Ni-Cr alloy thin film igniter with low ignition voltage and preparation method thereof

An alloy thin film, low ignition technology, applied in the field of pyrotechnics, can solve the problems of reducing the reliability level of bridge wire igniters, unable to accurately predict the performance of the igniter, and the bridge wire igniter cannot meet the requirements, so as to improve the processing technology. Consistency level, shorter firing time, less heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

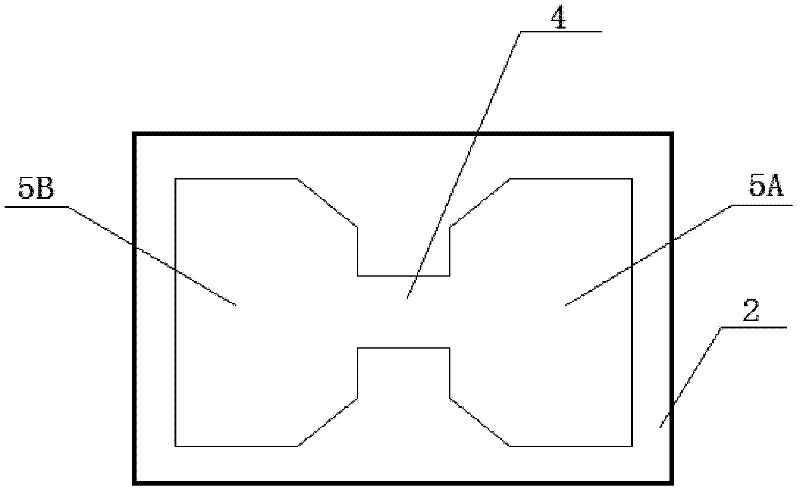

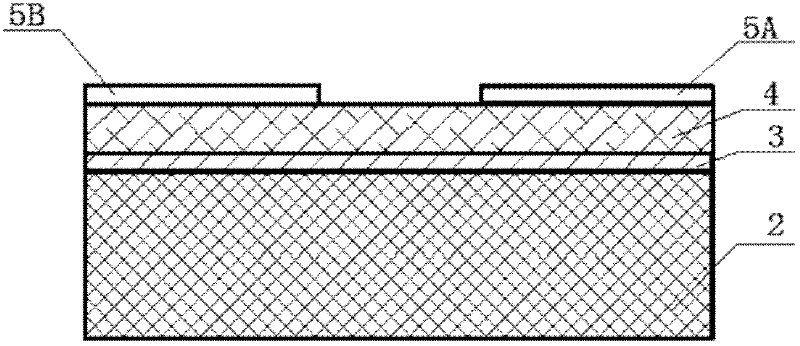

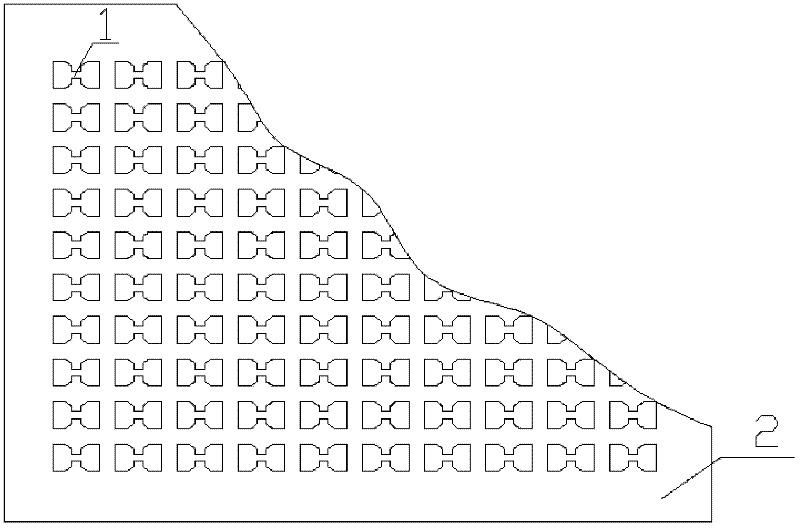

[0033] A Ni-Cr alloy film bridge igniter with low ignition voltage, such as Figure 1~3 As shown, including the substrate 2, the substrate 2 is provided with SiO 2 The isolation film 3 is provided with a thickness not greater than 5×10 -6 The igniter element 4 of m is provided with the igniter lead pad area 5A, 5B in the igniter element 4, such as Figure 4 As shown, the igniter lead pad areas 5A, 5B are connected to a lead pad area 6 on a base 7 for installing the igniter 1 through a lead wire 8; the material of the igniter element 4 is Ni-Cr alloy, wherein the ratio of Ni and Cr is 80:20. The material of the base 2 is selected from FR-4, polyimide, Al 2 o 3 At least one of them; the material of the igniter lead pad area 5A, 5B is selected from at least one of aluminum, copper, gold, and silver.

[0034] The preparation method of the Ni-Cr alloy film bridge igniter of low firing voltage of the present invention, carries out according to the following steps successively: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com