types, after the bed layer is heated to a preset temperature, starting intermittent coal feeding, wherein in the coal feeding process, the oil pressure of the oil gun is gradually reduced along with the increase of the coal feeding amount; and S4, when the temperature of the bed layer reaches 630-670 DEG C, starting to withdraw the oil gun, and when the temperature of the bed layer reaches 780-820 DEG C, removing the whole oil gun. Therefore, the problems of slow temperature rise of bed materials, large bed temperature deviation, long starting time, high oil consumption and the like can be well solved, operation accidents such as hearth coking and ignition burner damage are effectively avoided, and then the safety and economical efficiency of cold ignition starting of the circulating fluidized bed boiler are greatly improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

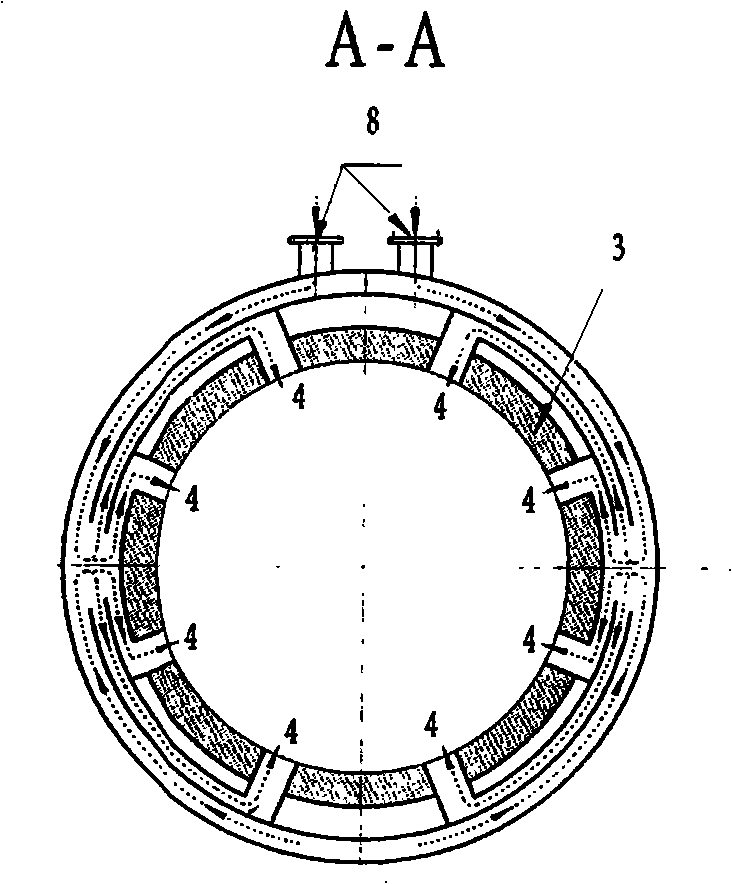

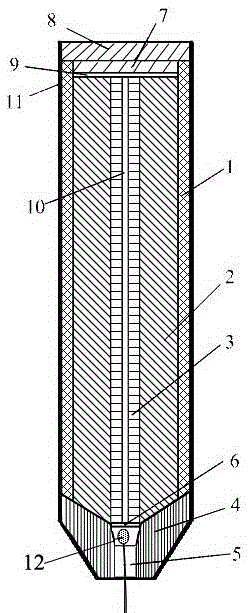

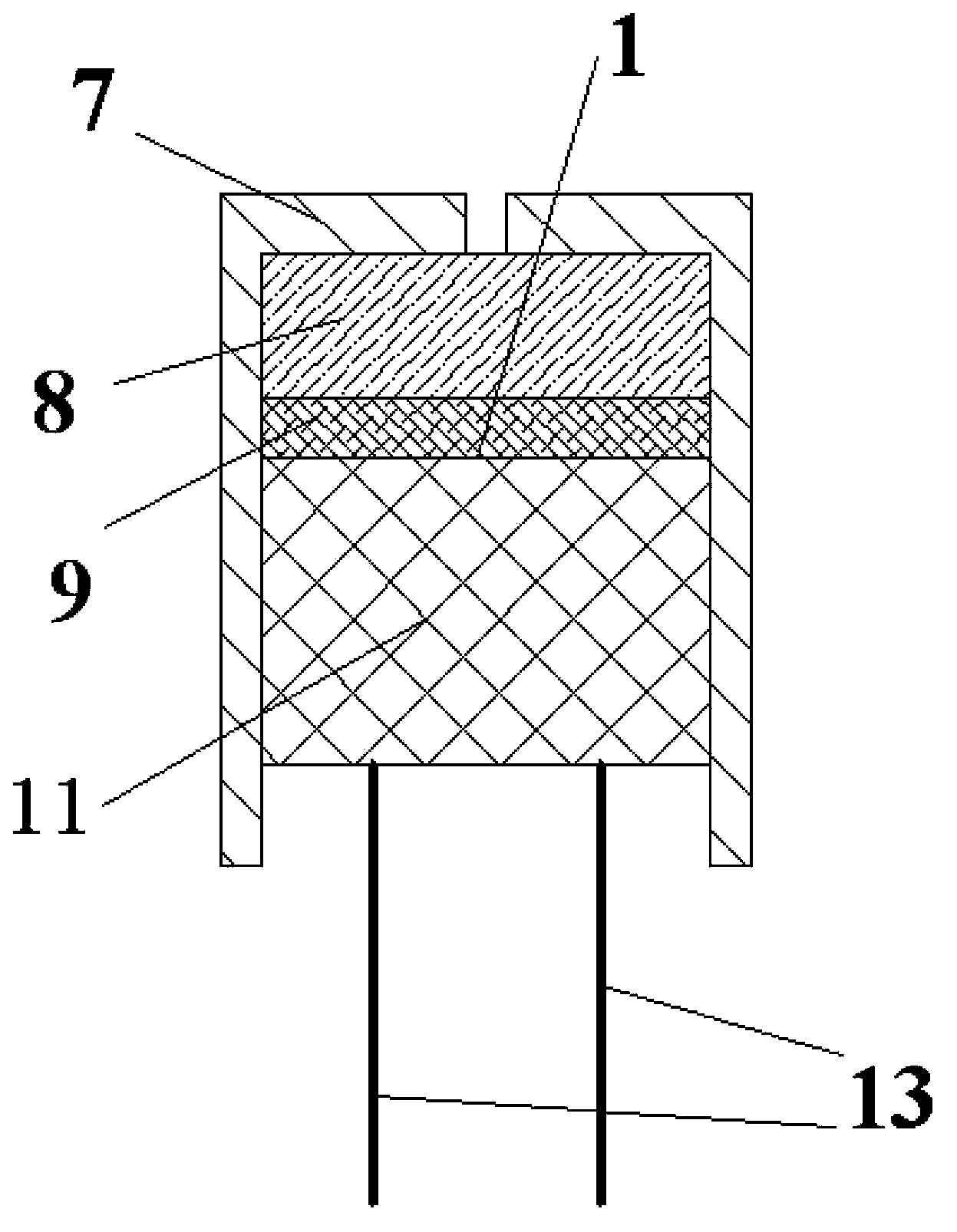

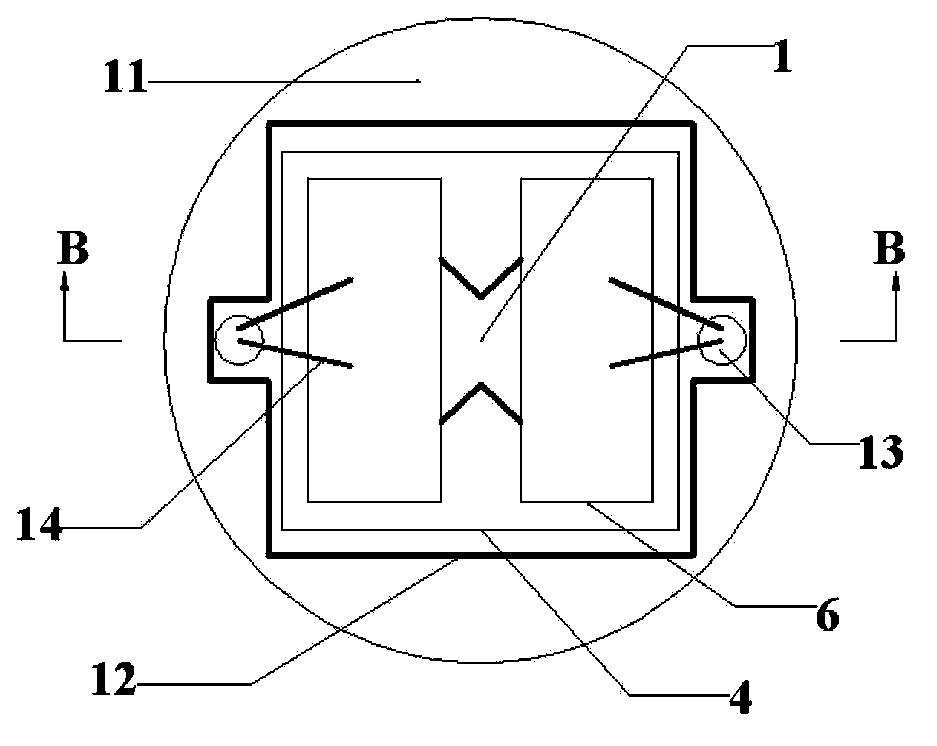

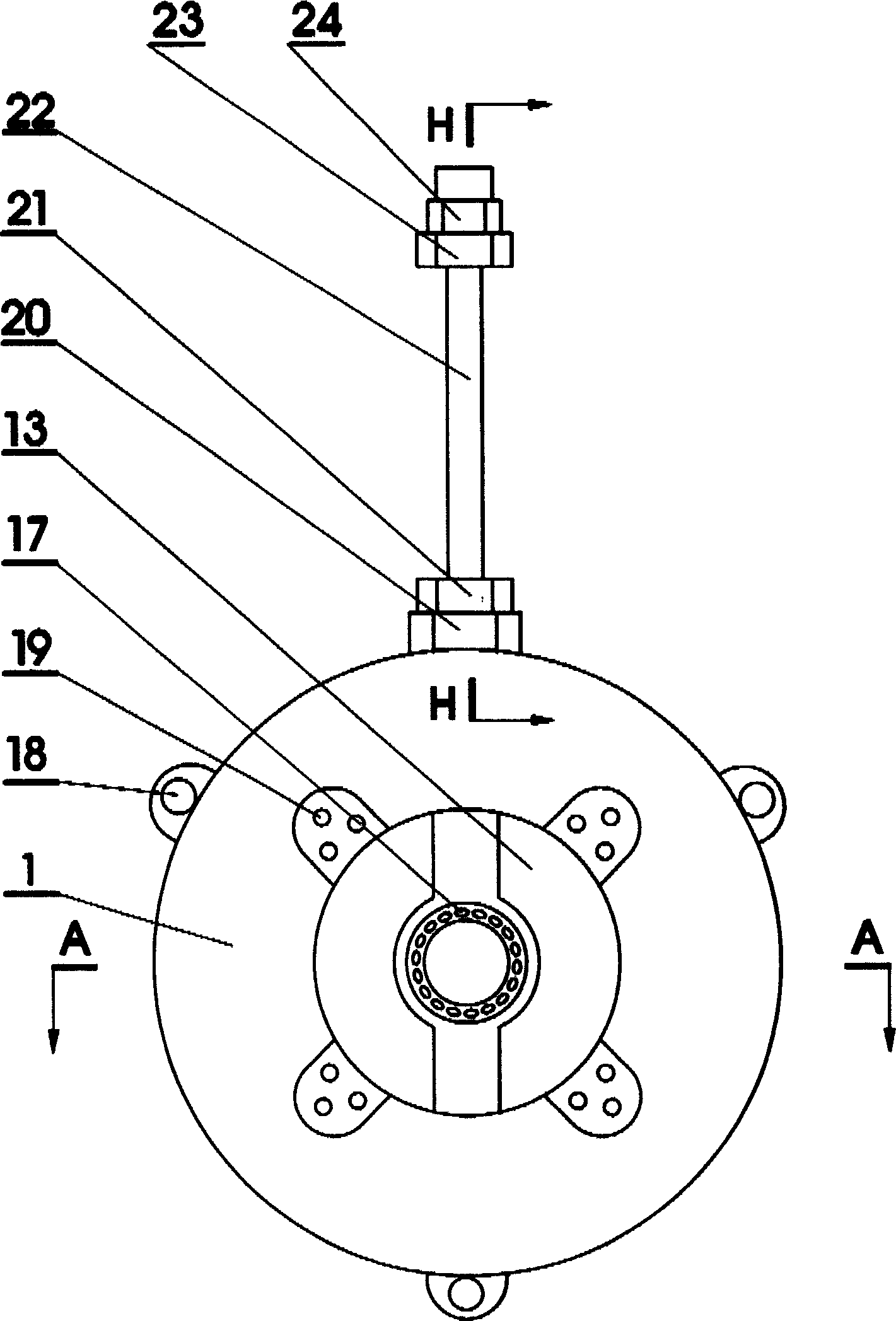

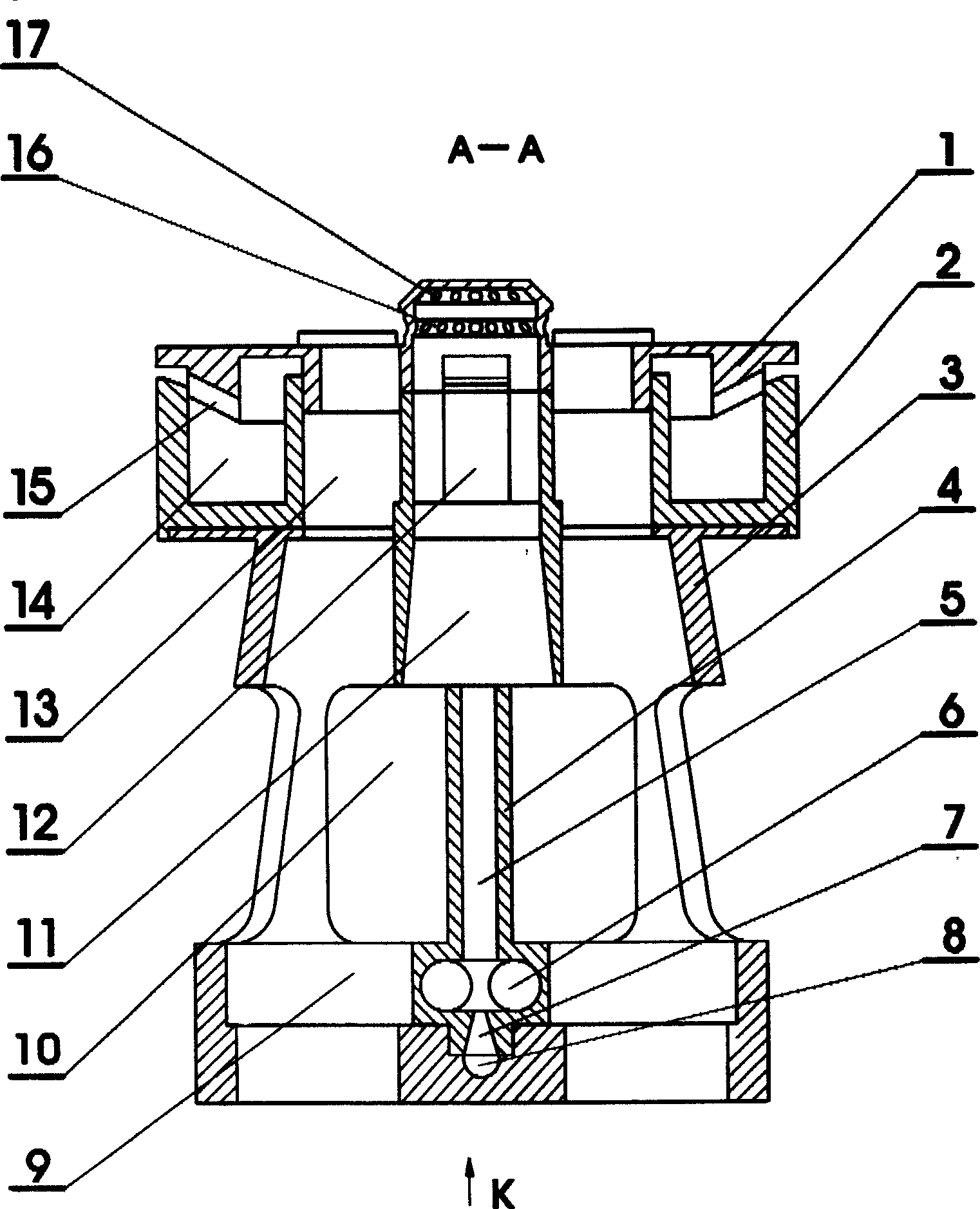

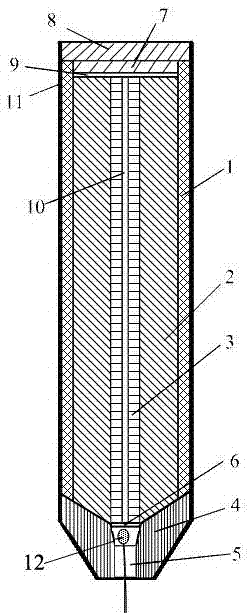

High-voltage instant semiconductor bridge ignition module

The invention provides a high-voltage instant semiconductor bridge ignition module, and belongs to the field of a semiconductor bridge ignition device. The high-voltage instant semiconductor bridge ignition module comprises a tube shell (7), and propellant and an energy replacing element which are arranged in the tube shell (7), wherein the tube shell (7) has a sleeve structure, one end of the tube shell (7) is an open end, and the other end of the tube shell (7) is a closed end; the closed end of the tube shell (7) is provided with an axial through hole; the energy replacing element comprises a ceramic electrode plug (11); a semiconductor bridge chip is arranged above the ceramic electrode plug (11); the semiconductor bridge chip sequentially comprises a silicon substrate, a polycrystalline silicon substrate (4), an electric bridge (1) and an aluminium electrode (6) from bottom to top; the lower end surface of the silicon substrate is bonded on the upper end surface of the ceramic electrode plug (11); the aluminium electrode (6) comprises two electrode areas (3) which are separated from each other and are symmetrically arranged; the two electrode areas (3) are connected with each other by the electric bridge (1).

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

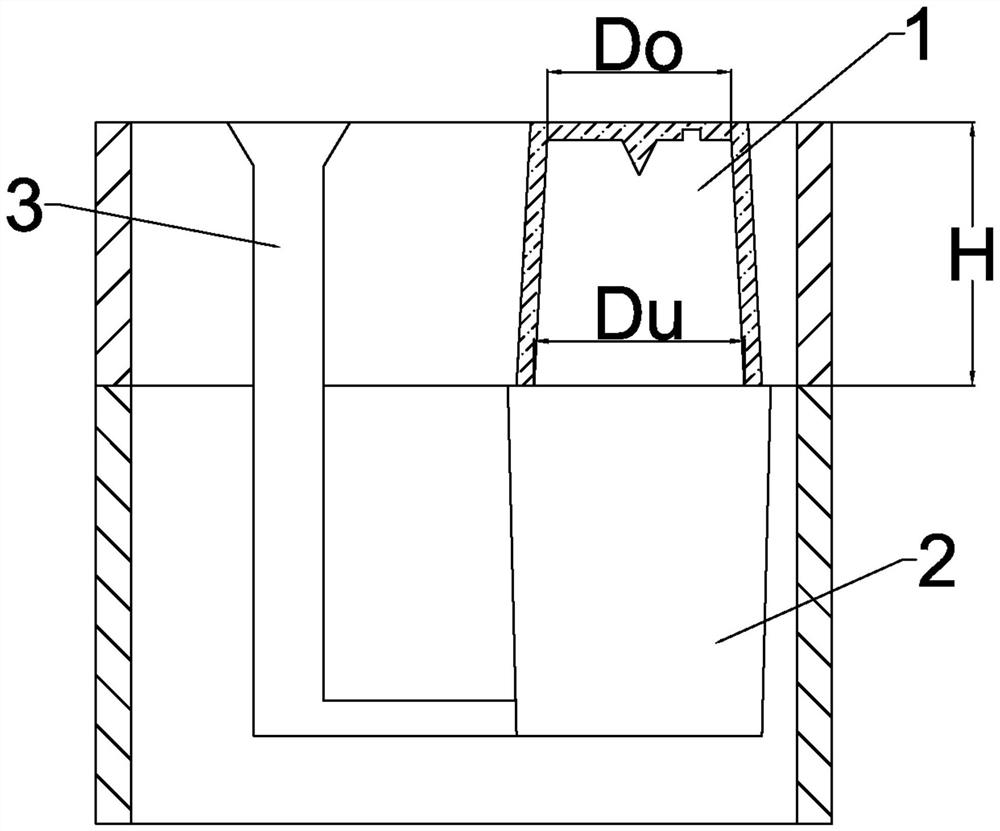

Organic silicon slag exothermic and insulating riser sleeve and preparation method thereof

The invention provides an organic silicon slag exothermic and insulating riser sleeve and a preparation method thereof. The insulating riser sleeve comprises the following raw materials of organic silicon slag, an oxidizing agent, refractory aggregate, an ignition material, a fluxing agent and a binder. According to the organic silicon slag exothermic and insulating riser sleeve, the organic silicon slag is used as a heating agent to partially or completely replace aluminum powder and aluminum slag, so that the riser sleeve has the advantages of energy conservation and emission reduction, low cost, low ignition temperature, short ignition time, excellent heating stability, no deflagration, long heat-insulating time, easiness in storage and the like; the problems of high cost, short storage period, deflagration and the like of the existing exothermic and insulating riser are solved; and during casting, under the combined action of heating and long heat preservation, the temperature of molten metal in the riser is increased through released heat, the solidification time of the molten metal in the riser is prolonged, the feeding time is prolonged, and the metal feeding rate in the riser is greatly increased.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Explosive composition and preparation method thereof

InactiveCN109369311AProportion design is reasonableIncrease the calorific value of combustionExplosive working-up apparatusChemical industrySolid fuel

The invention discloses an explosive composition and a preparation method thereof and belongs to the field of chemical industry. The explosive composition disclosed by the invention comprises: fuel oil, a throwing agent, ammonium nitrate particles, a cracking agent, an expanding agent and an electrolyte solution; the explosive composition comprises the raw materials in parts by weight: 10 to 20 parts of the fuel oil, 20 to 40 parts of the throwing agent, 20 to 30 parts of the ammonium nitrate particles, 10 to 30 parts of the cracking agent, 20 to 30 parts of the expanding agent and 50 to 70 parts of the electrolyte solution; the explosive composition disclosed by the invention adopts a reasonable proportion design; a combustible agent is selected from a mixture composed of wood charcoal, aluminum powder and magnesium powder; compared with a wood charcoal combustible agent, the aluminum powder and the magnesium powder have high combustion calorific value; compared with an explosive composition in the prior art, the explosive composition generates a relatively great impact wave component force in an explosion process; the explosion strength is ideal, and the explosion performance ofexplosive and solid fuel is stable; and the explosive composition and the preparation method thereof are worthy of being popularized and applied.

Owner:杜洪波

Energy-saving cooker with complete gas fuel combustion and digital display controlling function

InactiveCN1584406AShort ignition timeDigital display timingDomestic stoves or rangesGaseous fuel burnerEngineeringControl circuit

An energy-saving stove with digital display consists of one, at least, burner installed on supporting rack in its chamber, and a display panel installed on the outer surface of the stove and connected with a digital controlling-circuit. Its advantages include combustion efficiency at 99.8%, quick starting, reliable digital display, and convenient in use.

Owner:胡汉全

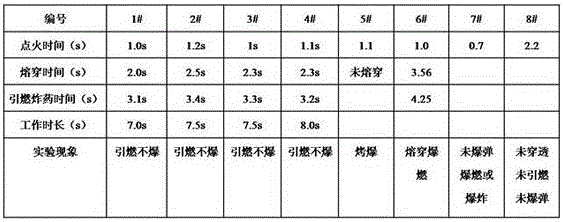

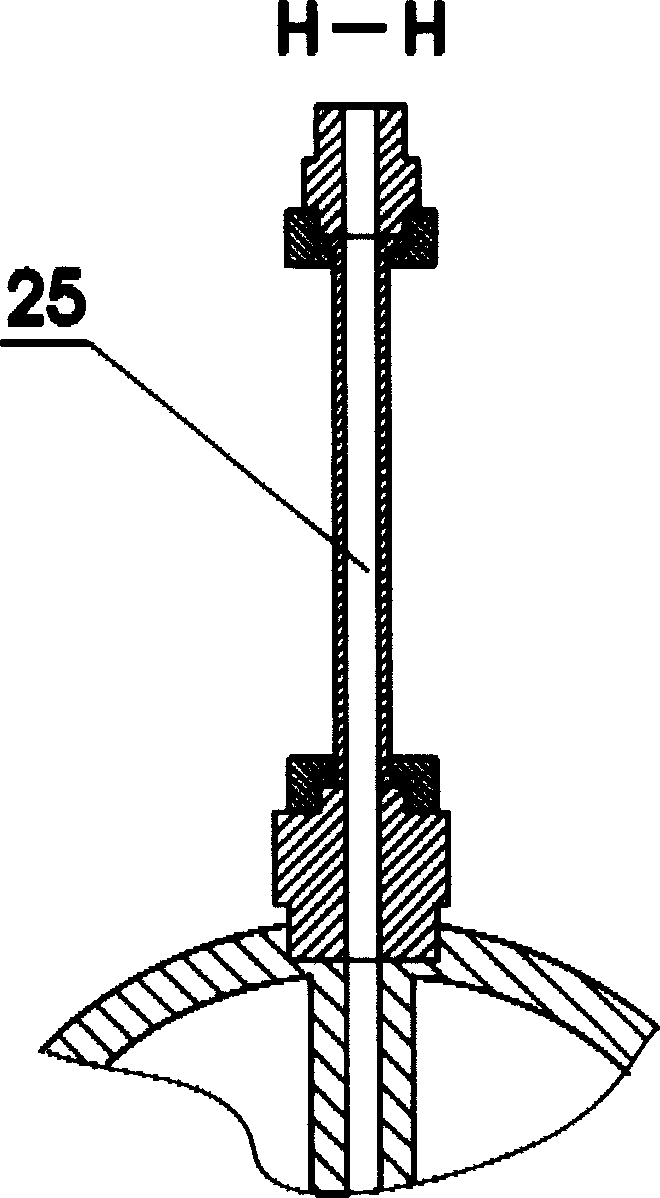

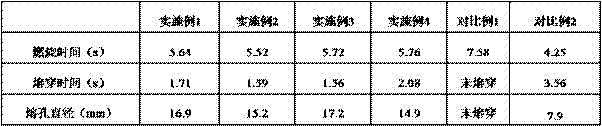

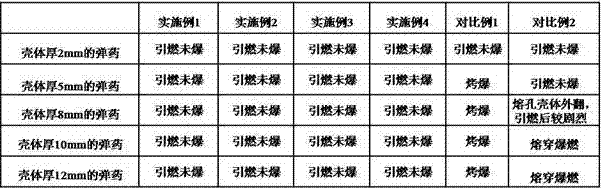

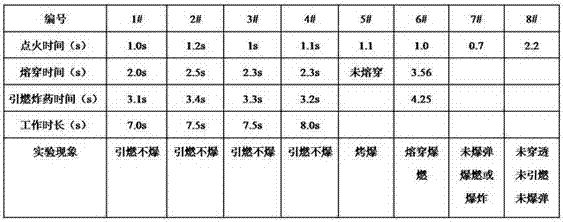

A kind of composite incendiary agent for destroying bombs and its preparation method

InactiveCN105732241BImprove ignition abilityShort ignition timeBlastingExplosivesSesquioxideCopper oxide

The invention provides a composite incendiary agent for destroying ammunitions and a preparation method of the composite incendiary agent. The composite incendiary agent is prepared from the following components in percentage by weight: 60%-70% of a main reaction medicament, 1%-5% of a diluent, 5%-10% of a gas making agent and 20%-30% of an auxiliary medicament, wherein the main reaction medicament is prepared from 0.3-1.5 parts of iron sesquioxide, 1.6-2.9 parts of ferroferric oxide and 1 part of powdered aluminum; the dilute is alumina powder; the gas making agent is prepared from 0-5 parts of silicon carbide powder and 6 parts of potassium nitrate powder; the auxiliary medicament is prepared from 6 parts of copper oxide powder, 4 parts of powdered aluminum, 1-3 parts of silicon dioxide powder, 5 parts of nickel powder, 0-3 parts of calcium fluoride powder and 0-3 parts of calcium carbonate powder. The composite incendiary agent is stable, the combustion pressure is uniform, the fluidity of generated metal melt is good, the jet velocity meets incendiary requirements of the ammunitions, and the composite incendiary has strong capacity for smelting shells of projectiles the strong capacity for igniting explosives and does not detonate the explosives. When applied to the destroying of the ammunitions, the composite incendiary agent is low in dosage, high in action speed, relatively safe, efficient and convenient.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

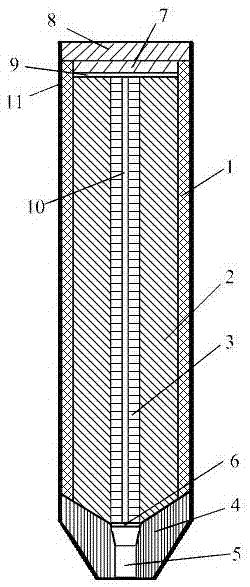

Deflagration bomb and preparation method thereof

InactiveCN105674828BReasonable structural designImprove acceleration performanceBlasting cartridgesBlastingEngineeringFrustum

The invention provides an ignition destroy bomb and a preparation method thereof. The ignition destroy bomb comprises an outer shell body, a jet nozzle, a tubular powder column and a seal cap, wherein the jet nozzle, the tubular powder column and the seal cap are sequentially arranged inside the outer shell body from bottom to top. The outer shell body includes an upper cylindrical portion and a lower conical frustum portion. The jet nozzle is arranged inside the conical frustum portion of the outer shell body. Furthermore, the external surface of the jet nozzle abuts against the internal wall of the conical frustum portion. A cylinder-shaped inner shell body is arranged inside the cylindrical portion of the outer shell body and abuts against the internal wall of the cylindrical portion. The powder column is loaded inside the inner shell body. The powder column includes a main powder charging column and an igniting powder column, wherein the bottom end face of the main powder charging column is a conical surface protruding outwards, and the conical surface is attached to the top portion of the jet nozzle closely; the igniting powder column is loaded in an inner cavity of the main powder charging column, and the length of the igniting powder column is equal to that of the main powder charging column; and two pieces of seal paper are stick on the upper end face of the main powder charging column and the lower end face of the igniting powder column respectively. By means of the ignition destroy bomb, unexploded bombs can be destroyed fast, safely and efficiently.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Ignition device for biomass gasification furnace and using method thereof

InactiveCN101726002BPromote combustionImprove ignition success rateIncandescent ignitionCombustible gas productionElectricityEngineering

Owner:JIANGSU UNIV +1

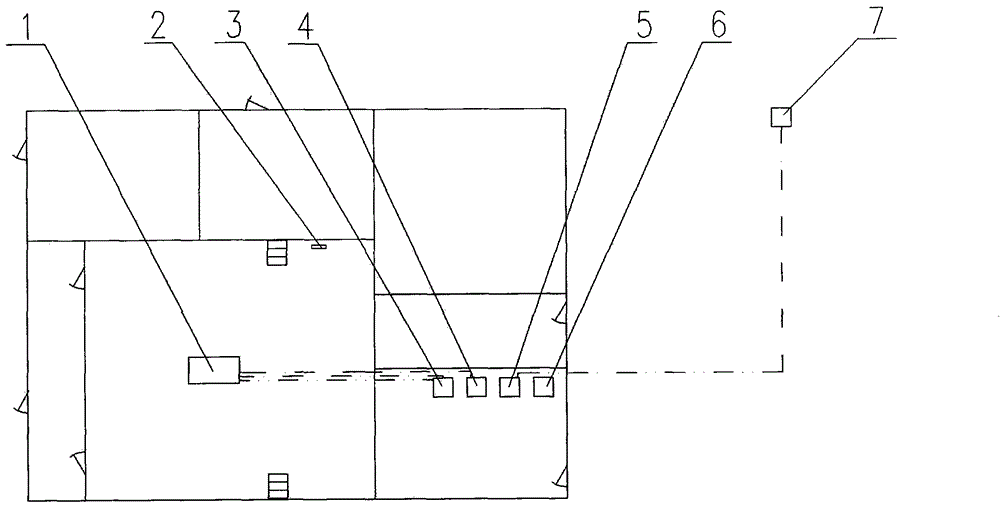

A belt type sintering machine ignition device

ActiveCN105042635BImprove ignition effectReduce consumptionCombustion ignitionCombustion chamberFuel distribution

The invention discloses an ignition device for a belt type sintering machine. The ignition device includes a fuel distribution chamber, the feed port of which communicates with the fuel inlet, and the discharge end of the fuel distribution chamber communicates with the inner cavity of the combustion chamber; the primary air distribution chamber, whose intake end communicates with the primary air inlet, the The outlet end of the primary air distribution chamber communicates with the inner chamber of the combustion chamber; the inlet end of the secondary air distribution chamber communicates with the secondary air inlet, and the outlet end of the secondary air distribution chamber communicates with the inner chamber of the combustion chamber; The outlet end of the fuel injection branch pipe merges with the outlet end of the primary air injection branch pipe, and after the air in the secondary air injection channel is ejected, it merges with the beam flame formed by the fuel combustion in the fuel injection branch pipe and enters the combustion chamber. The cavities meet to form a ribbon flame. The invention realizes strip ignition, short ignition time and less fuel consumption.

Owner:华楚智能科技(湖南)有限公司

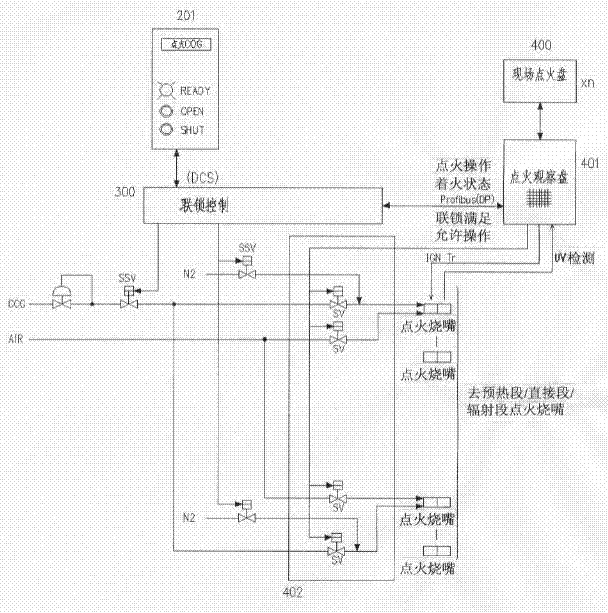

Ignition control system of cold-rolling continuous annealing furnace

ActiveCN102191369BReduce in quantityReduce engineering costsFurnace typesHeat treatment furnacesSolenoid valveIgnition coil

The invention relates to an ignition control system of a cold-rolling continuous annealing furnace. An ignition station is connected with a main control programmable logic controller and an ignition observing disc respectively; the main control programmable logic controller is bi-directionally connected with a field operation box; the ignition observing disc is bi-directionally connected with a field ignition disc; after being connected in parallel with a nitrogen pipe, a gas pipe is connected with an ignition nozzle; an air pipe is connected with the ignition nozzle; a pneumatic shutoff valve and a valve station are arranged on the gas pipe; the pneumatic shutoff valve is arranged on the nitrogen pipe; the valve station is arranged on the air pipe; the main control programmable logic controller is respectively connected with and controls the pneumatic shutoff valve; the ignition observing disc is connected with and controls the valve station; the main centre of the ignition observingdisc is the ignition observing disc consisting of a flame detection unit and a programmable logic controller (PLC) control unit; and ultraviolet flame detectors are uniformly arranged on the ignitionnozzle and are connected with the ignition observing disc. The system has few solenoid valves, low engineering cost, low maintenance cost, short ignition time, low debugging workload, high safety anda relatively independent ignition system.

Owner:BAOSTEEL ENG & TECH GRP

A fire source and smoke simulation training system

InactiveCN104464426BShort ignition timeEasy to useCosmonautic condition simulationsSimulatorsCombustionEconomic benefits

The invention relates to a fire source and smoke simulation training system. The fire source and smoke simulation training system includes a fire pool (1), an electric fire simulator (2), a fuel oil storage and transportation cabinet (3), a pneumatic part (4), a system control cabinet (5), a first smoke generator (6) and a remote controller (7), wherein the fire pool (1) and the electrical fire simulator (2) are installed in a simulation cabin, and the fuel oil storage and transportation cabinet (3), the pneumatic part (4), the system control cabinet (5) and the first smoke generator (6) are installed at the exterior of the simulation cabin. With the fire source and smoke simulation training system of the invention adopted, a fire source and smoke in a fire can be simulated. The fire source and smoke simulation training system is simple and convenient to use. According to the fire source and smoke simulation training system of the invention, the ignition time of the fire pool is short, and the fire pool can be refueled repeatedly; and a combustion area can be increased or decreased according to actual needs; a plurality of safety measures are adopted, so that high safety can be realized; and the fire source and smoke simulation training system can be trained and used repeatedly, so that the cost and use cost of the device are low, and therefore, great economic benefits can be brought about.

Owner:中国人民解放军92537部队 +1

Energy-saving range with complete gas fuel combustion and digital display controlling function

InactiveCN1256535CBurn fullyShort ignition timeDomestic stoves or rangesGaseous fuel burnerControl circuitFuel gas

An energy-saving stove with digital display consists of one, at least, burner installed on supporting rack in its chamber, and a display panel installed on the outer surface of the stove and connected with a digital controlling-circuit. Its advantages include combustion efficiency at 99.8%, quick starting, reliable digital display, and convenient in use.

Owner:胡汉全

Ignition apparatus of product line for sintering porcelain granule

InactiveCN101269949BHigh efficiency of surface ignitionImprove ignition efficiencyClaywaresProduction lineThermal energy

The present invention relates to an ignition method and an ignition device, which are applied to the baking porcelain grain production line. The ignition method: the temperature of the ignition device is increased to pre-determined temperature, generally 800 to 1350 DEG C, a baking box that is fully provided with the baking raw materials is close to the ignition device at high temperature to reach the closed state, and then to be preheated; the baking box is ventilated with air or other combustion-assistant gas to assist the combustion, so that the surface of the raw materials can be combusted adequately; the temperature in the ignition device is introduced downwards by the guiding air so as to increase the thickness of the ignition layer; the air introduction is stopped after the ignition, and the ignited baking box is moved to a next position, and simultaneously the next baking box that is fully provided with the baked raw materials is moved to the ignition position. With the present invention, the ignition efficiency at the surface of the baking box is high, thereby greatly reducing the heat waste and shortening the ignition time; moreover, the porcelain grain that is arranged on the surface of the baking box is combusted adequately without breaking or dust; the particle is complete, thus improving the rate of the finished product of the production line. The ignition devicehas simple structure, not only has low production cost, but also greatly reduces the running operation compared with the traditional ignition system.

Owner:BEIJING SIDIQI SCI & TECH

Anti-scald cigarette lighter

The invention discloses an anti-scald cigarette lighter, comprising an igniting mechanism, a connection device, an igniting wire, a flame outlet, a gas outgoing tube, a gas reservoir, a button, and a crystal shell; a cylinder is provided with an inner cavity along its axis, the upper end of the cavity of the cylinder is opened with the lower end not opened, the igniting mechanism is disposed in the upper middle of the cavity and completely divides the cavity into an upper part and a lower part, the lower cavity part of the igniting mechanism is provided with the gas reservoir, the upper cavity of the igniting mechanism is provided with the button, and the button is connected to the igniting mechanism; the part of the crystal shell at the same horizontal position as the igniting mechanism is provided with the flame outlet, the connection device, used for setting the igniting wire, on the igniting mechanism is arranged at an inner outlet of the flame outlet, and the igniting wire is arranged within the flame outlet; one end of the gas outgoing tube is connected to the igniting mechanism, and the other end of the gas outgoing tube is arranged within the flame outlet. The anti-scald cigarette lighter has the advantages that breaking resistance of the cigarette lighter is improved and burns due to heat transfer can be avoided.

Owner:宜宾晶之羽电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com